Method for detecting transverse oxygen content of burnt gas of coke oven and realizing device thereof

A technology of combustion exhaust gas and detection method, which is applied in the direction of measuring device, sampling device, program control, etc., which can solve the problems of low detection accuracy, ineffective coke oven production control, long detection cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

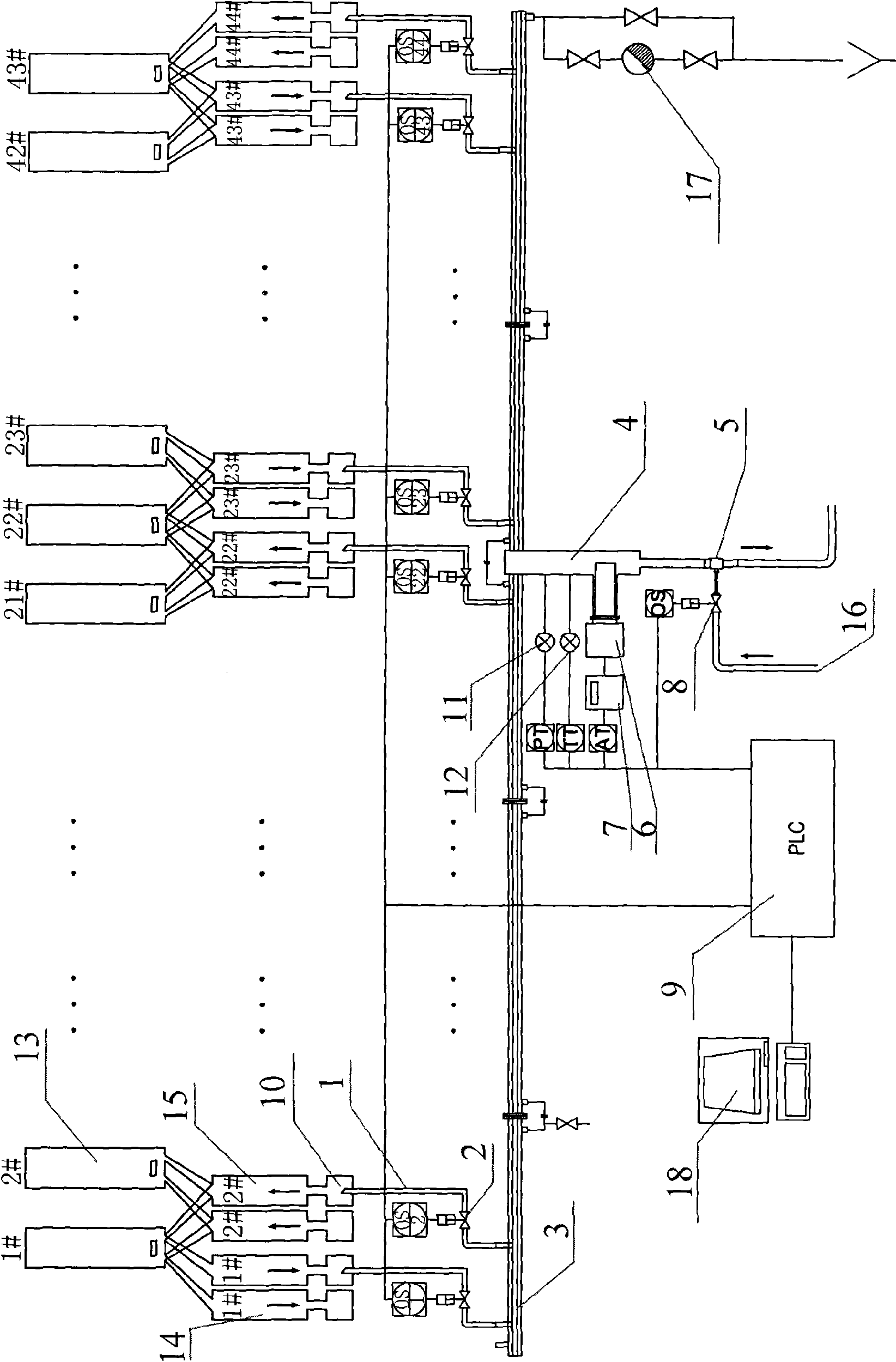

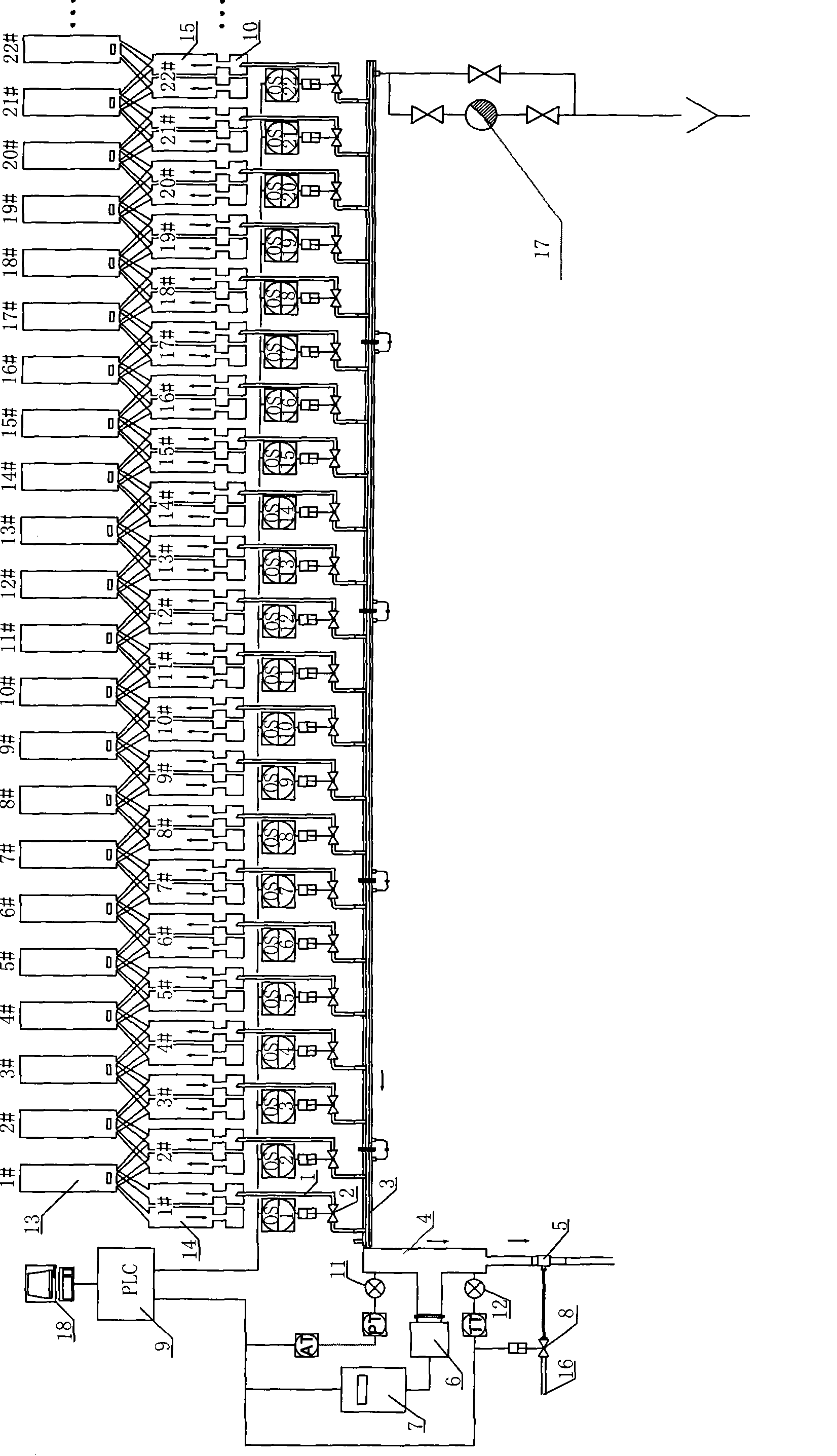

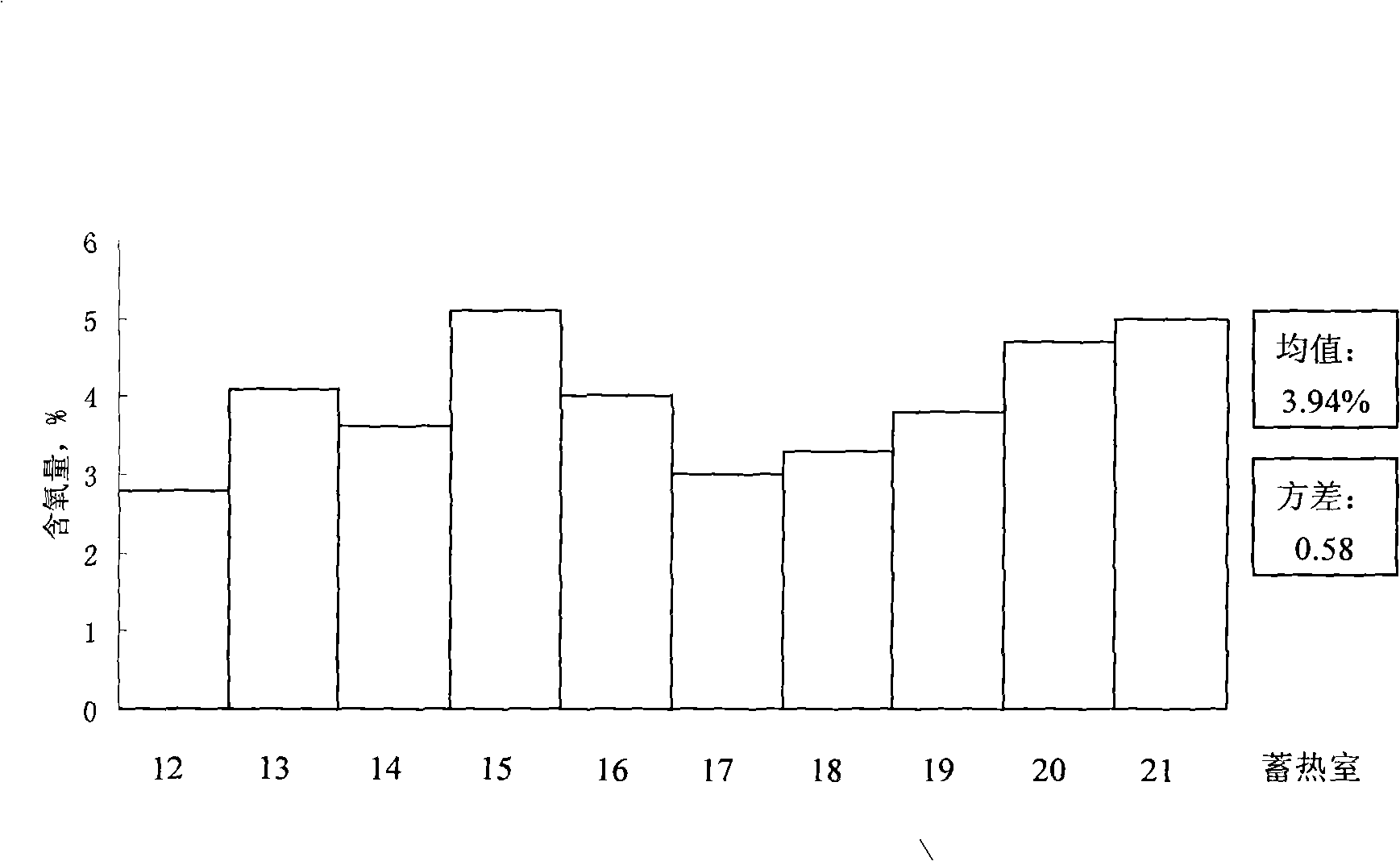

[0031] The method for detecting the horizontal oxygen content of the combustion waste gas of the coke oven provided by the present invention is to respectively sample and analyze the oxygen content of the combustion waste gas in each regenerator in a downward airflow within one reversing period of the coke oven. Its sampling and oxygen content analysis can be selected as inserting a sampling tube into the temperature measuring hole of the small flue of an air regenerator to sample the combustion exhaust gas in the regenerator, and the industrial controller automatically opens and closes each sampling tube. The solenoid valve installed on the sampling tube completes the automatic sampling of combustion exhaust gas. The combustion exhaust gas after sampling is connected to a vacuum main pipe, and a three-way pipe is used to connect the vacuum main pipe, zirconia oxygen analyzer and vacuum generator respectively. The generator generates negative pressure to extract the sampled com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com