Industrial CCD color imaging system based on super-resolution reconstruction and automatic registration

A technology of super-resolution reconstruction and automatic registration, which is applied in the field of imaging systems, can solve the problems of poor real-time performance and flexibility, large amount of calculation of reconstruction algorithms, and high cost, and achieve the effect of excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

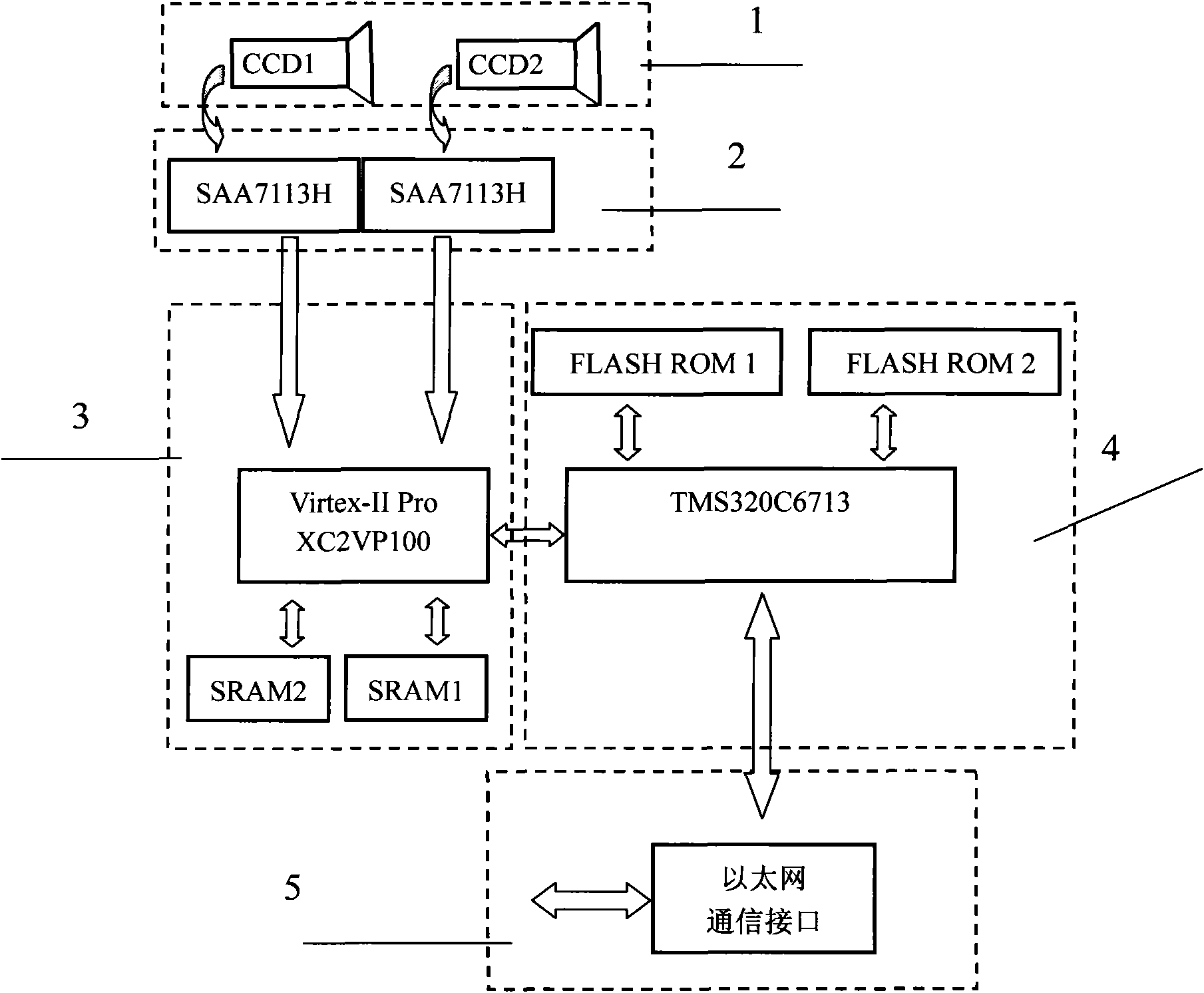

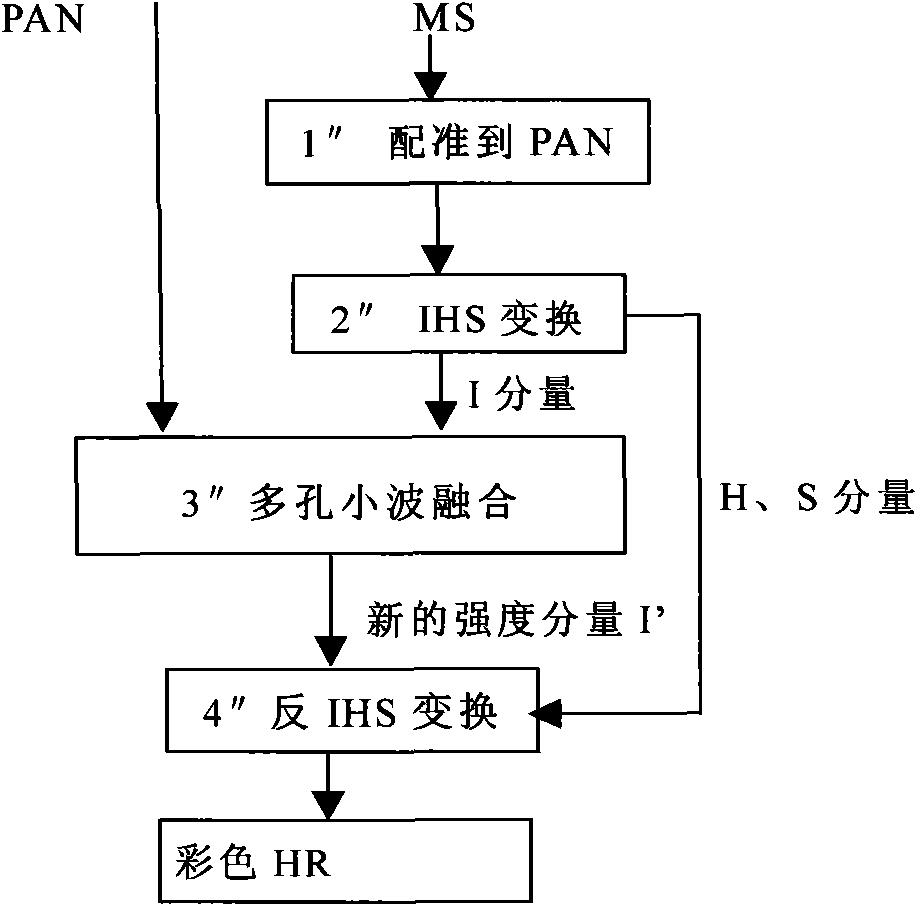

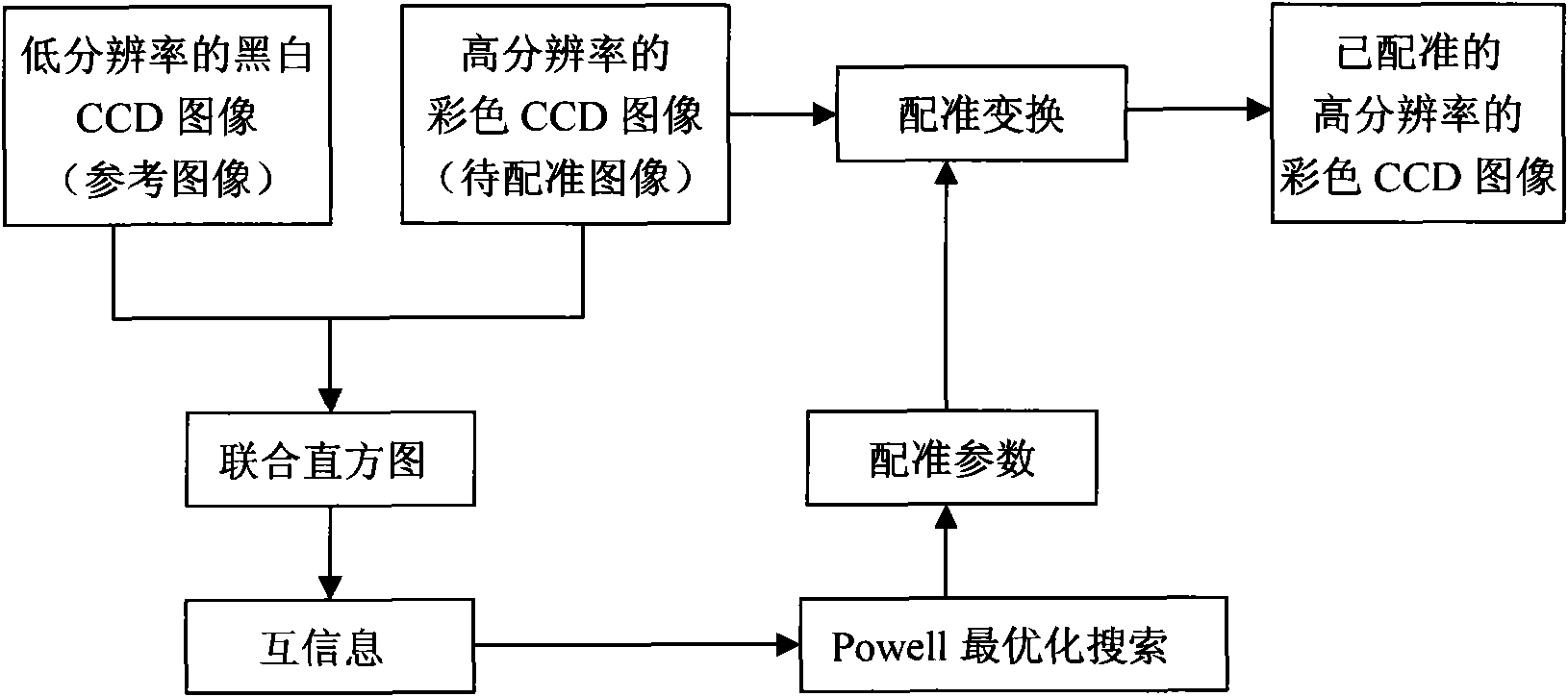

[0023] like figure 1 As shown, an industrial CCD color imaging system based on super-resolution reconstruction and automatic registration mainly consists of a color CCD camera and a black-and-white CCD camera to collect different low-resolution video acquisition modules in real time, digitize and standardize analog video The conversion module, the FPGA-based video preprocessing and automatic and reconstruction parameter registration module, the automatic registration and reconstruction algorithm realization module with DSP as the core, are composed of Ethernet communication interface modules.

[0024]The industrial CCD color imaging system for super-resolution reconstruction and automatic registration is characterized in that the color CCD camera and black-and-white CCD camera models are of low resolution and have different resolutions, and the SAA7113 programmable video signal processor performs image acquisition and format conversion, image signal amplification, anti-aliasin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com