Stable-pressure device of Zinc alloy die casting mold

A technology of die-casting molds and voltage stabilizing devices, which is applied in the field of zinc alloy die-casting molds and can solve problems such as edge overflow, deformation damage, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

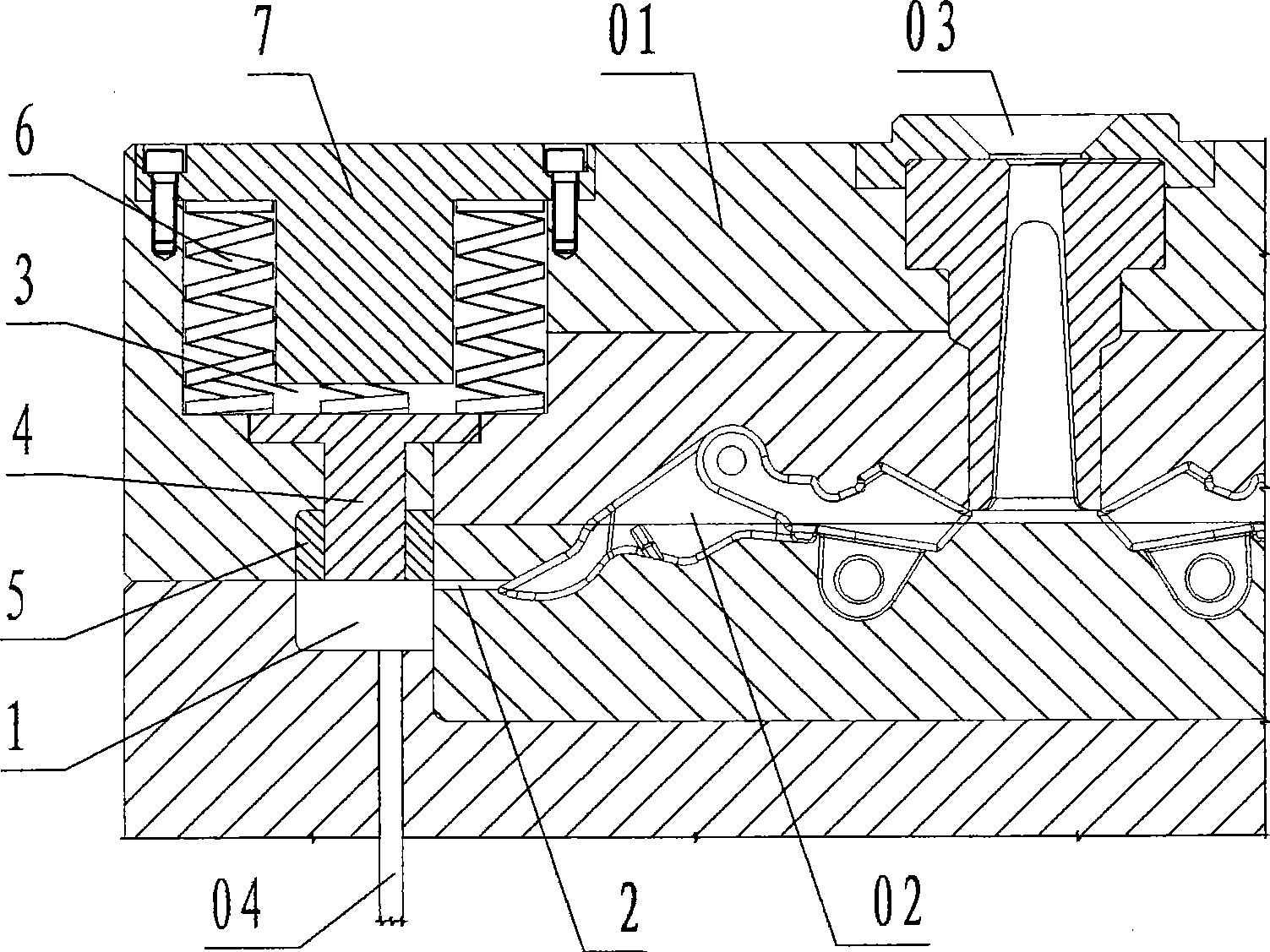

[0013] refer to figure 1 , a voltage stabilizing device for a zinc alloy die-casting mold of the present invention, comprising a material chamber 1, a flow channel 2, a mechanism chamber 3, a piston 4, a piston sleeve 5, a spring 6, and a limit gland 7, wherein: the The material chamber 1 is a groove located on the parting surface of the movable mold of the mold 01 and adjacent to the cavity insert; the flow channel 2 is provided on the parting surface of the movable mold cavity of the mold 01, connecting the cavity 02 A channel that communicates with the material chamber 1; the mechanism chamber 3 is set in the fixed mold of the mold 01, and the center of the bottom is provided with a cylindrical step-shaped groove with a through hole, and the large step of the upper notch is located in the fixed mold. On the upper end surface, the center of the groove bottom is provided with a cylindrical step through hole passing through the fixed template to the parting surface of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com