Reverse side lifting device in single-side welding double-side molding welding mechanism

A single-sided welding double-sided, welding mechanism technology, applied in auxiliary devices, welding accessories, welding equipment and other directions, can solve the problems of low production efficiency and high labor intensity of workers, and achieve a simple structure, reduce labor intensity, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

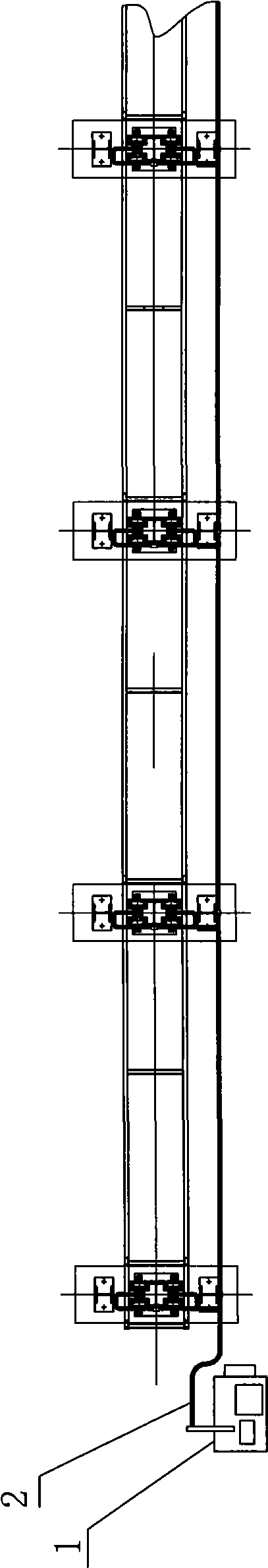

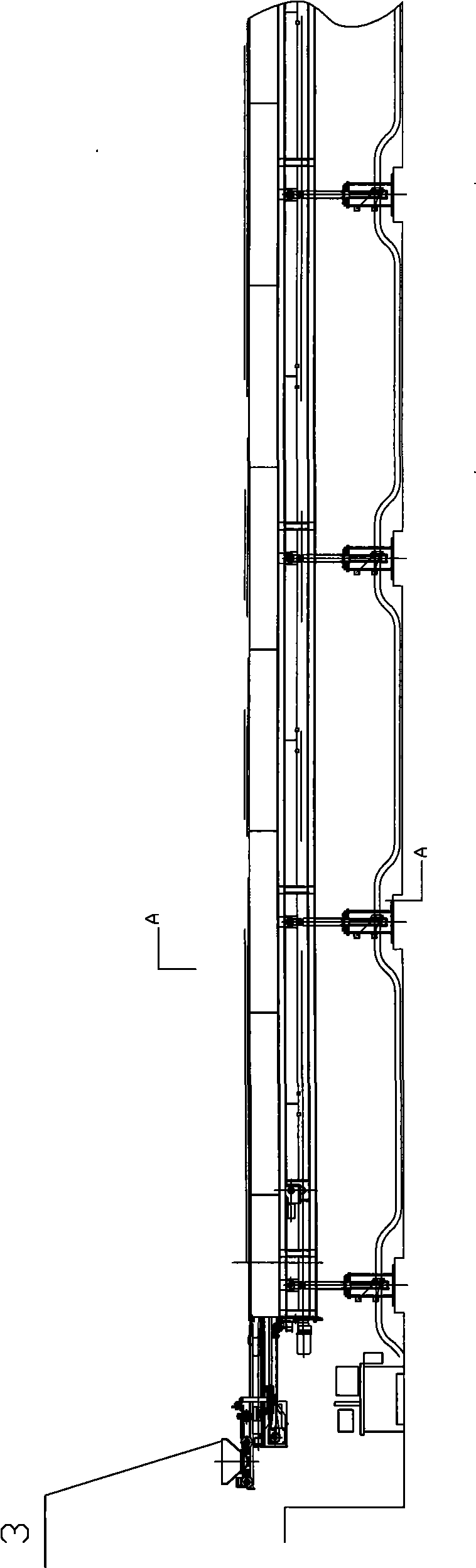

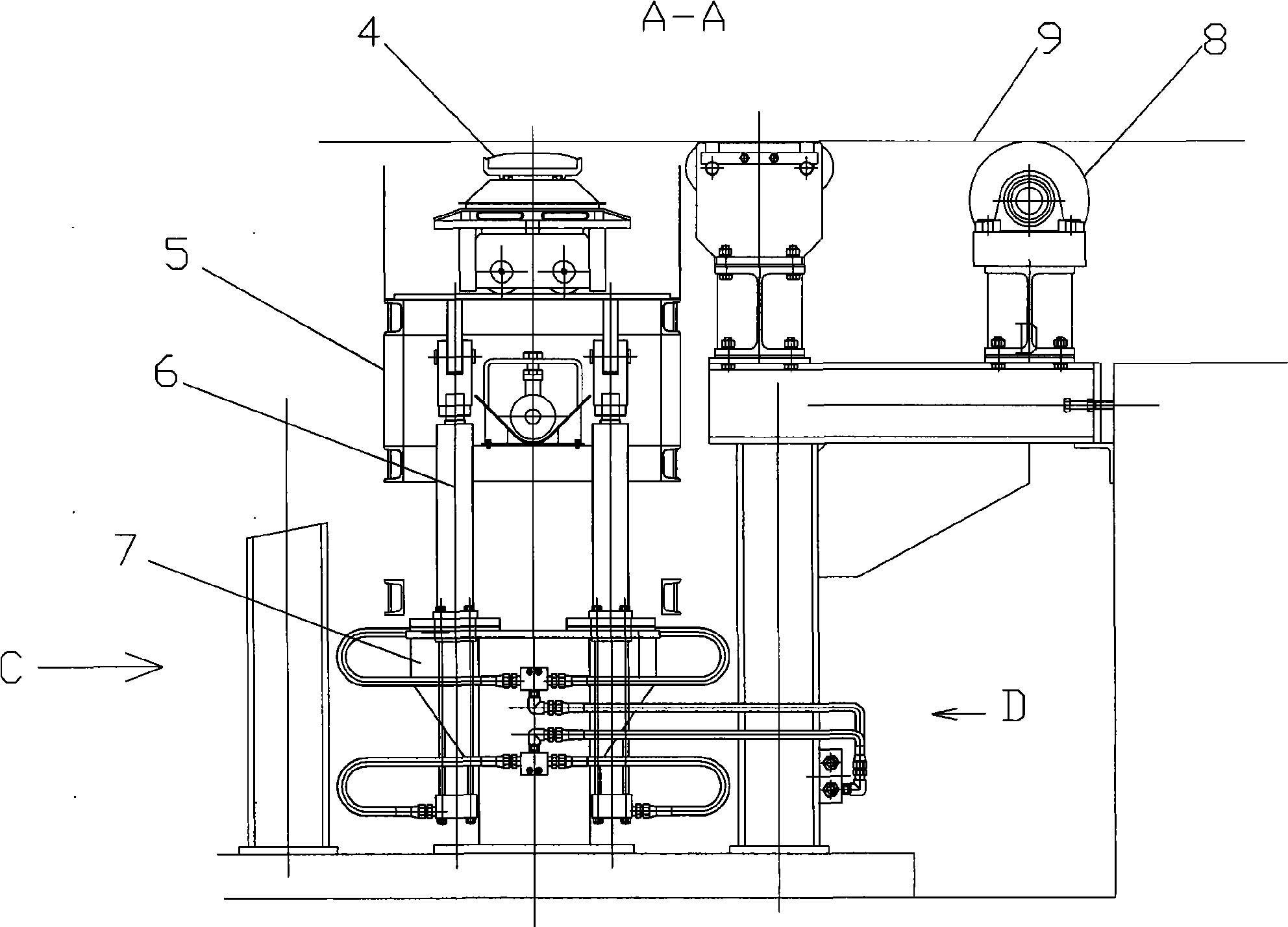

[0013] The present invention is mainly composed of a hydraulic station 1, a hydraulic rubber hose 2, a support frame 5, a hydraulic cylinder 6, a hydraulic cylinder stand 7 and a roller 8 and the like.

[0014] The present invention adopts hydraulic cylinder stand 7 to be arranged in a straight line, and multiple groups of hydraulic cylinders 6 are arranged on each hydraulic cylinder stand 7, and support frame 5 is connected above hydraulic cylinder 6, and reverse copper plate liner device 4 is arranged on support frame 5. Rollers 8 are installed on the cylinder stand 7, and multiple groups of hydraulic cylinders 6 are connected by hydraulic hoses 2, and the hydraulic hoses 2 are connected with the hydraulic cylinder stand 7.

[0015] The backing device 4 of the reverse copper plate (consists of a reverse copper plate, a connecting shaft, and a copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com