Method for generating power by high efficient floating type wave energy by rubbing

A wave energy, floating technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problem that wave energy power generation technology cannot efficiently collect and convert wave energy in a large area, and achieve good power generation effect and work. Smooth, efficient capture and transition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

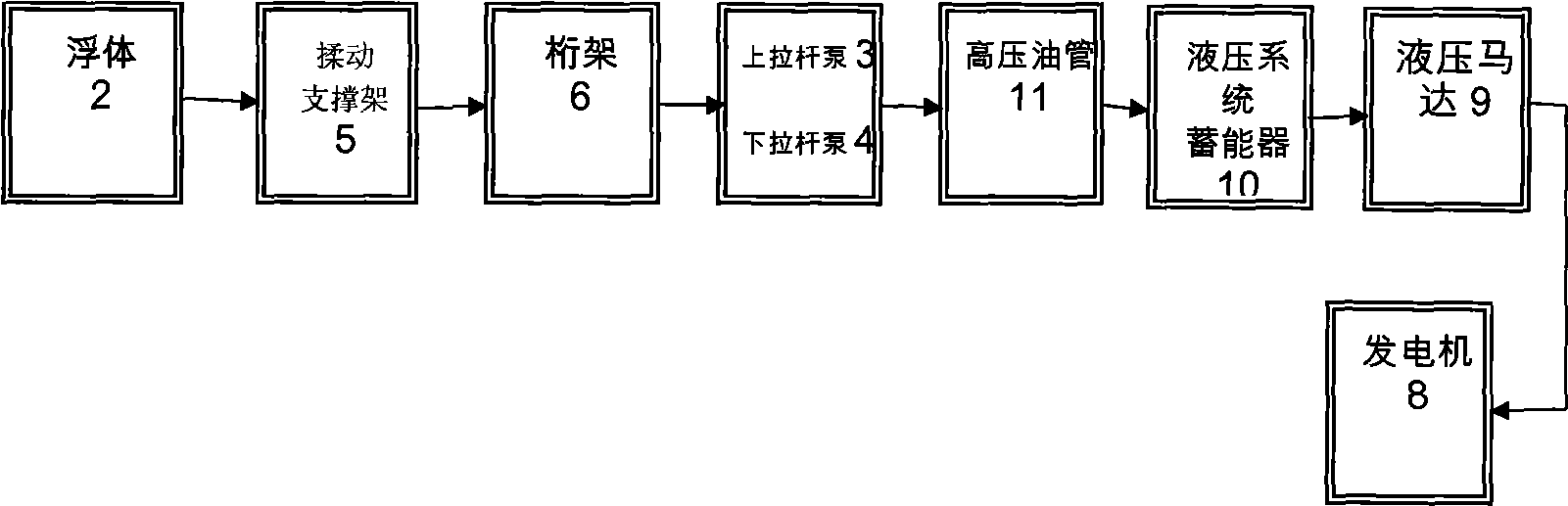

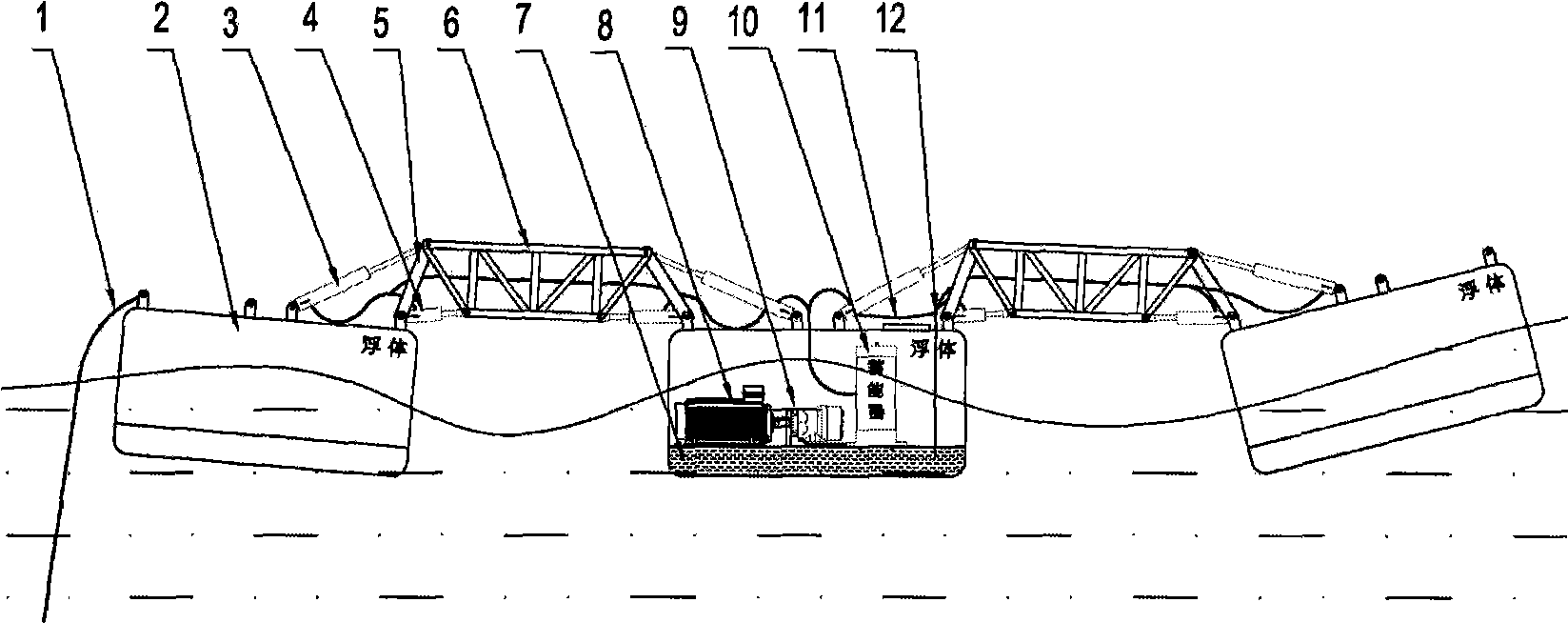

[0026] Such as figure 2 As shown, all devices are safely and organically connected together, and the whole device floats on the sea. In this specific embodiment, the mooring cable system 1 flexibly positions the entire device in the working sea area, and the floating body 2 is subjected to the fluctuation of wave energy, forcing it to form a relatively flexible swing with the kneading support frame 5 and the truss 6, forcing the hinge The distance between the hinge points at both ends of the connected upper rod pump 3 and lower rod pump 4 changes, so that the liquid inside the upper rod pump 3 and lower rod pump 4 is under strong pressure, and the high-pressure liquid is sent to the hydraulic system through the high-pressure oil pipe 11 for energy storage The pressure leveling process is carried out in the device 10, and then the liquid with stable pressure is sent into the hydraulic motor 9 to drive the rotation, thereby driving the generator 8 to rotate and generate electri...

specific Embodiment approach 2

[0027] The anchor cable system and the first floating body can be removed, the truss 6 can be directly installed on the shore platform, and the installation of other components remains unchanged.

specific Embodiment approach 3

[0028] The structures described in Embodiment 1 can also be arranged in a criss-cross pattern on the sea surface according to the requirements of power generation, and dozens or even tens of thousands of them can be installed to achieve an ideal power generation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com