Fuel container and solid fuel

A solid fuel and fuel container technology, applied in the direction of solid fuel, fuel, solid heating fuel, etc., can solve the problems of odor emission, heat absorption effect reduction, inability to peel off, etc., and achieve the effect of suppressing a sharp temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

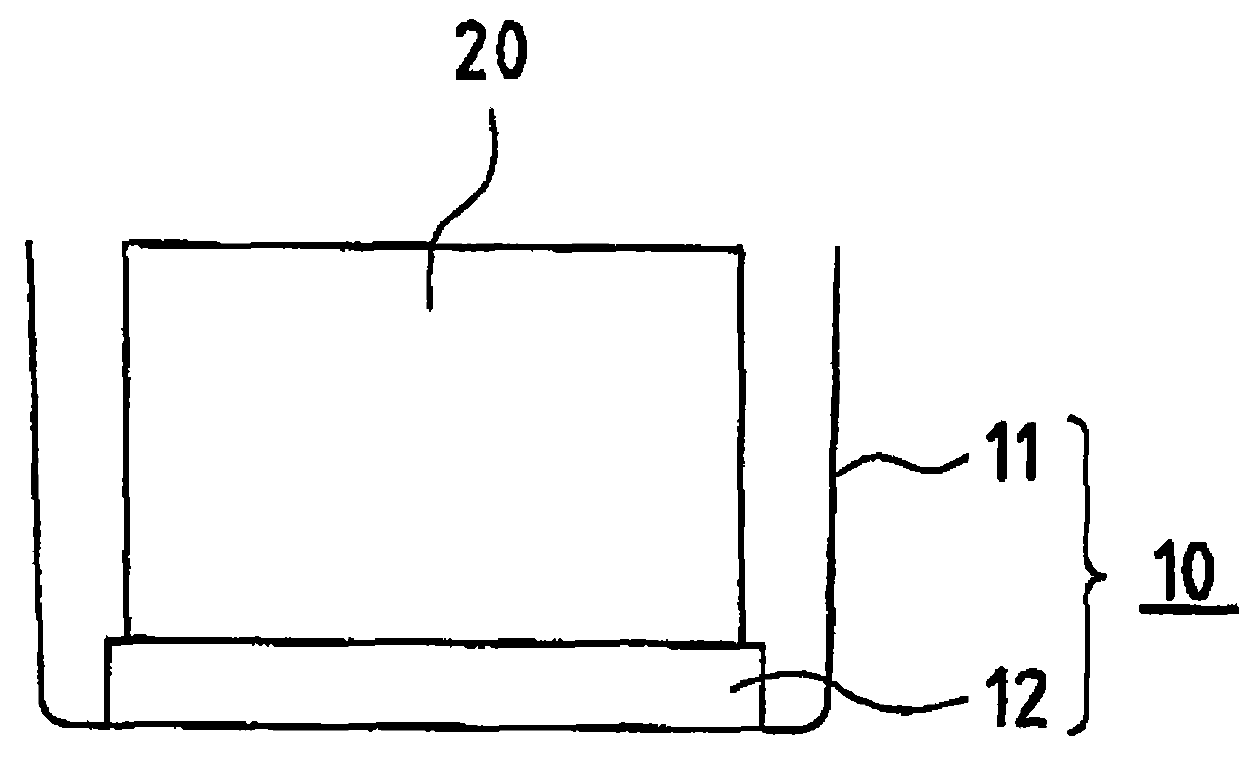

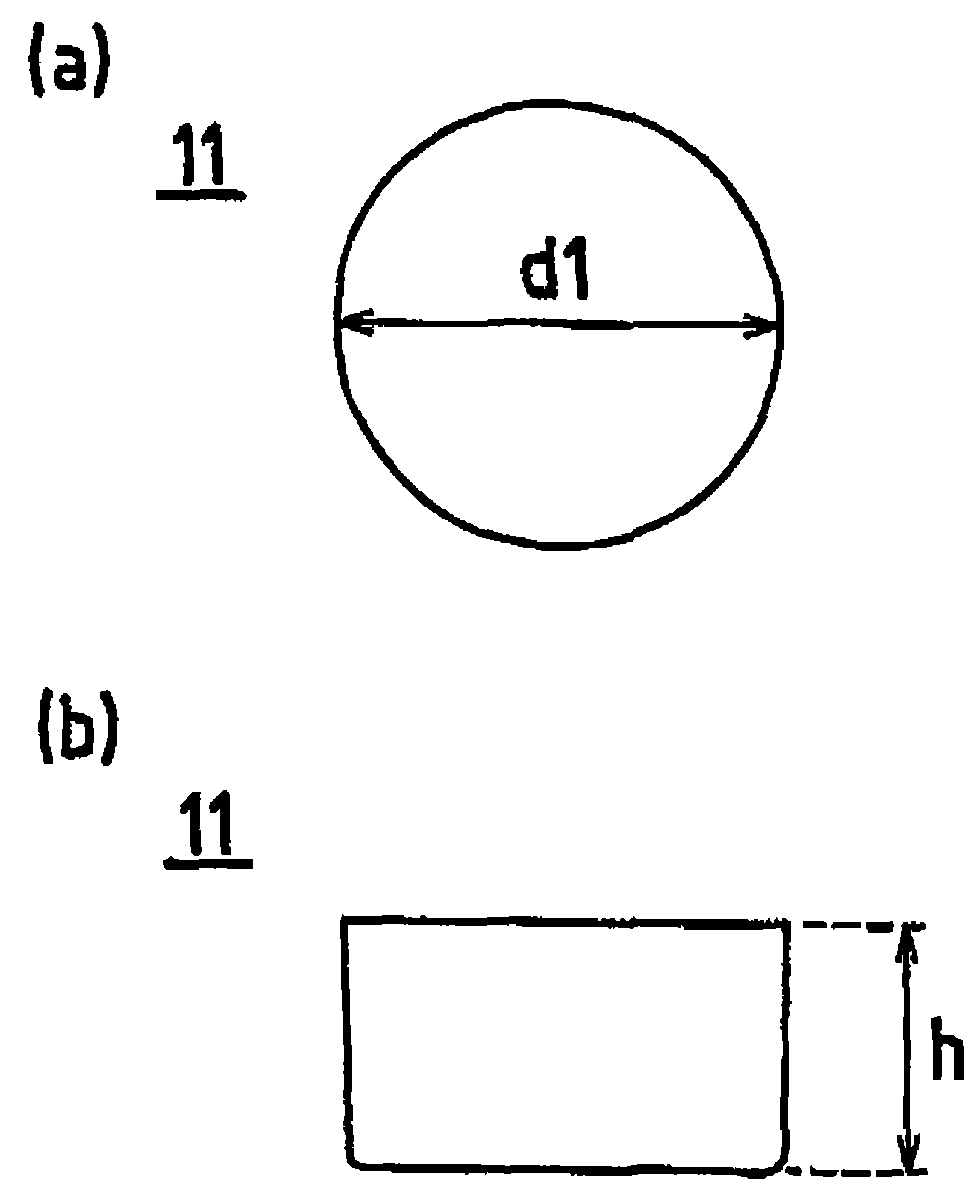

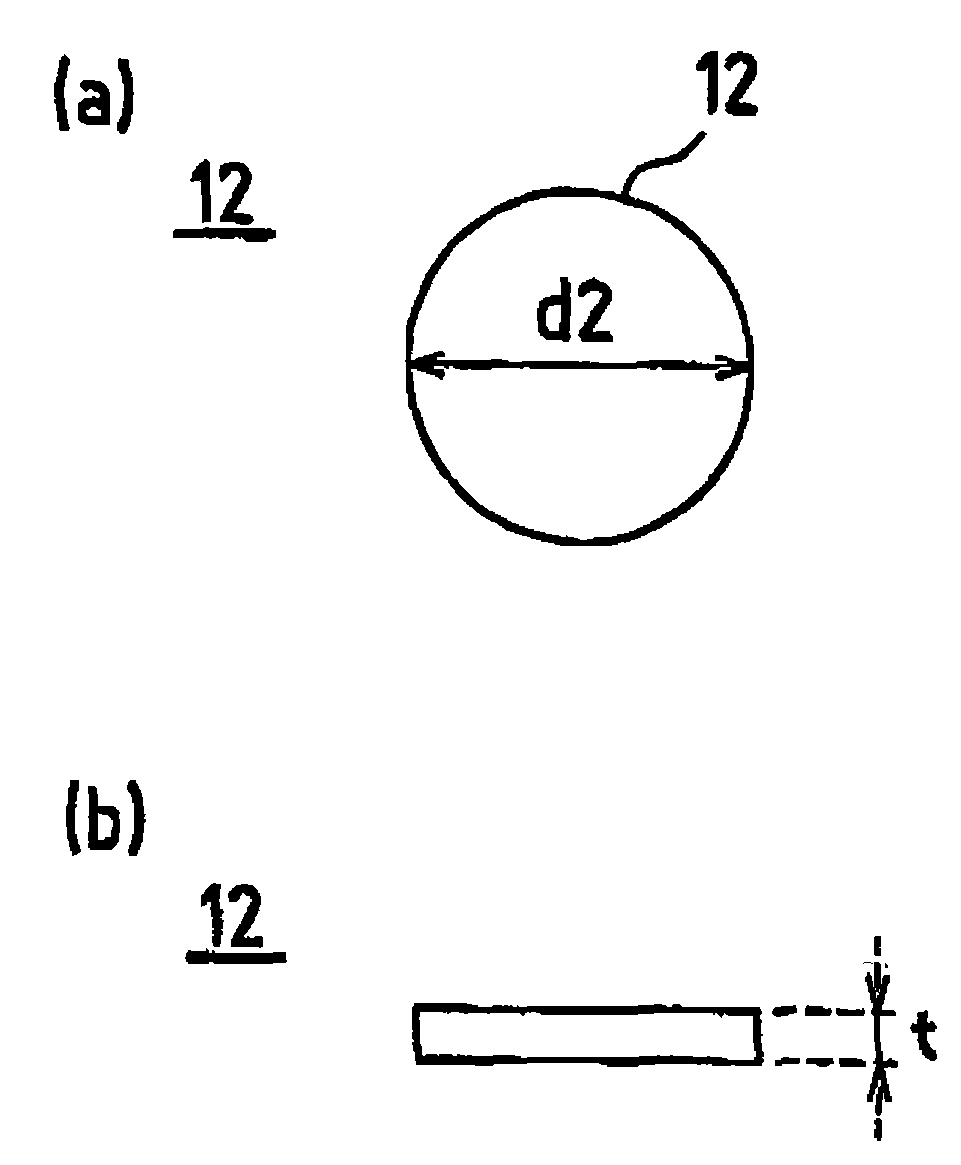

[0036] figure 1 It is a perspective side view showing a schematic configuration of a fuel container according to Embodiment 1 of the present invention. also, figure 2 yes figure 1 (a) bottom view and (b) side view of the container body of the fuel container shown in image 3 yes figure 1 (a) bottom view and (b) side view of the heat absorber of the fuel container shown in . also, Figure 4 yes figure 1 A perspective side view of a usage example of the fuel container shown in .

[0037] The fuel container 10 according to Embodiment 1 of the present invention includes a container body 11 that accommodates the solid fuel 20 and a heat absorber 12 that absorbs heat generated at the end of combustion of the solid fuel 20 .

[0038] The container main body 11 is formed in the shape of a container with an upper opening capable of accommodating the solid fuel 20 , specifically, in a cylindrical shape with a bottom.

[0039] The heat absorber 12 is formed in a disc shape on wh...

Embodiment 1~6、 comparative example 1

[0049] The fuel container 10 according to the present embodiment was placed on the center bottom of the small furnace 40, and a pot 50 filled with 1000 g of water was mounted on the upper part of the opening of the small furnace 40, and a combustion test of the solid fuel 20 was carried out. In addition, the combustion test is carried out as follows. A thermocouple is installed between the solid fuel 20 and the heat absorbing body 12, and the maximum attained temperature of this part is measured, that is, the maximum attained temperature between the ignition of the solid fuel 20 and the natural extinguishment is measured. temperature. In addition, the state of smoke generation during combustion and after extinguishment, and the state of the soap component (solid fuel 20 ) after extinguishment were evaluated.

[0050] As the pot 50, a stainless steel pot with a diameter of 175 mm and a height of 85 mm was used. In addition, as the solid fuel 20, a cylindrical solid fuel 20 hav...

Embodiment approach 2

[0075] Figure 5 It is a perspective side view showing a schematic configuration of a fuel container according to Embodiment 2 of the present invention.

[0076] The fuel container 10 according to Embodiment 2 of the present invention has almost the same structure as the fuel container 10 according to Embodiment 1, and includes a container body 11 for accommodating the solid fuel 20 and a heat absorber for absorbing heat generated at the end of combustion of the solid fuel 20. Body 12. Hereinafter, points different from Embodiment 1 will be mainly described.

[0077] The container body 10 is formed in the same shape as the first embodiment in the shape of a container with an open top, specifically, in the shape of a bottomed cylinder. In addition, the size of the container main body 10 is set to the size which can accommodate the bottom part of the heat absorber 12 formed in the container shape shown below.

[0078] The heat absorber 12 is formed in the shape of a container...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com