Light-sensitive resin composition, light-sensitive resin transfer material, photospacer

A technology of photosensitive resin and transfer material, applied in the field of photosensitive resin composition, can solve problems such as transfer printing, and achieve the effect of preventing uneven display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0160] (embodiment 1): transfer method

[0161] —Production of photosensitive resin transfer material for gap material—

[0162] On a polyethylene terephthalate film temporary support (PET temporary support) with a thickness of 75 μm, apply a coating solution for a thermoplastic resin layer composed of the following formulation A, and dry it to form a dry layer thickness A thermoplastic resin layer of 18.0 μm.

[0163] [Recipe A of Coating Liquid for Thermoplastic Resin Layer]

[0164] ・Methyl methacrylate / 2-ethylhexyl acrylate / benzyl methacrylate / methacrylic acid copolymer (=55 / 11.7 / 4.5 / 28.8 [molar ratio], weight average molecular weight 90,000)...25.0 parts

[0165] ・Styrene / acrylic acid copolymer …58.4 parts

[0166] (=63 / 37 [molar ratio], weight average molecular weight 8,000)

[0167] 2,2-bis[4-(methacryloxypolyethoxy)phenyl]propane

[0168] …39.0 servings

[0169] ·Surfactant 1…10.0 parts

[0170] ・Methanol …90.0 parts

[0171] 1-meth...

Embodiment 2

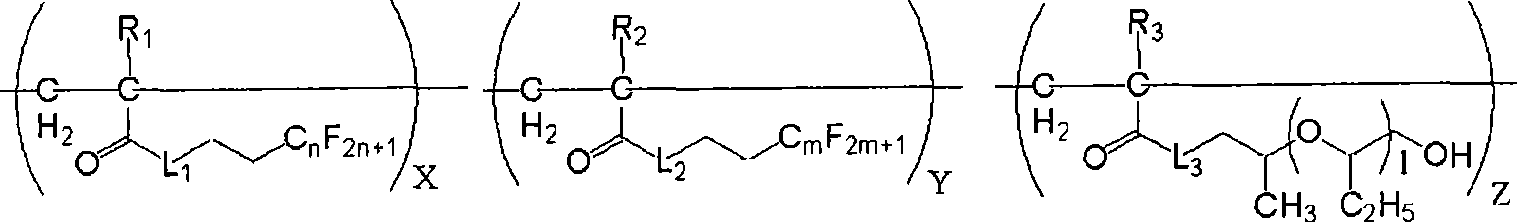

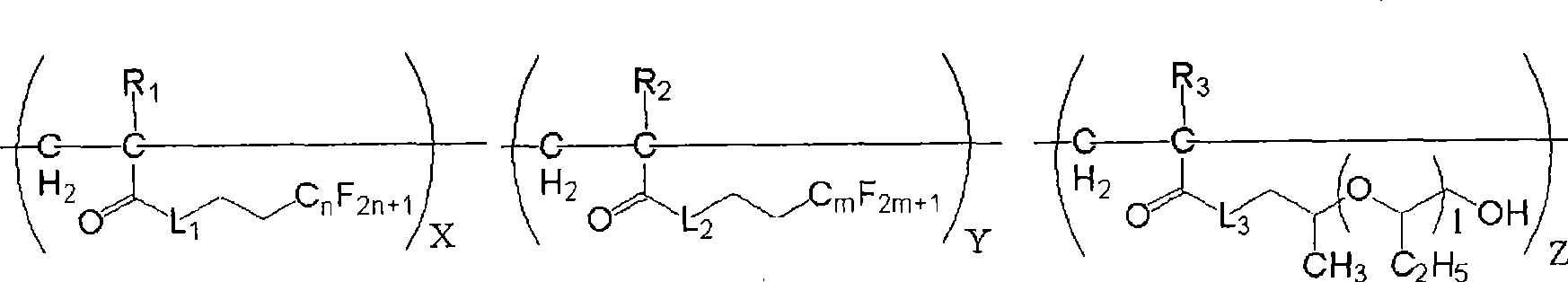

[0344] In Example 1, the fluorine-containing compound 1 is changed to the following fluorine-containing compound 2 (in general formula (A), n=8, m=6, 1=8, R 1 ~R 3 =—CH 3 , L 1 ~ L 3 =-O-, X=Y=25%, Z=50%, Mw=15000), except that, it carried out similarly to Example 1, and obtained the liquid crystal display device.

Embodiment 3

[0346] In Example 1, the fluorine-containing compound 1 is changed to the following fluorine-containing compound 3 (in general formula (A), n=4, m=2, 1=8, R 1 ~R 3 =—CH 3 , L 1 ~ L 3 =—O—, X=Y=25%, Z=50%, Mw=15000), and the liquid crystal display device was obtained in the same manner as in Example 1 except that.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com