Electro-hydraulic servo operating mechanism of high-voltage circuit breaker

A high-voltage circuit breaker, electro-hydraulic servo technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, servo motors, etc., can solve problems such as inability to apply, inability to achieve adjustment and control, and inability to achieve load matching performance, etc. Achieve the effect of improving the overall opening and closing capacity, good electrical, opening and closing load matching characteristics, and small opening and closing impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The details of the present invention are given below by describing the embodiments in conjunction with the accompanying drawings.

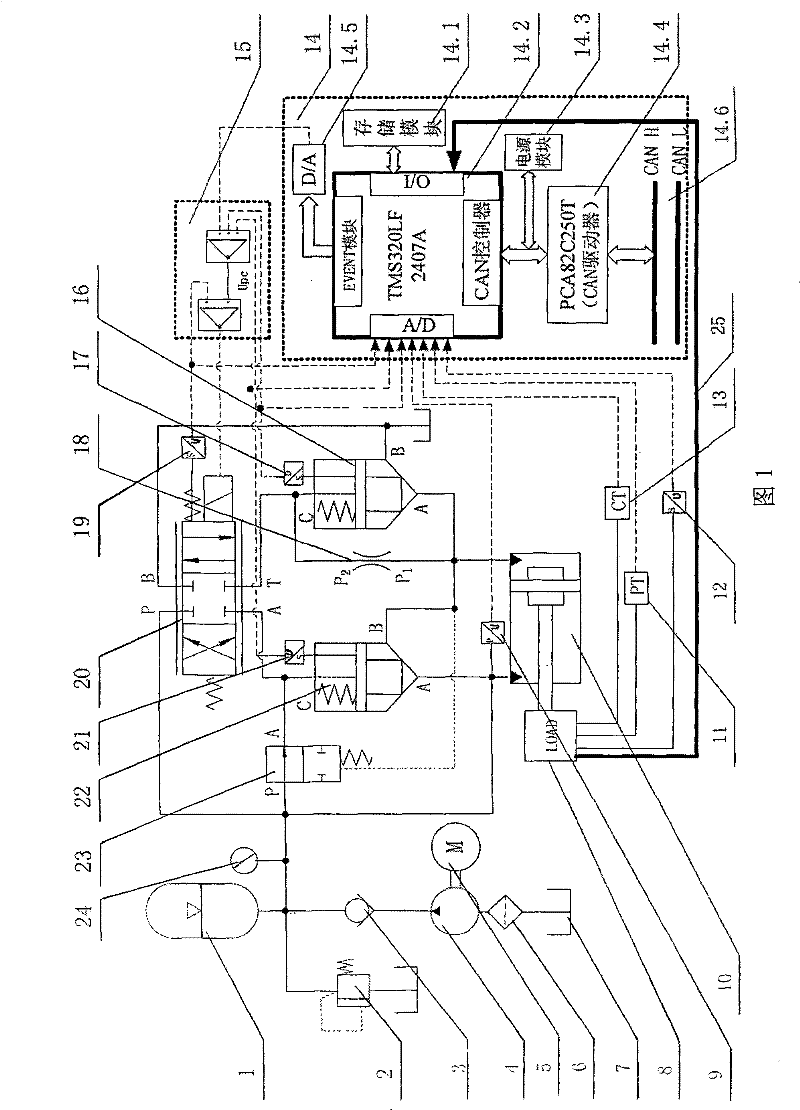

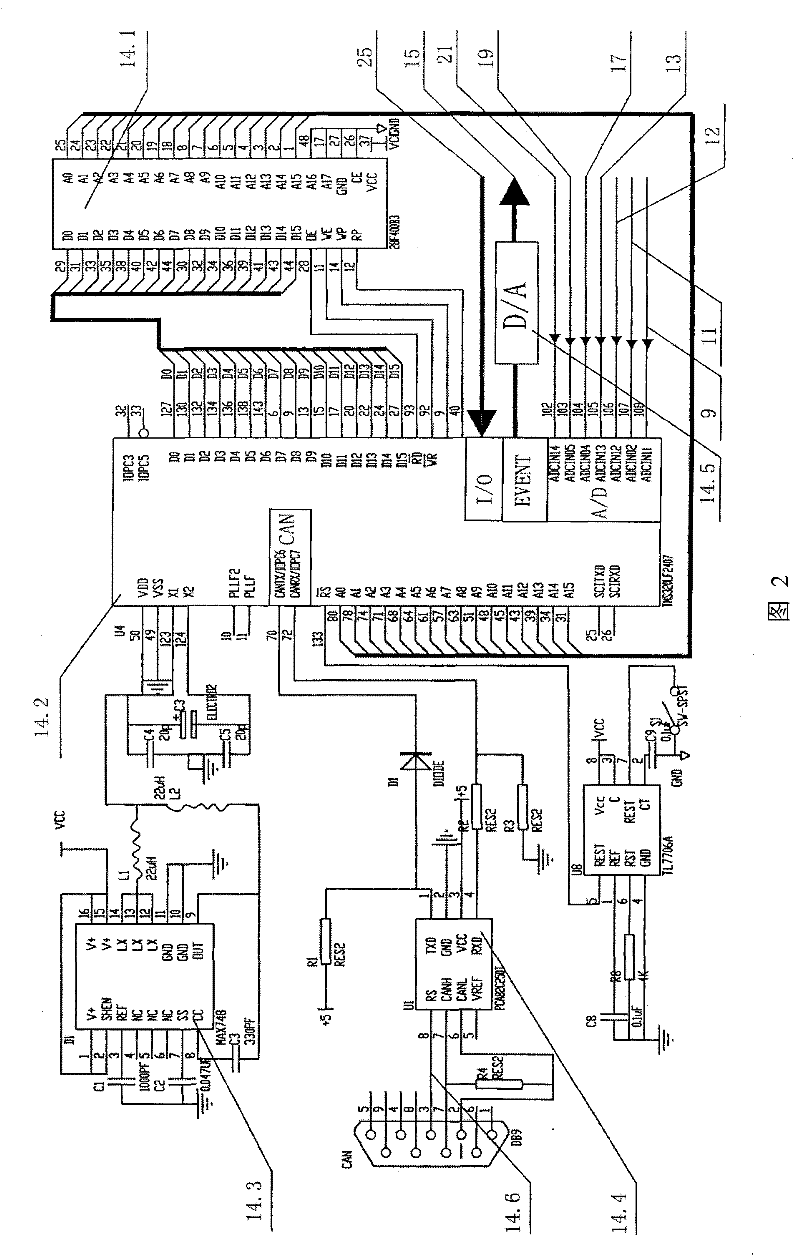

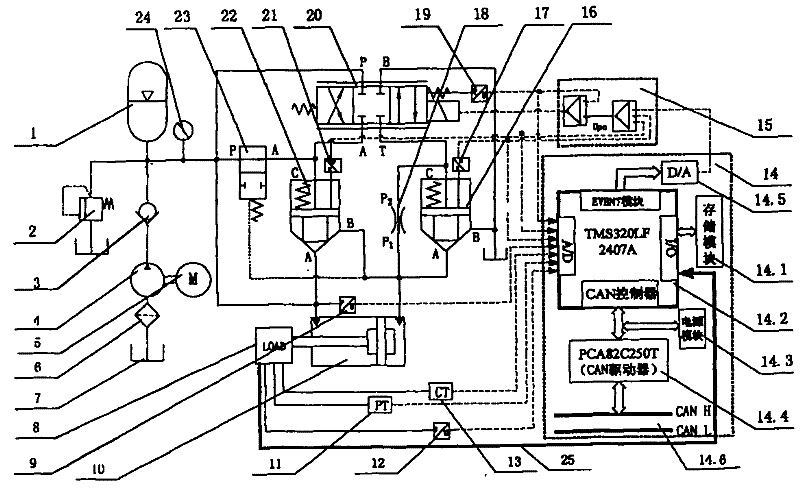

[0016] Such as figure 1 As shown, the present invention includes an electro-hydraulic servo hydraulic system and an intelligent control device; wherein

[0017] 1) Electro-hydraulic servo hydraulic system: It consists of an oil source part and a control drive part. The high-pressure oil provided by the oil source part is divided into three routes, the first route is connected to the P port of the pilot stage servo valve 20, and the second route is connected to the normally open The P port of the type two-position two-way hydraulic control ball valve 23 is connected, and the third line is connected with the rod cavity of the hydraulic cylinder 10, the pressure sensor 9 and the A port of the closing cartridge valve 22; the B port of the pilot stage servo valve 20, the opening port The port B of the cartridge valve 16 is connected to the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com