Manufacturing method of figured cloth slippers

A production method and technology of slippers, applied in soles, footwear, applications, etc., can solve problems such as unsightly appearance, and achieve the effect of good flexibility, unique ornamental value, and rich colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific steps of the present invention are to cut or tear the pure cotton cloth into 6-8cm wide and 1.5m long cloth strips, tear the pure cotton cloth into 6-8cm wide and 3-4m long cloth strips; Cut into 8cm wide cloth strips, twist them into two cigarette-thick cloth ropes, the ropes are 1.2m long, and prepare two 1.2m long nylon ropes.

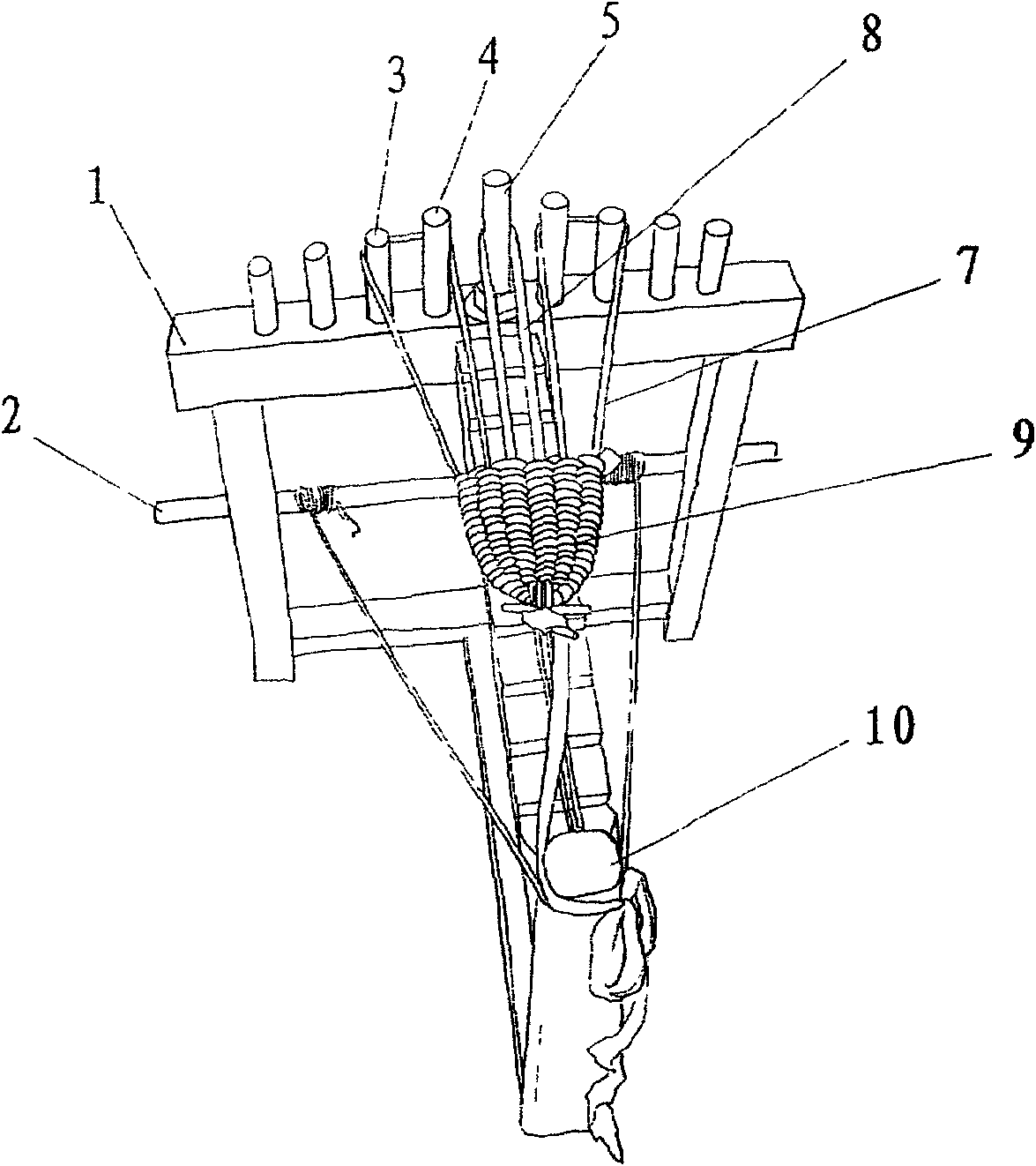

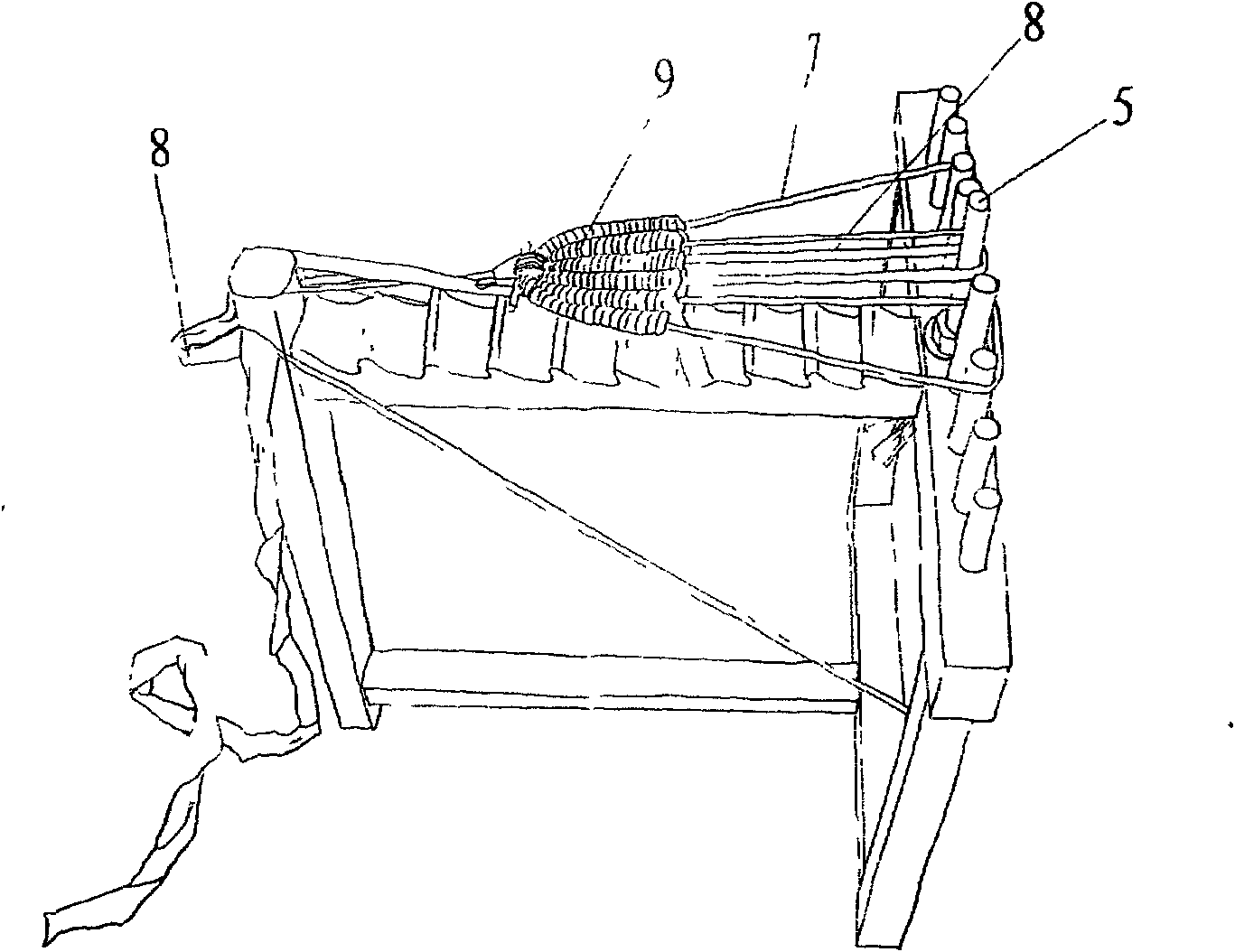

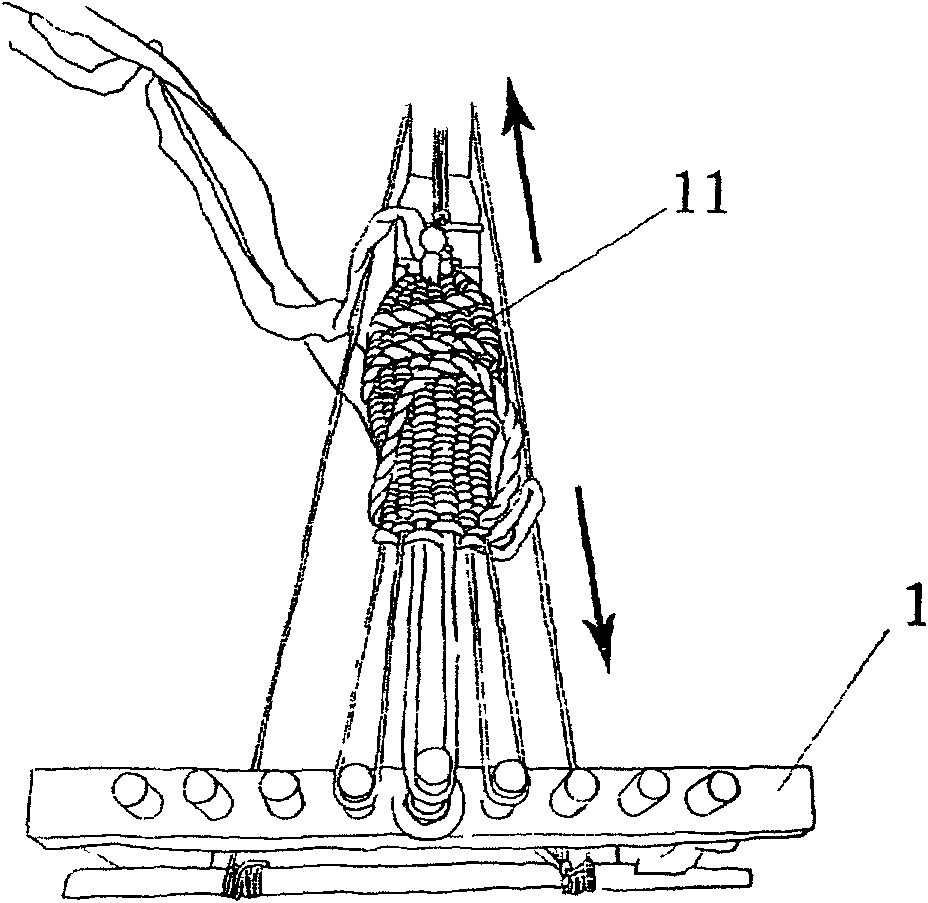

[0021] refer to figure 1 , 2 , two nylon ropes 7 are fixed on the two side columns 3, 4 and the end column 10 of the ladder frame, and the two ends are fixed on the crossbar of the ladder frame, and the blended fabric rope 8 is fixed on the middle column 5 and the end column of the ladder frame. Fixed on the head post 10. Twist the cloth strip of the 6cm wide strip into a rope with the right hand, and the rope starts at the toe of the shoe and weaves the sole 9 in the manner shown in the figure toward the heel.

[0022] Wrap a cloth strip 6-8cm wide and 1.5m long around the nylon rope on the right side of the sole, then twist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com