Aplanatic light path control device of laser cutter

A laser cutting machine and control device technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of complex structure, high cost, low precision, etc., and achieve stable movement, improved cutting quality, and compact installation space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further illustrate the concrete structure of the present invention below in conjunction with accompanying drawing:

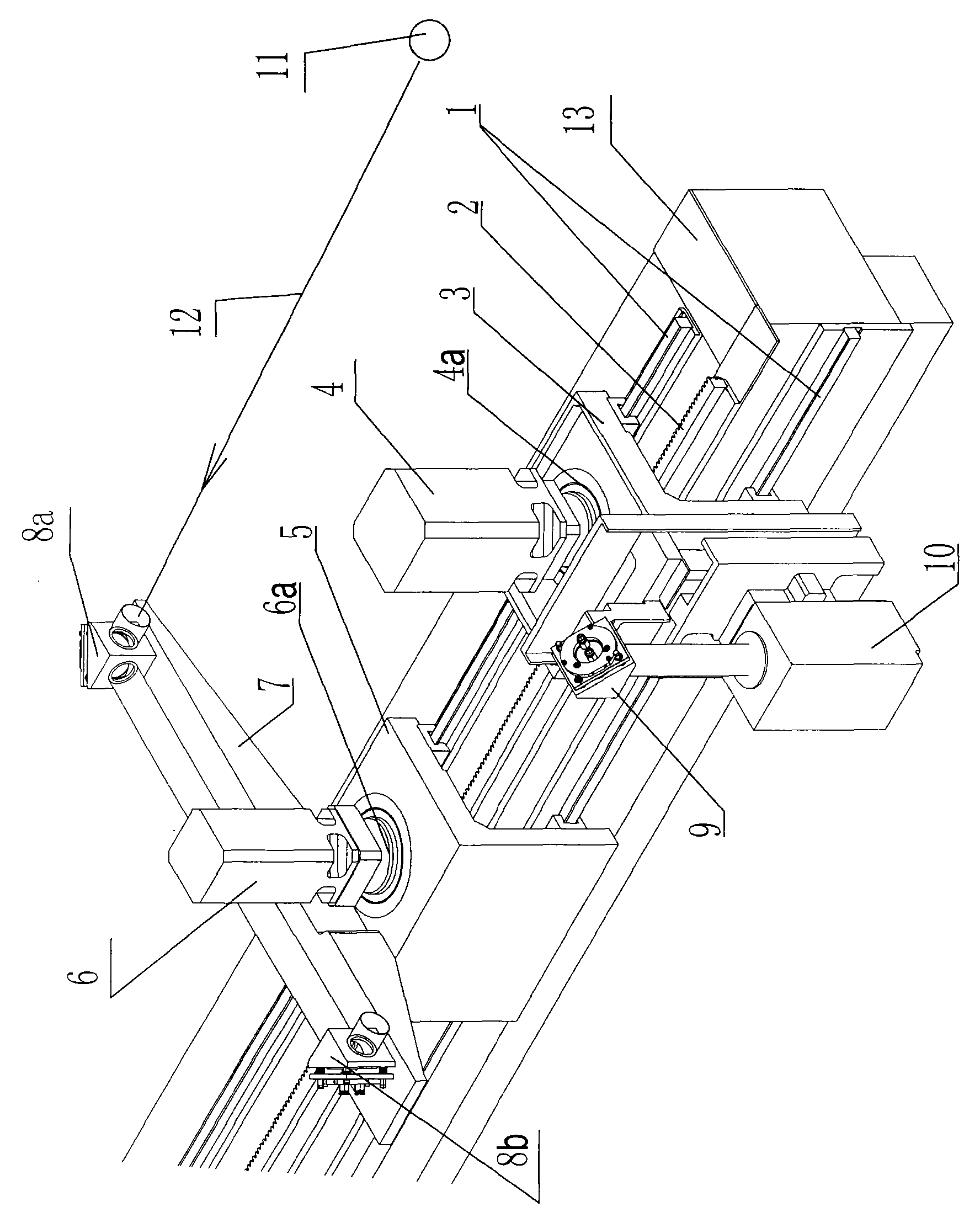

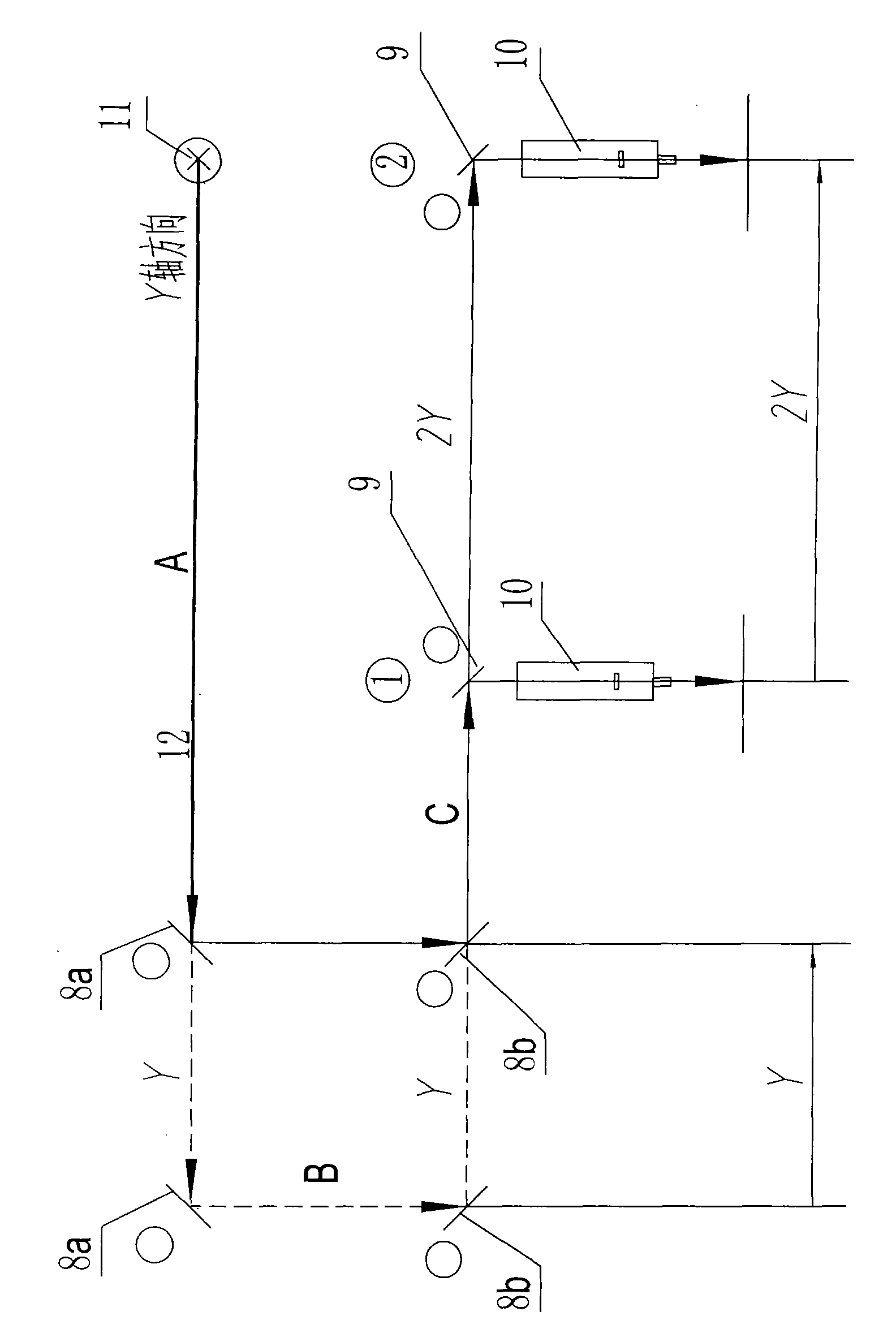

[0014] figure 1 It is a schematic diagram of the overall structure of the present invention in the application state:

[0015] The present invention mainly comprises the laser source 11, the compensating reflector mechanism on the optical path 12 and its compensating mechanism drive, the laser cutting head reflector 9 on the laser cutting head 10, the driving 4 of the laser cutting head, the compensating reflector mechanism and the laser cutting head Share a linear guide rail pair 1 on the crossbeam 13, and the compensation drive and the laser cutting head drive the same transmission pair 2 on the shared crossbeam.

[0016] The linear guide rail pair 1 and the rack 2 are fixed on the beam 13, and the sliding seat 3 is installed on the linear guide rail pair 1, matches with the linear guide rail pair 1, and can slide on the linear guide rail pair 1. Slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com