Assembling stand for assembling tank type vessel and assembling method

A technology for assembly tables and containers, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of long time for manual operation of head and cylinder assembly, unable to meet large-scale production, and affect product quality and other issues to achieve the effect of avoiding accidental damage, high reliability, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

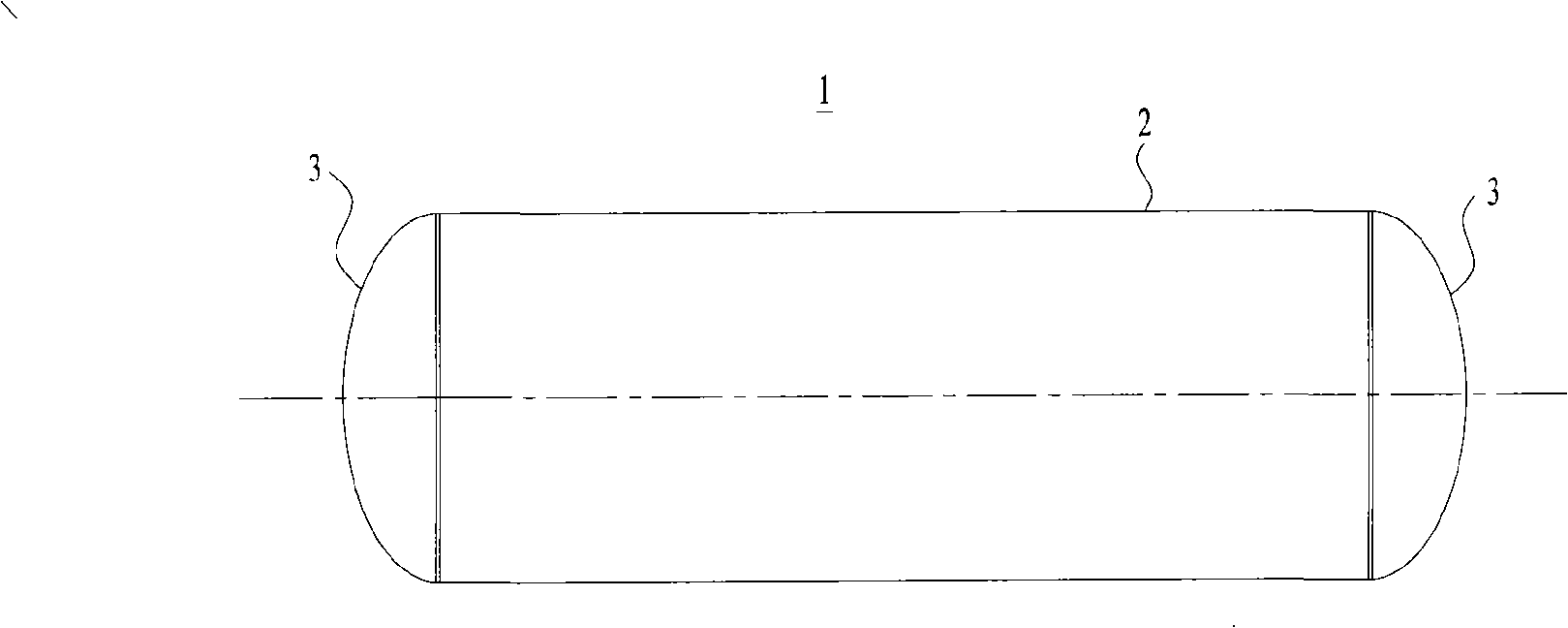

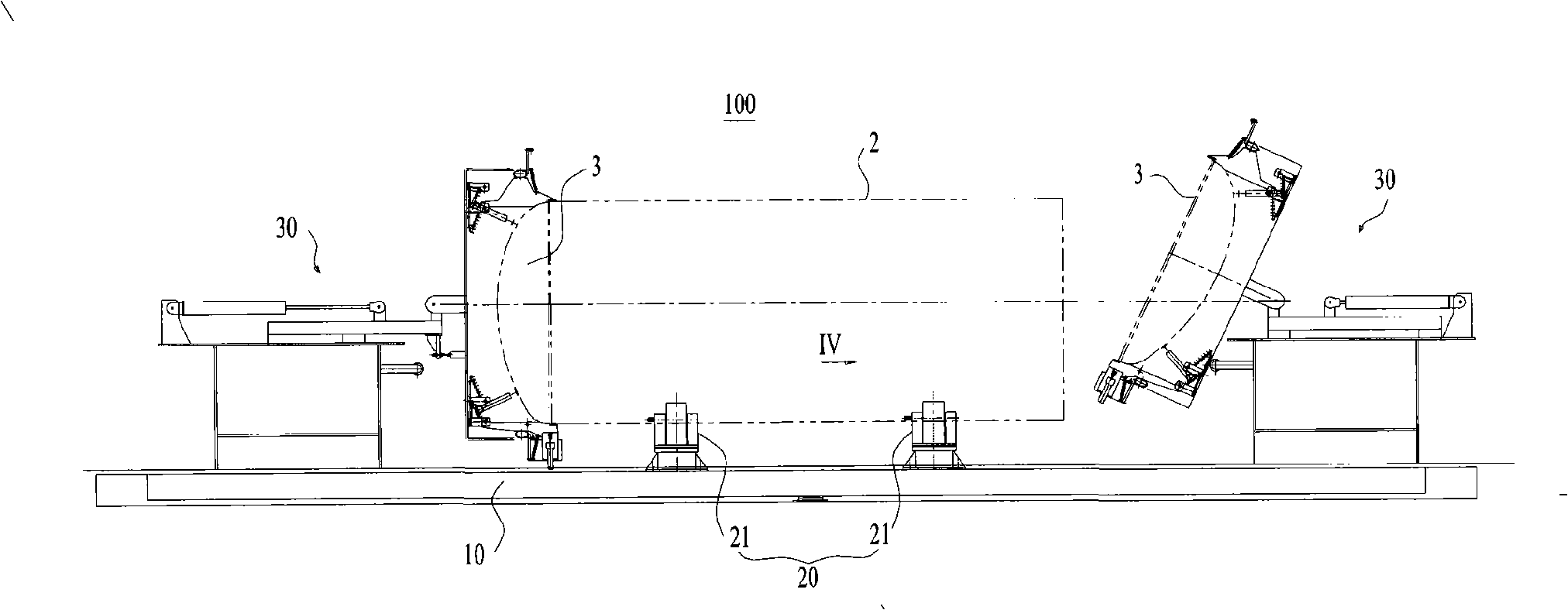

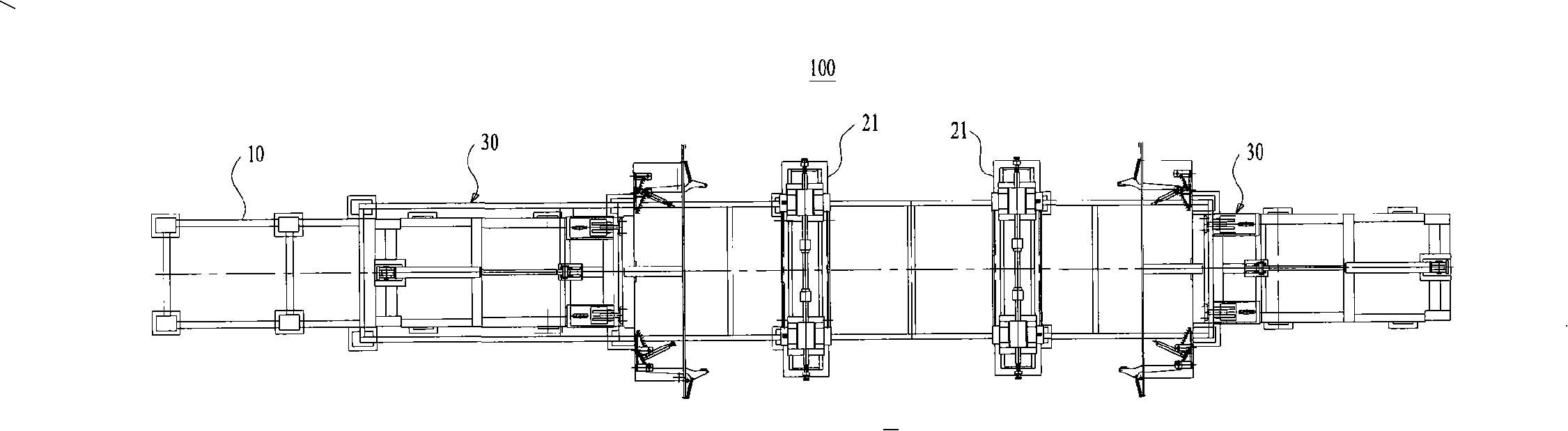

[0037] Figure 2 to Figure 9 Shown is an assembly stand 100 according to an embodiment of the present invention, which includes a chassis 10 set on the ground foundation, a roller frame 20 and two chuck assemblies 30 arranged on the chassis 10, wherein the two chucks The assemblies 30 are opposite to each other, and are used to hold the head 3 of the can container; and the roller frame 20 is located between the two chuck assemblies 30, and is used to place the cylinder body 2 of the can container. The roller frame 20 includes two idler rollers 21 spaced apart from each other. Such as Figure 4 As shown, the idler roller 21 includes a bracket 22 for fixing on the chassis 10 and two rollers 23 arranged on the bracket 22 . The cylinder body 2 of the tank container is placed on the rollers 23 . Preferably, in order to adapt to cylinders of different specifications, the distance between the two supporting rollers 21 can be adjusted according to actual needs to meet cylinders wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com