Method for continuously hoisting rolling mill housings by hydraulic pushing and lifting

A rolling mill archway, hydraulic lifting technology, applied in cranes, traveling mechanisms, transportation and packaging, etc., can solve the problems of insufficient crane lifting capacity, large lifting cost of hydraulic jacking and lifting, and long construction period, so as to save trouble, The lifting process is simple and the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

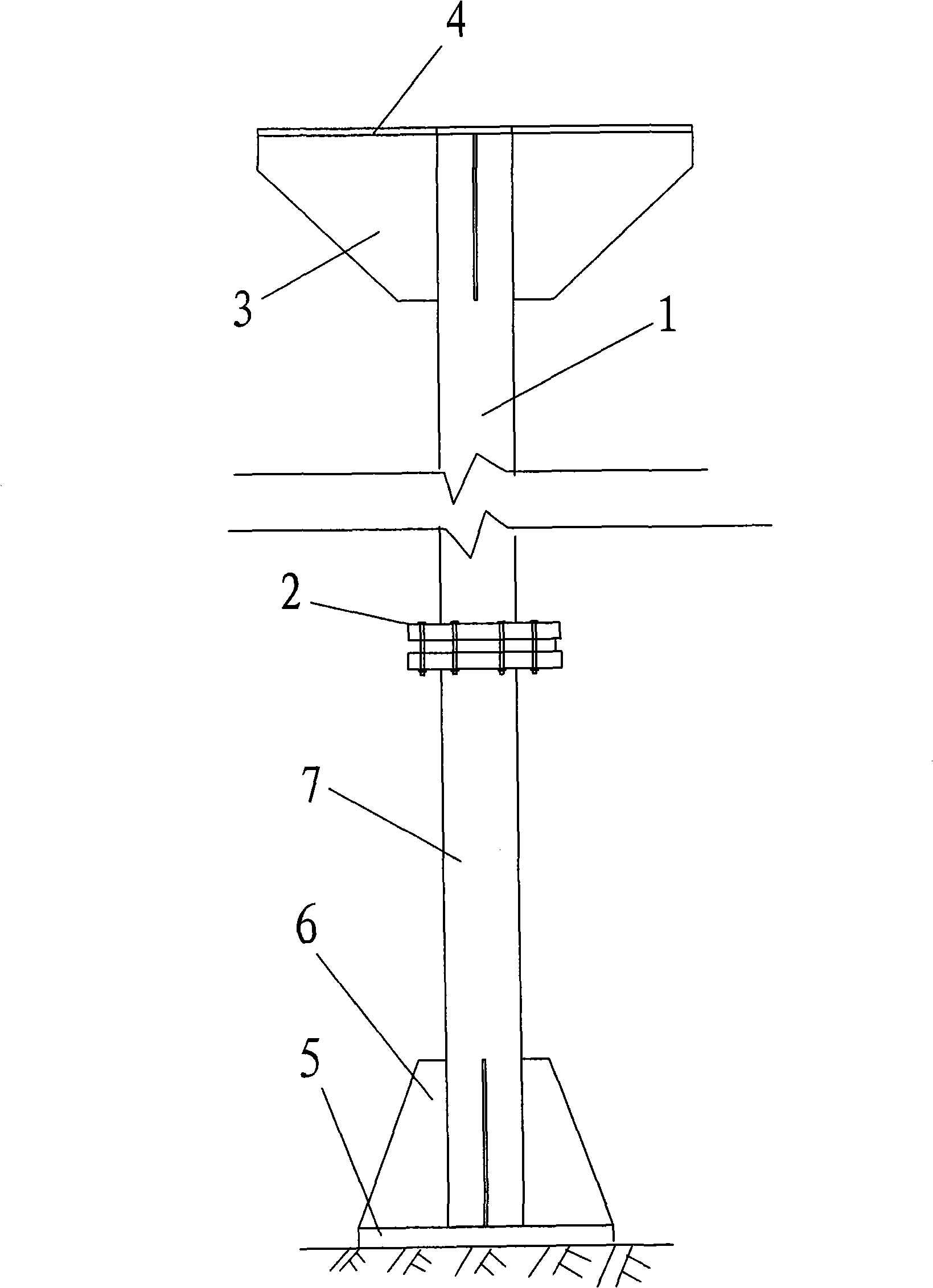

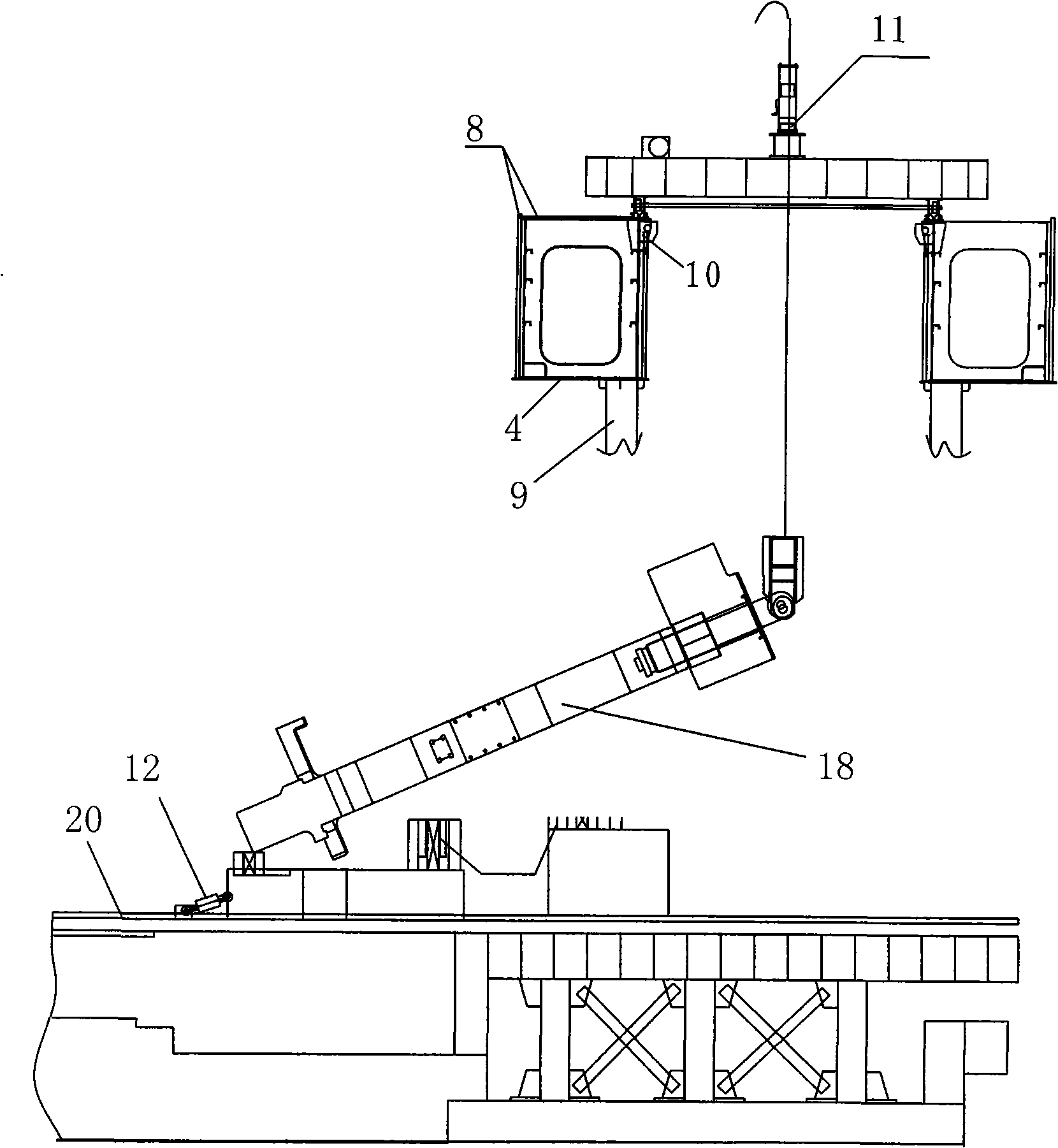

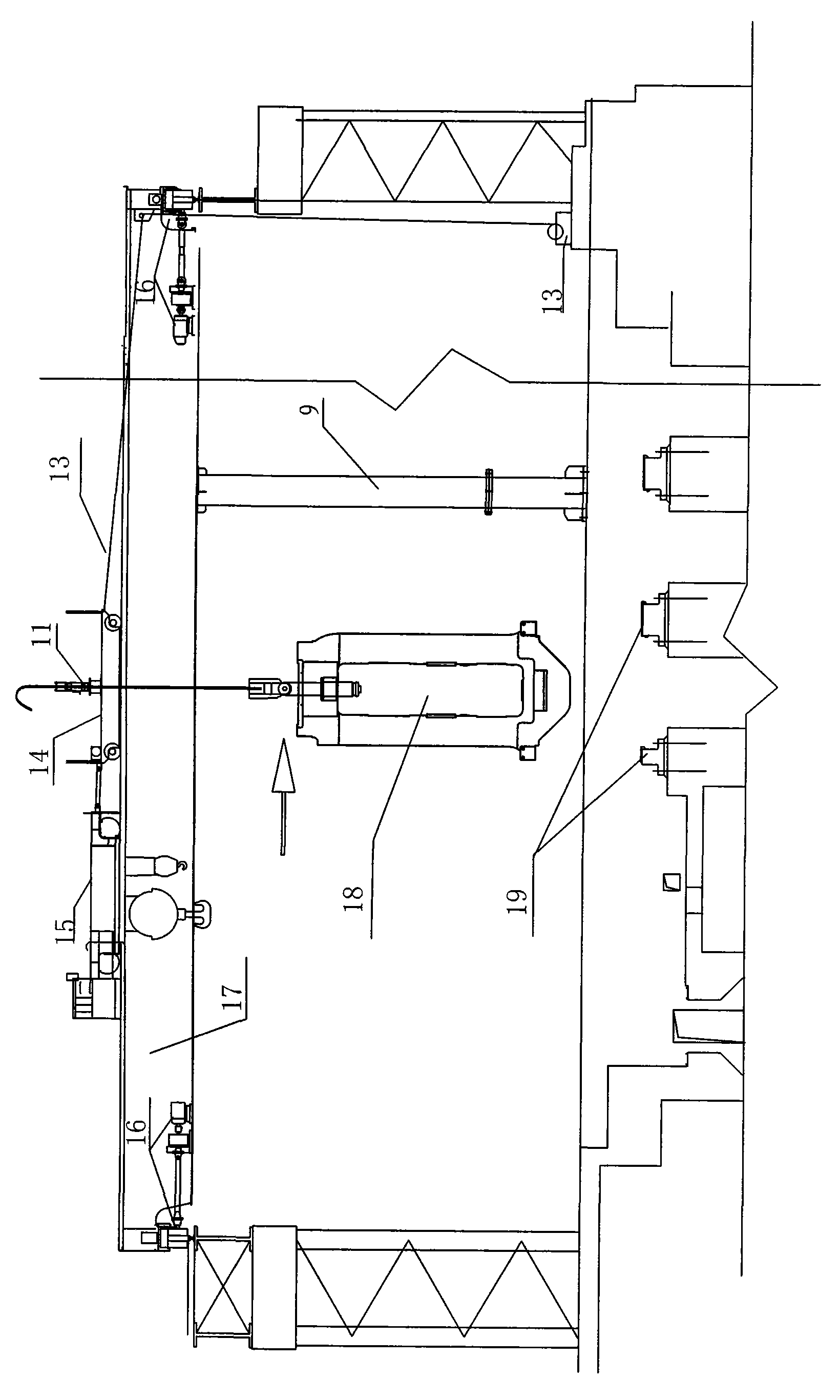

[0014] The method provided by the present invention for continuously hoisting and hoisting the rolling mill archway by means of hydraulic jacking is specifically as follows: use the crane as a platform, install a temporary trolley 14 with the same span as the trolley on the trolley, and then install the hydraulic hoist 11 on the trolley 14, and a movable support 9 is connected under the main beam of the vehicle to increase the load capacity of the main beam of the vehicle, and a set of hydraulic propeller 12 is arranged on the ground, and the archway 18 is hoisted by the hydraulic propeller 12 and the hydraulic hoist 11, and then The archway is hoisted to the installation position by driving, temporary trolley 14, hydraulic hoist 11, and winch 13, and the vertical and horizontal movements are free to realize the continuous hoisting and in-position work of multiple archways.

[0015] The specific steps of the method include:

[0016] (1) Disconnect the movable support 9 under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com