Integral duplex dual-polyline variable-amplitude winding drum of caterpillar crane

The technology of a crawler crane and a double drum is applied in the direction of the crane, the hoisting device, the mechanism of the clockwork, etc., which can solve the problems of wear, rope disorder, and extrusion of the steel rope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

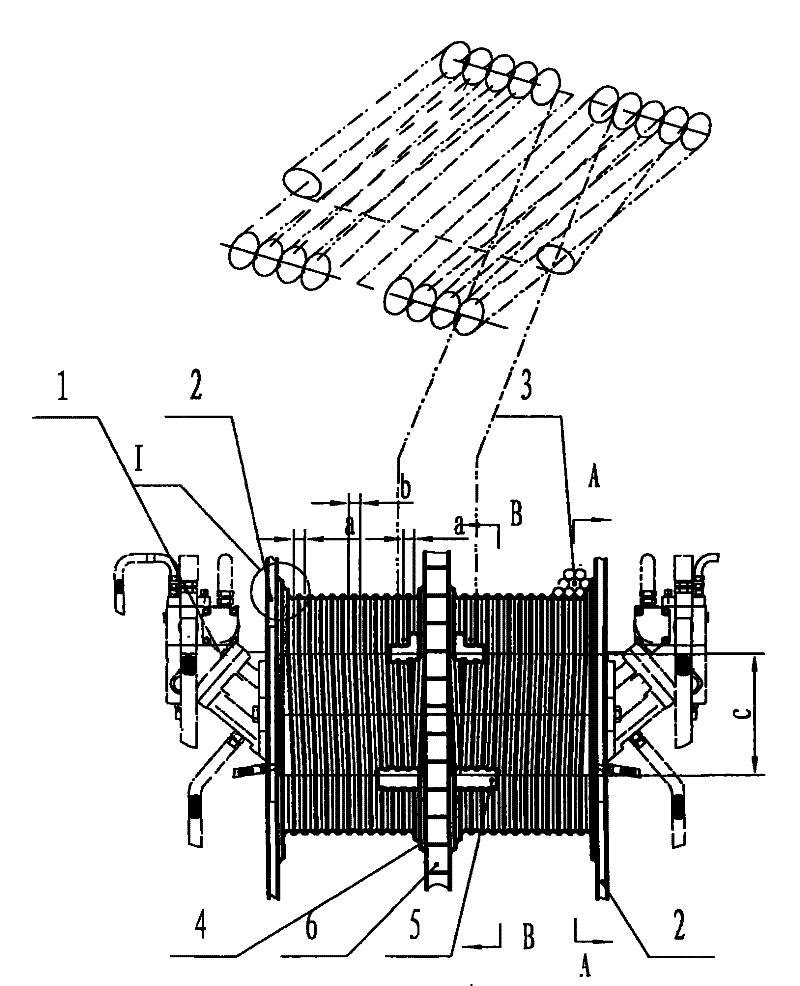

[0012] figure 1 The solid line in the figure shows the structure of the luffing drum, the upper part of which is the steel rope working system on the luffing mast, and the double-dotted lines on both sides are driven by synchronously driven motors Device 1, the reducer of the motor drive device 1 is placed inside its reel.

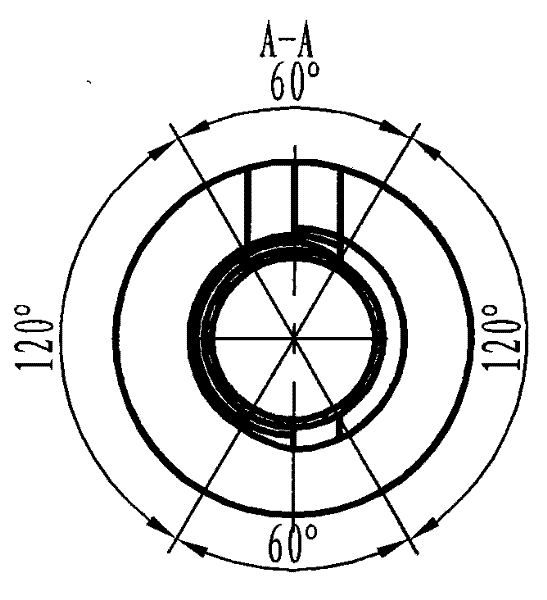

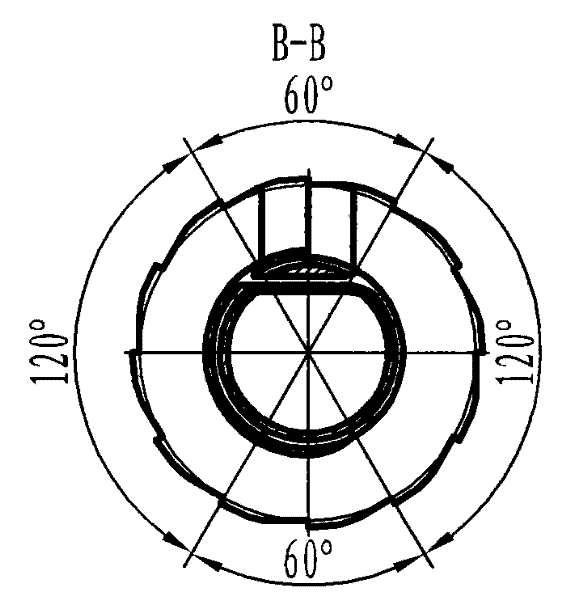

[0013] Such as Figures 1 to 4 As shown, the luffing reel of the present invention adopts an integrally cast double reel structure, that is, it is cast as a whole. The double drums are left and right symmetrically designed, bounded by the middle baffle 6, the rotation of the rope grooves is opposite to the left and right, and the rope outlets 5 are symmetrically distributed on both sides of the middle baffle 6. The rope arrangement rope groove of the luffing drum adopts a double broken line rope groove structure. Two sections of broken line rope grooves with an angle range of 60° are symmetrically arranged on the circumference of the rope groove, and eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com