Fine clarifying method of electric melting furnace and device

A clarification device and electric melting furnace technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve problems such as difficulty in discharging glass liquid gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

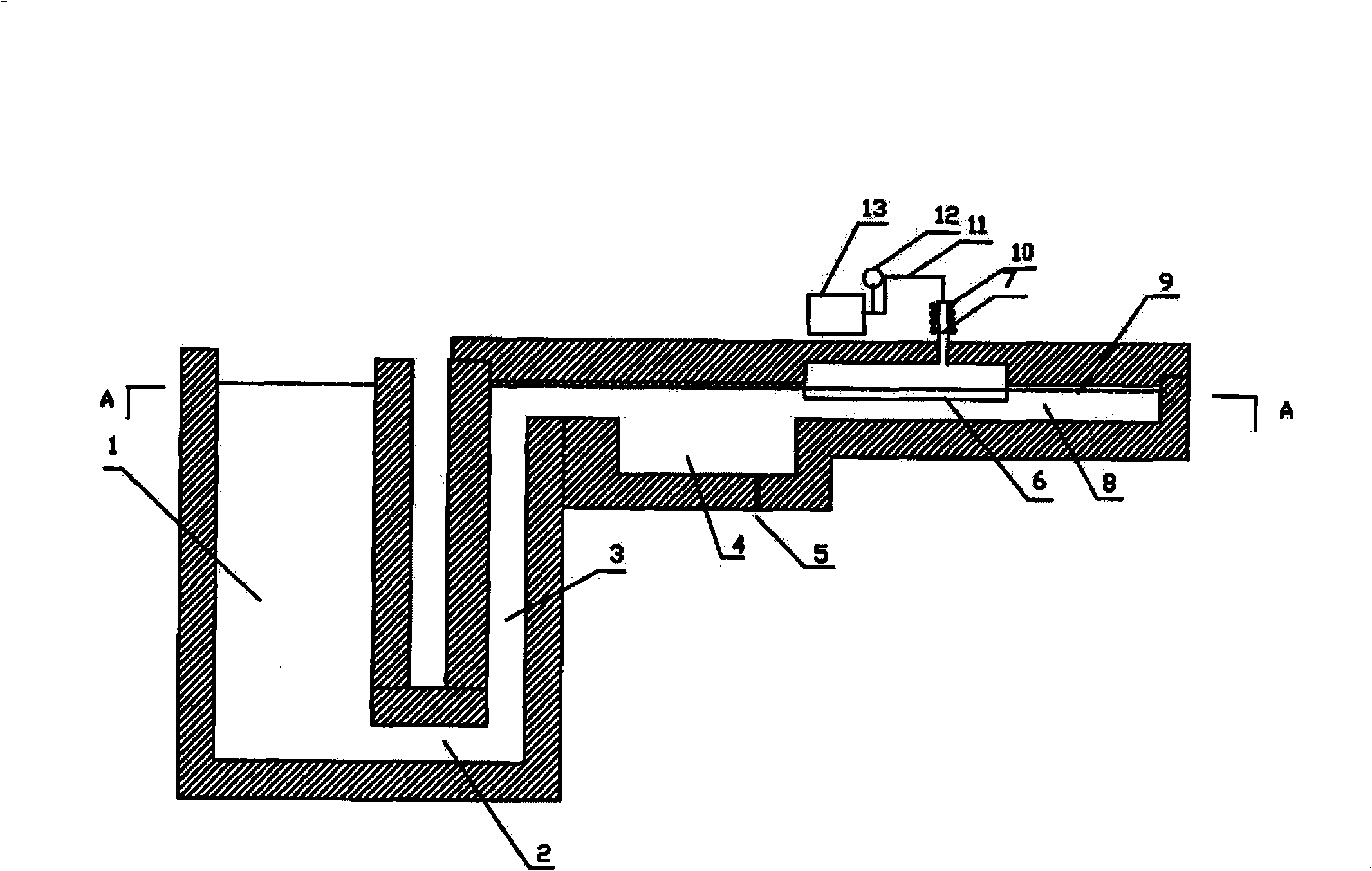

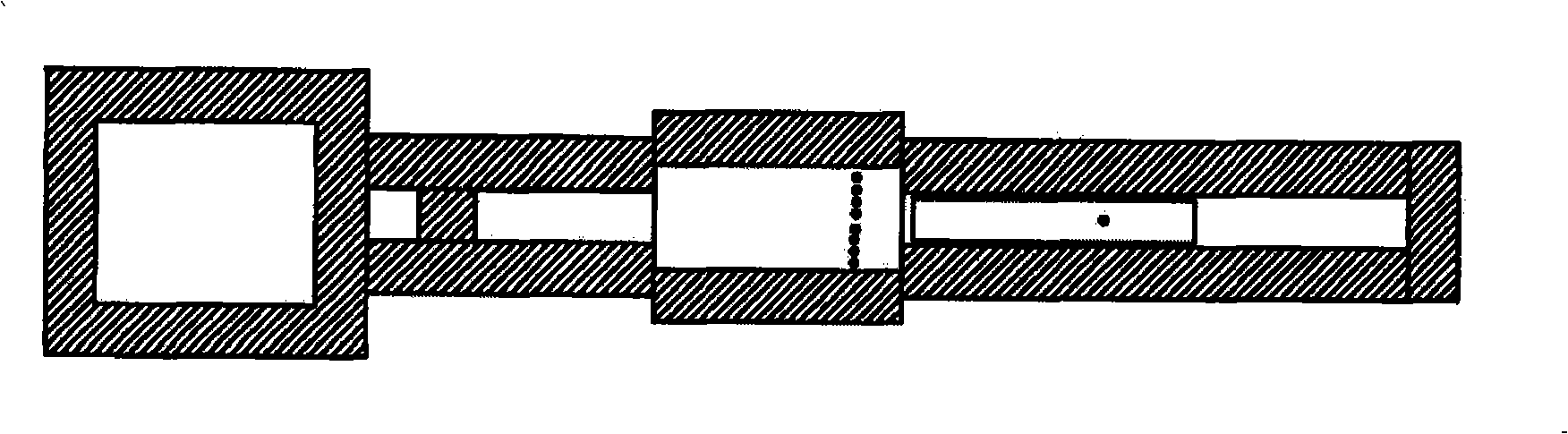

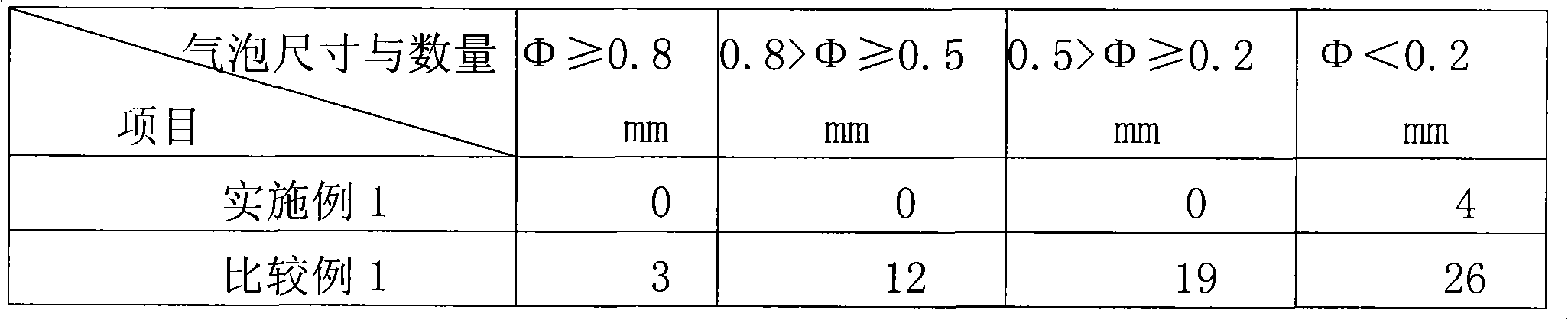

[0036] First, melt the aluminosilicate glass (glass chemical composition wt%) with 17% alumina in the melting pool of the electric melting furnace: SiO 2 60.2, Al 2 O 3 17.3, CaO 0.5, MgO 4.0, Na 2 O 14.5, K 2 O 3.5, the highest temperature of the molten glass in the melting tank reaches 1640℃, and then enters the clarification tank through the flow hole and ascending channel. The clarification tank area is 35% of the melting tank area, the depth of the tank is 600mm, and the width of the clarification tank is the width of the feeding channel. 2 times, two rows of bottom molybdenum electrodes are used for power supply at the front of the clarification tank, and the glass viscosity is 10 2.5 dPa·s (temperature 1560℃), install a row of bubble tubes at the bottom of the clarification tank near two-thirds of the clarification tank, use pulse bubbling to control the bubbles passing into the glass liquid, and the glass liquid clarified by the clarification tank Enter the platinum decomp...

Embodiment 2

[0040] First, melt the Pyrex borosilicate glass (glass chemical composition wt%) containing 12.5% boron oxide in the melting pool of the electric melting furnace: SiO 2 80.5, Al 2 O 3 2.5, B 2 O 3 12.5, Na 2 O 4.5, the maximum temperature of the molten glass in the melting tank reaches 1680℃, and then enters the clarification tank through the flow hole and ascending channel. The clarification tank area is 20% of the melting tank area, the depth of the tank is 300mm, and the width of the clarification tank is the width of the feeding channel. 3 times, two rows of bottom molybdenum electrodes are used for power supply at the front of the clarification tank, and the glass viscosity is 10 2.8 dPa·s (temperature 1590℃), install a row of bubble tubes at the bottom of the clarification tank close to two-thirds of the clarification tank, and use continuous bubbling to control the bubbles that pass into the glass liquid. The glass liquid clarified by the clarification tank Enter into the...

Embodiment 3

[0044] First, melt low-alkali glass fiber (glass chemical composition wt%): SiO 2 73.5, Al 2 O 3 0.5, B 2 O 3 22.5, Na 2 O 2.0, MgO 0.5, the highest temperature of the molten glass in the melting tank reaches 1540℃, and then enters the clarification tank through the flow hole and ascending channel. The area of the clarification tank is 50% of the area of the melting tank, the depth of the tank is 800mm, and the width of the clarification tank is the feed 1.5 times the width of the channel, two rows of bottom molybdenum electrodes are used for power supply at the front of the clarifier, and the glass viscosity is 10 2.8 dPa·s (temperature 1460℃), install two rows of bubble tubes at the bottom of the clarification tank near two-thirds of the clarification tank, and use a continuous method to control the bubbles that pass into the glass liquid, and the glass liquid clarified by the clarification tank enters the supply In the platinum decompression hood of the forehearth, an exhau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com