Consolidated grouting method for anchoring cement of bedrock contact segment

A technology of consolidation grouting and cement grouting, which is applied in the direction of basic structure engineering, construction, etc., can solve the problems of increasing project investment in the overall construction progress, increasing the amount of cement consolidation grouting concrete drilling, etc., to reduce the amount of drilling engineering, The effect of reducing input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

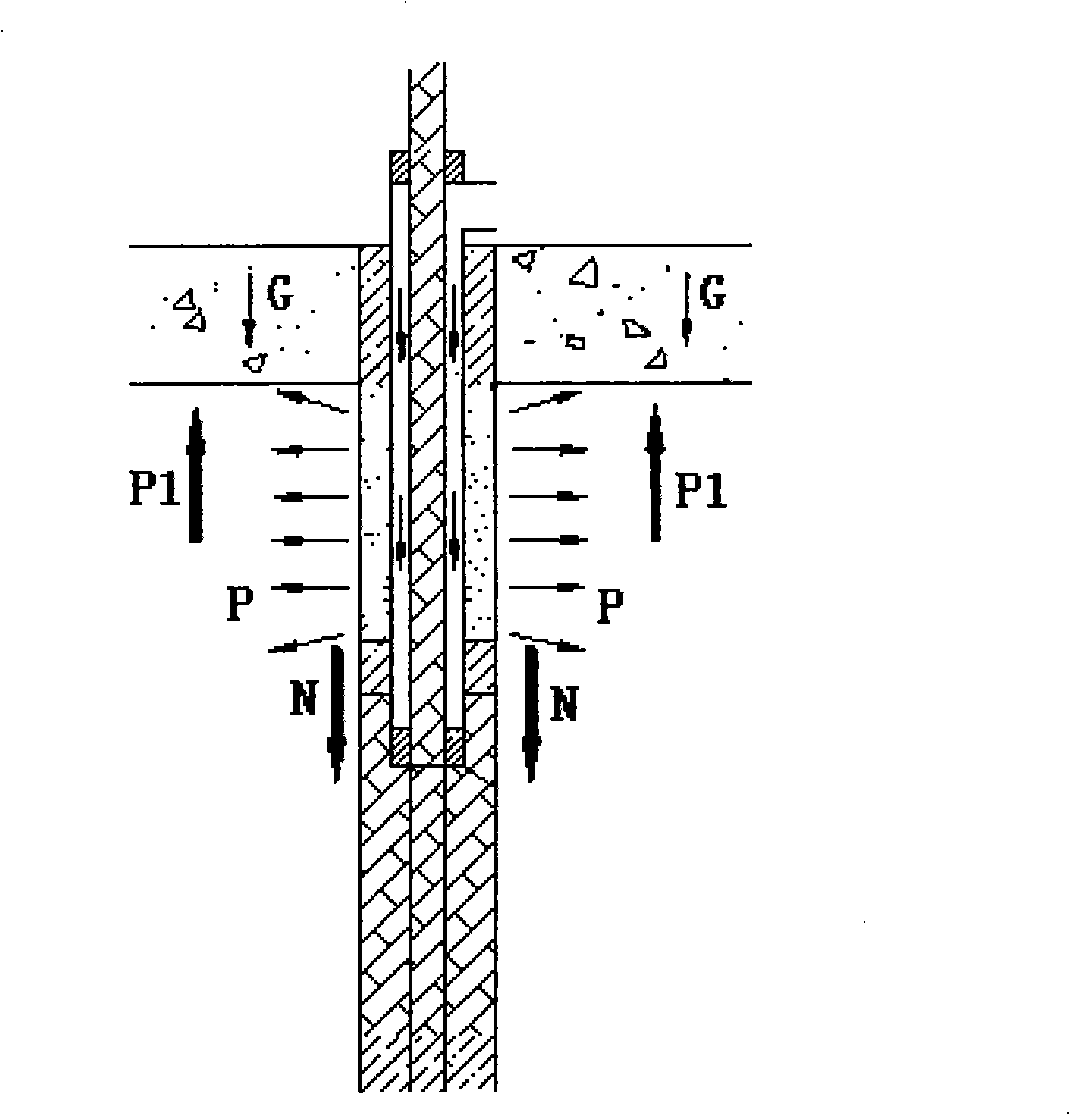

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

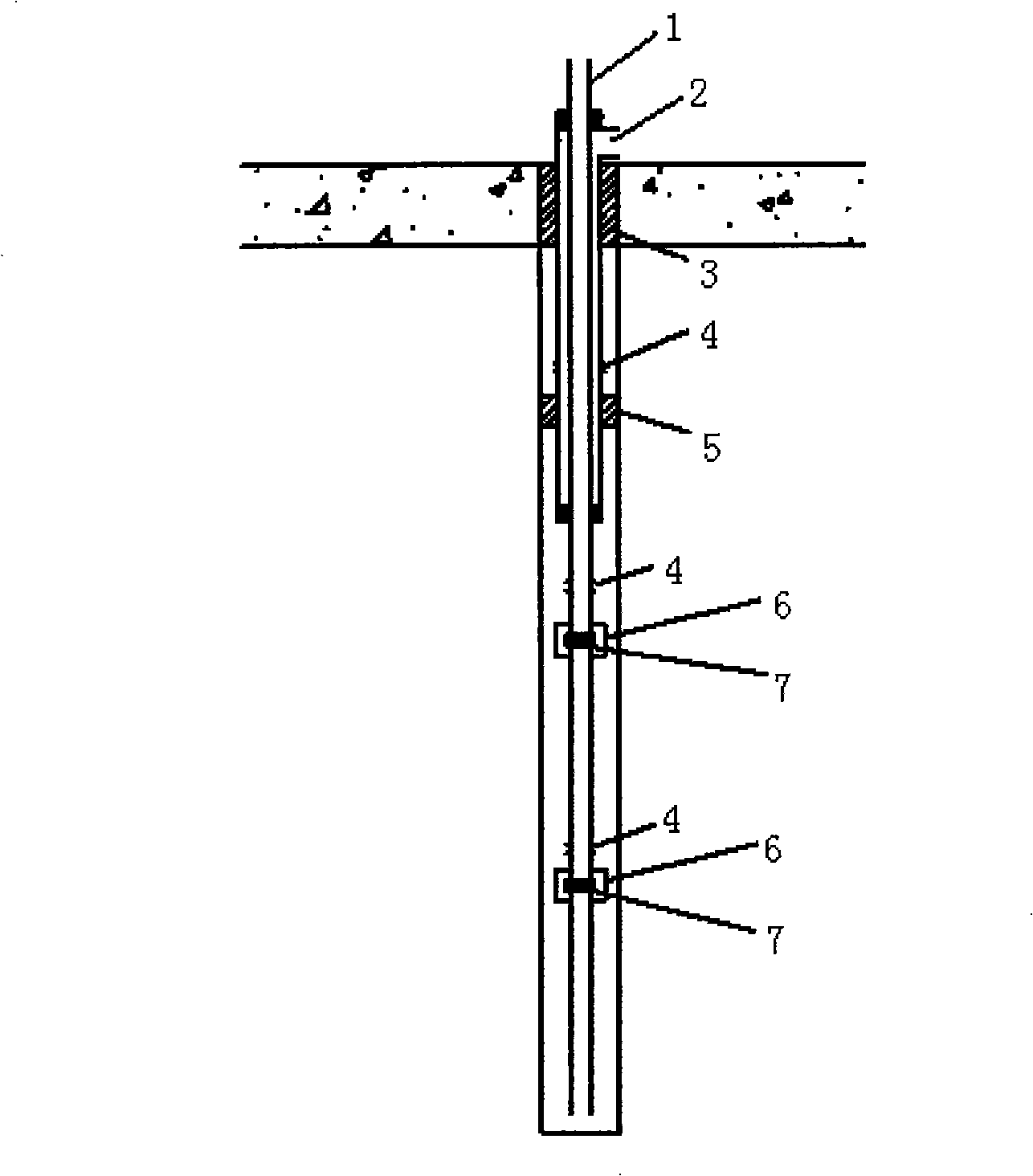

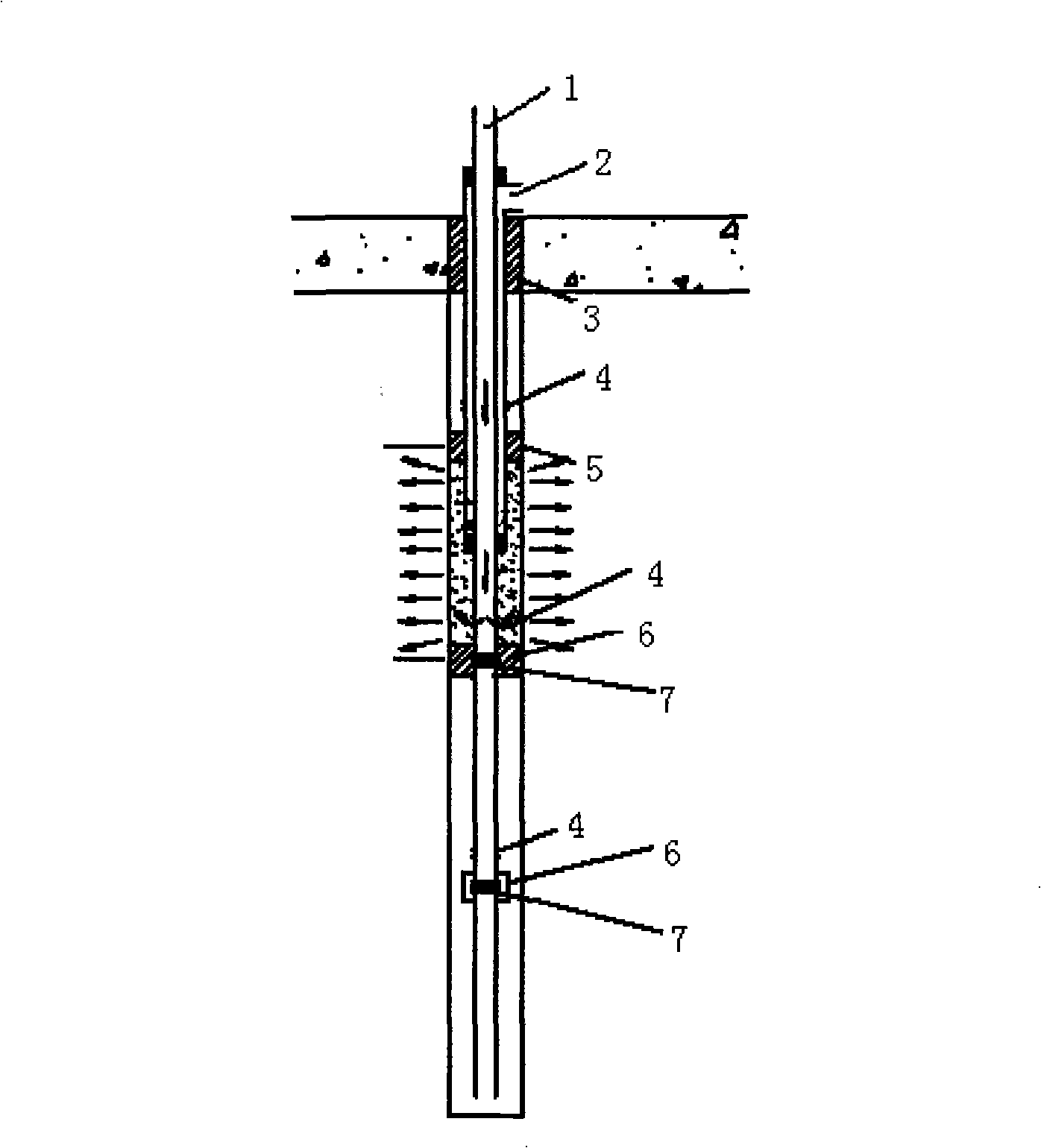

[0014] (1) After the drilling rig drills through the concrete cover plate of the contact surface, one grouting hole is completed at a time.

[0015] (2) According to the segmental requirements of grouting, the process of segmental grouting from top to bottom, install the combined grouting steel pipe, fine sand bag grouting divider and filter bag type grouting segmental packer in segments, and use water filter The grouting anchoring method is to anchor the combined grouting steel pipe on the concrete weight cover plate. The combined grouting steel pipe used here is a thicker steel pipe, preferably a 2-inch pipe covering a thinner steel pipe, preferably a 1-inch steel pipe. The length of the 2-inch pipe is from the grouting hole to the contact section beyond the bedrock (the first section from the bottom of the hole is the bedrock contact section), and the device for anchoring the combined grout pipe to the concrete slab simultaneously The role of grout blocking. Install the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com