Gas control valve device of revolution film type fuel gas meter

A membrane gas meter and gas valve technology, which is applied to valve devices, sliding valves, valve details, etc., can solve the problems of increasing the pressure loss of the gas meter, affecting the measurement accuracy of the gas meter, and occupying the cross-sectional area of the gas channel. Small cross-sectional area, low manufacturing process difficulty, and reduced pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

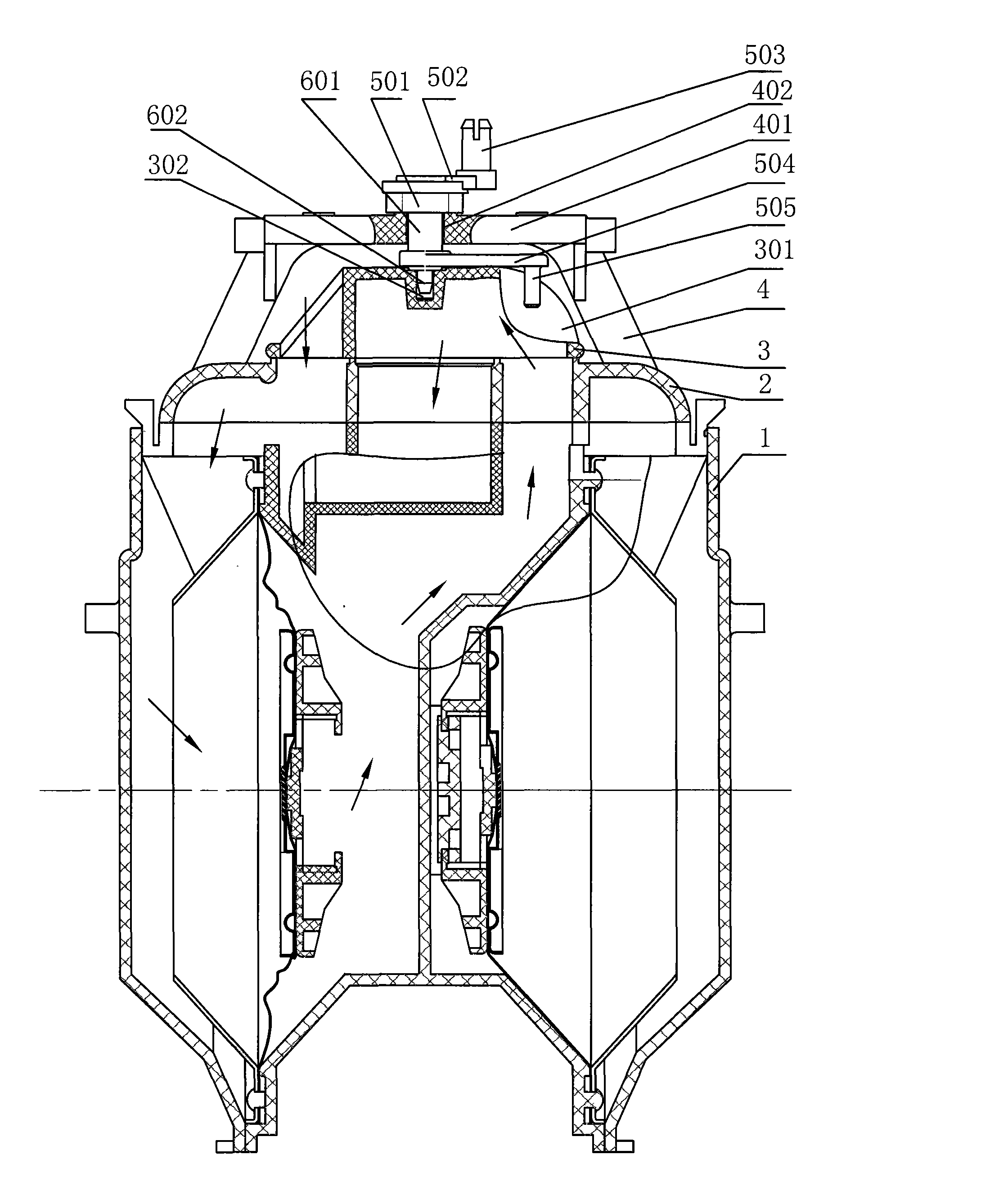

[0011] As shown in the drawings, a gas control valve device for a rotary membrane gas meter includes a valve seat 2 . The valve seat 2 is sealed and fixed on the top of the core housing 1 by a sealant.

[0012] The present invention also includes a valve cover 3 . As shown in the drawings, the valve cover 3 is rotatably fitted on the valve seat 2, and there is a flat sealing surface between the valve cover 3 and the valve seat 2. In the accompanying drawings, the upper end surface of the valve cover 2 is formed with a positioning counterbore 302 that does not penetrate the end surface of the valve cover, and a shifting groove 301 is formed on the side end surface of the valve cover 2 .

[0013] The present invention also includes a gear bracket 4 . The gear bracket 4 is fixedly assembled on the core housing 1 by fixing screws. As shown in the drawings, the upper frame body 401 of the gear bracket 1 is located above the valve cover 3 , and a positioning through hole 402 is o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap