Wiring detection system and wiring detection method

A detection system and wiring technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as large detection and repair costs, reduce tooling renovation costs, save education and training costs, and reduce wiring errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

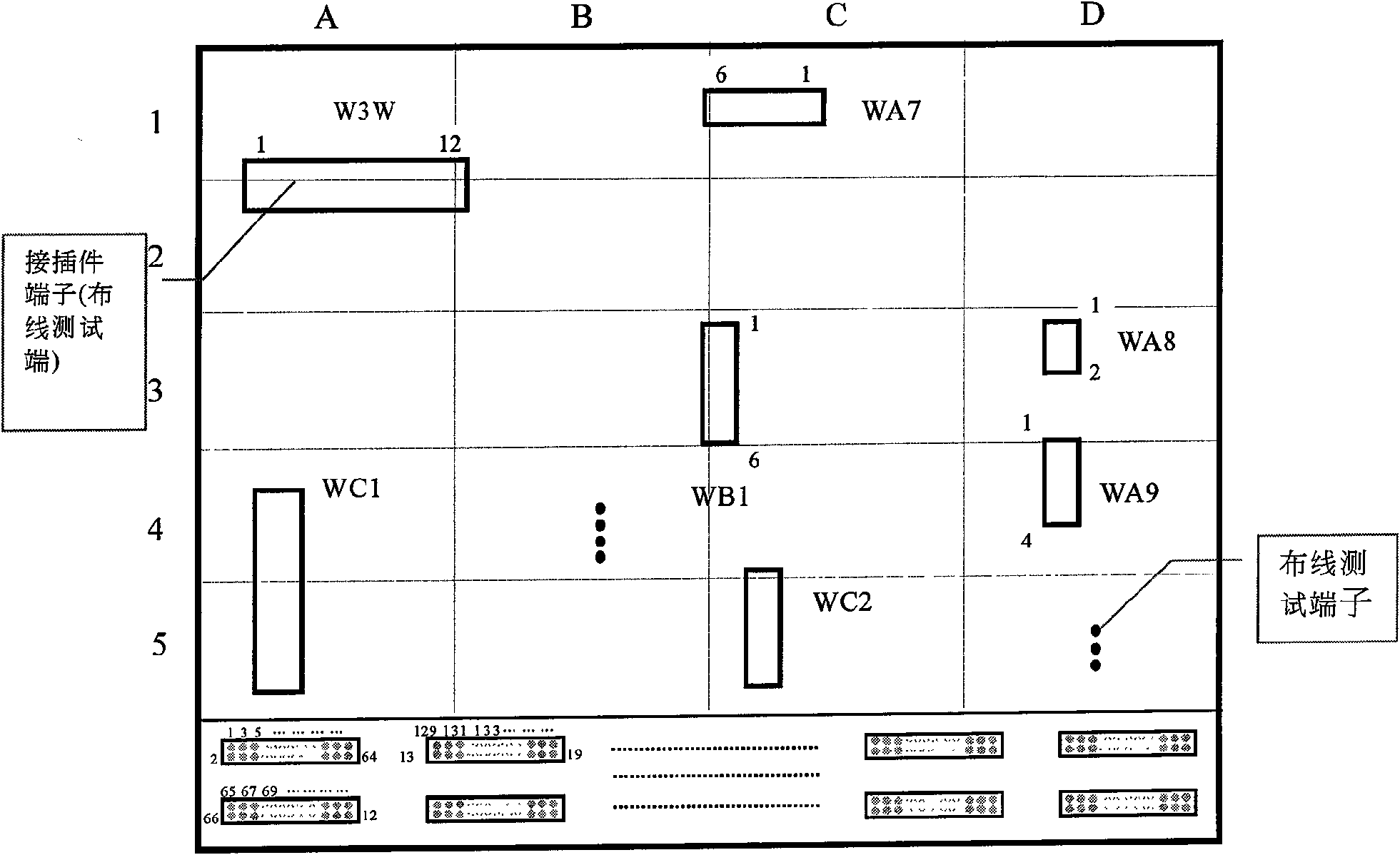

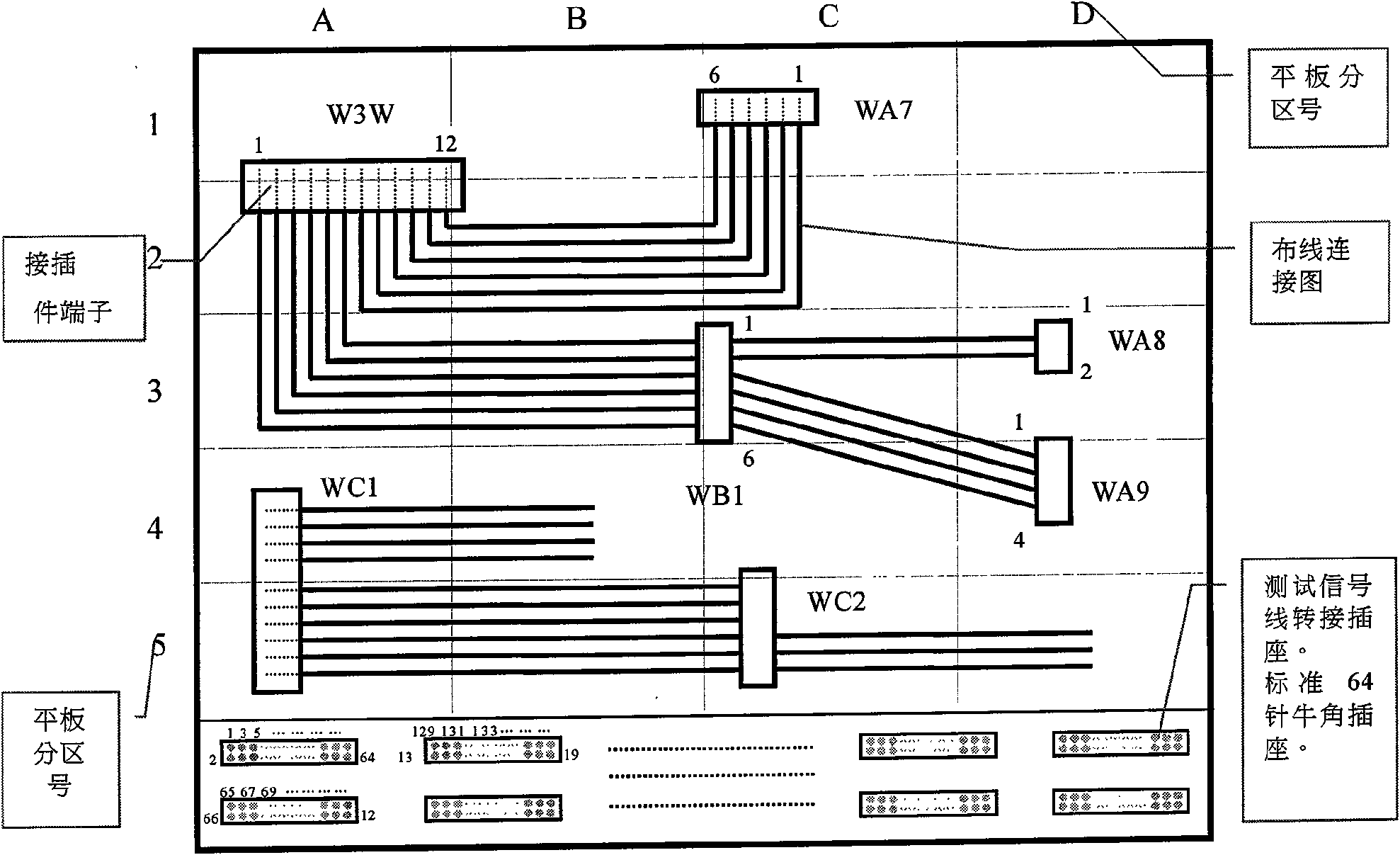

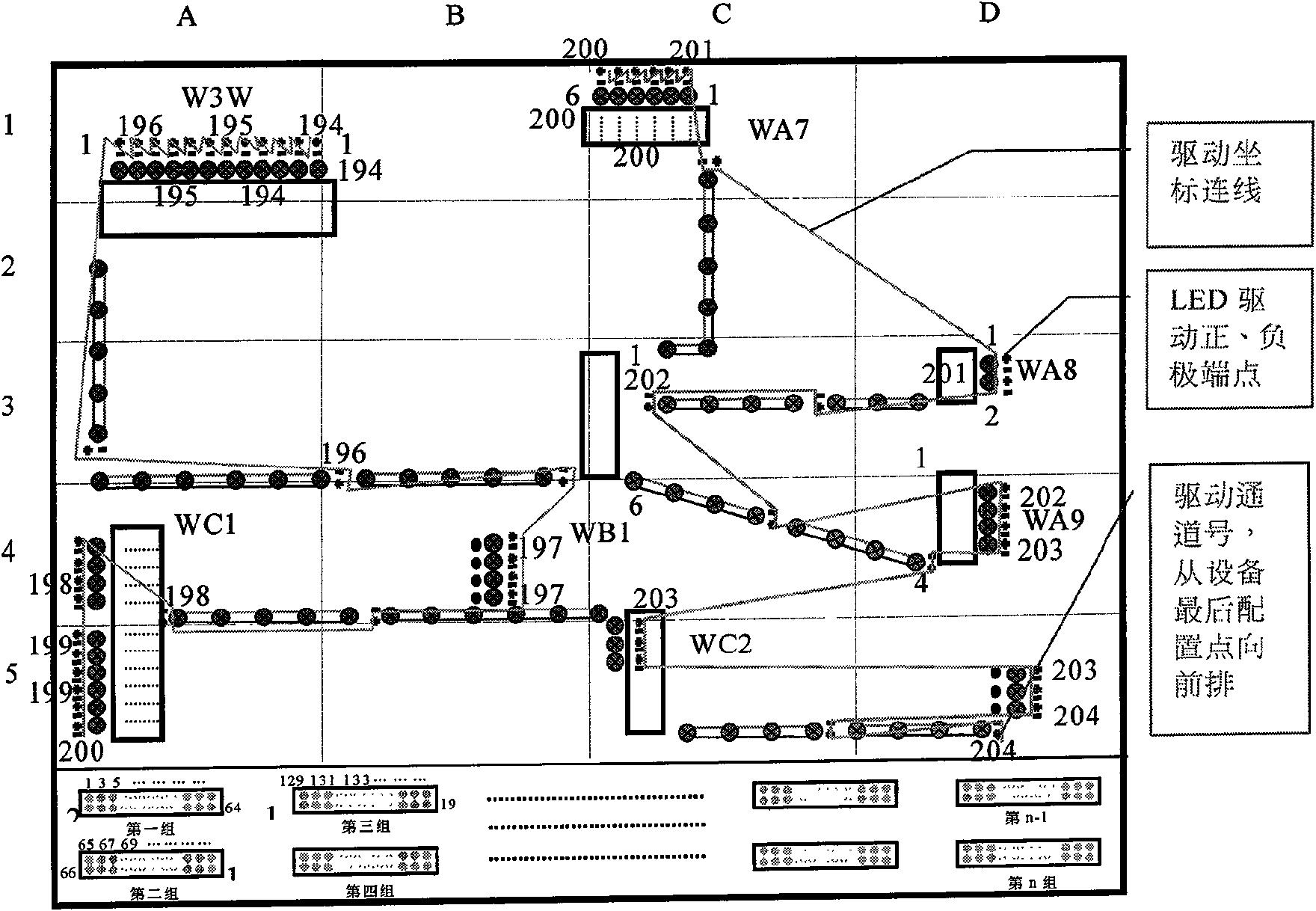

[0018] see Figure 5 , the wiring detection system of the present invention includes a single-chip computer serially connected to a computer, and the single-chip computer and the main computer exchange commands and data through serial communication, and adopt A / D converter multi-way cards and MAX232 to realize the connection between RS232 and TTL levels. mutual conversion. SCM circuit I / O line, used to connect with the analog wiring board. The single-chip microcomputer is connected with an address latch and a data bus driver, and the address latch is connected with a gate circuit and a decoder, and the system uses the decoder to perform address decoding and is used for gating each chip latch. The data bus needs to add a bus driver to increase the load capacity of the bus. Gate circuits, decoders and data bus drivers are connected to wiring boards through bidirectional data latches. Because a connection point can be both a starting node and an ending node, the I / O line shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com