Metal pigment composition

一种金属颜料、组合物的技术,应用在颜料浆料、无机颜料处理、染色低分子有机化合物处理等方向,能够解决金属颜料色调的降低等问题,达到遮盖力以及闪烁感优异、良好涂料贮藏稳定性和亮度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

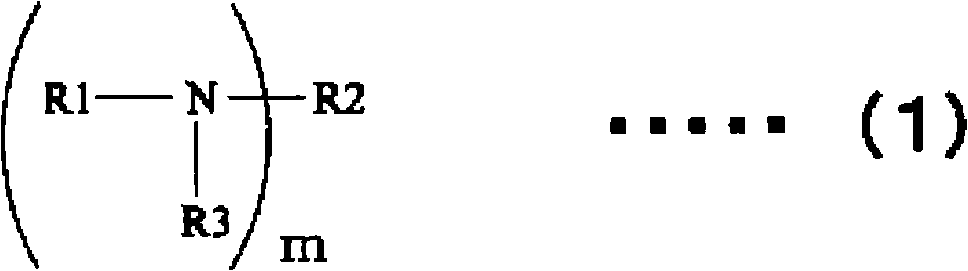

Method used

Image

Examples

Embodiment 1

[0057] In 135 g of a commercially available aluminum paste (Asahi Kasei Chemical Co., Ltd., trade name "GX-3100 (average particle size 10.5 μm, non-volatile content 74%)"), add 0.2 parts by weight to 100 parts by weight of flake aluminum powder Phosphotungstomolybdic acid (W=6, Mo=6) dimethylethanolamine salt was kneaded at 60° C. for 48 hours.

Embodiment 2

[0059] In 135 g of a commercially available aluminum paste (Asahi Kasei Chemical Co., Ltd., trade name "GX-3100 (average particle size 10.5 μm, non-volatile content 74%)"), add 0.5 parts by weight to 100 parts by weight of flake aluminum powder Triethanolamine phosphotungstic acid was kneaded at 90°C for 24 hours.

Embodiment 3

[0061] Add 232 g of propylene glycol monomethyl ether to 68 g of commercially available aluminum paste (Asahi Kasei Chemical Co., Ltd., trade name "GX-3100 (average particle size: 10.5 μm, non-volatile content: 74%)") to obtain a slurry concentration of 16.7%. In this slurry, 1.6 parts by weight of dioctylamine phosphomolybdate was added to 100 parts by weight of flake aluminum powder, and stirred at 40° C. for 5 hours. Thereafter, the slurry was filtered to obtain an aluminum pigment composition having a nonvolatile content of 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com