Blade arrangement

A technology of blades and damping elements, applied in the directions of supporting elements of blades, preventing leakage, and other chemical processes, etc., can solve the problems of reducing the vibration load of blade devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

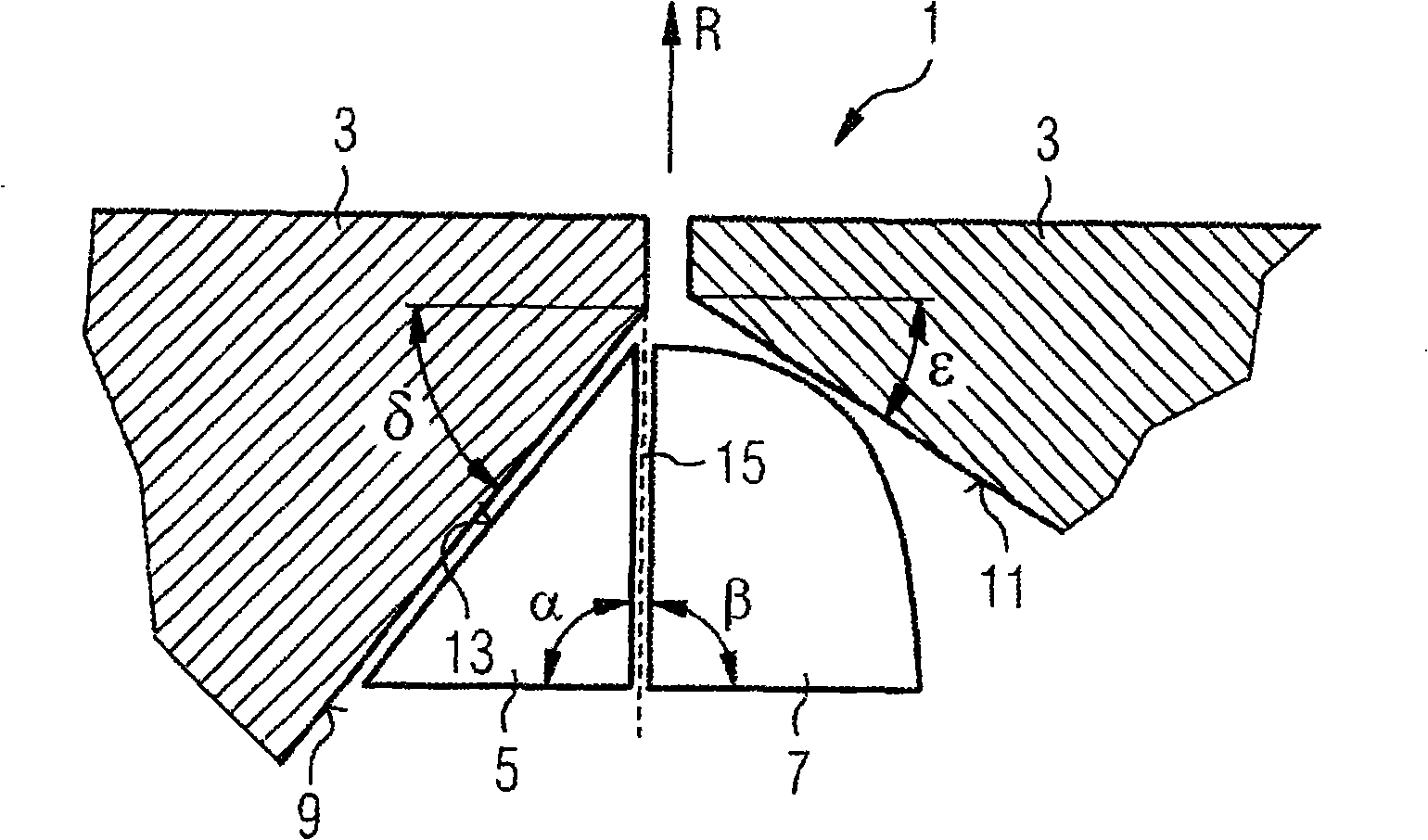

[0016] figure 1 A schematic sectional view of a blade arrangement 1 according to the invention is shown in a section perpendicular to the rotor axis. This sectional view shows two blade platforms 3 of adjacent blades of a blade arrangement 1 according to the invention. The blades are suspended on the rotor disk of the blade arrangement 1 and have a small distance from one another. Two damping elements 5 , 7 are loosely arranged between the two blade platforms 3 . The two damping elements 5 , 7 form a damper group and are axially configured as rods, wherein the damping element 7 has a quarter-circular cross section and the damper 5 has a wedge-shaped cross section.

[0017] The undersides of the two blade platforms 3 form friction surfaces 9 , 11 . The two damping elements 5 , 7 are pressed against said friction surfaces 9 , 11 as a result of centrifugal force when the rotor (not shown) rotates. The friction surfaces 9, 11 now form specific angles δ and ε with the plane for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com