Duct hydraulic-bend forming machine

A forming machine and hydraulic technology, which is applied in the production of gas pipe connecting elbows and elbow forming machines, can solve the problems of poor forming quality and low single-station efficiency, and achieve good forming quality, stable transmission and stable process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

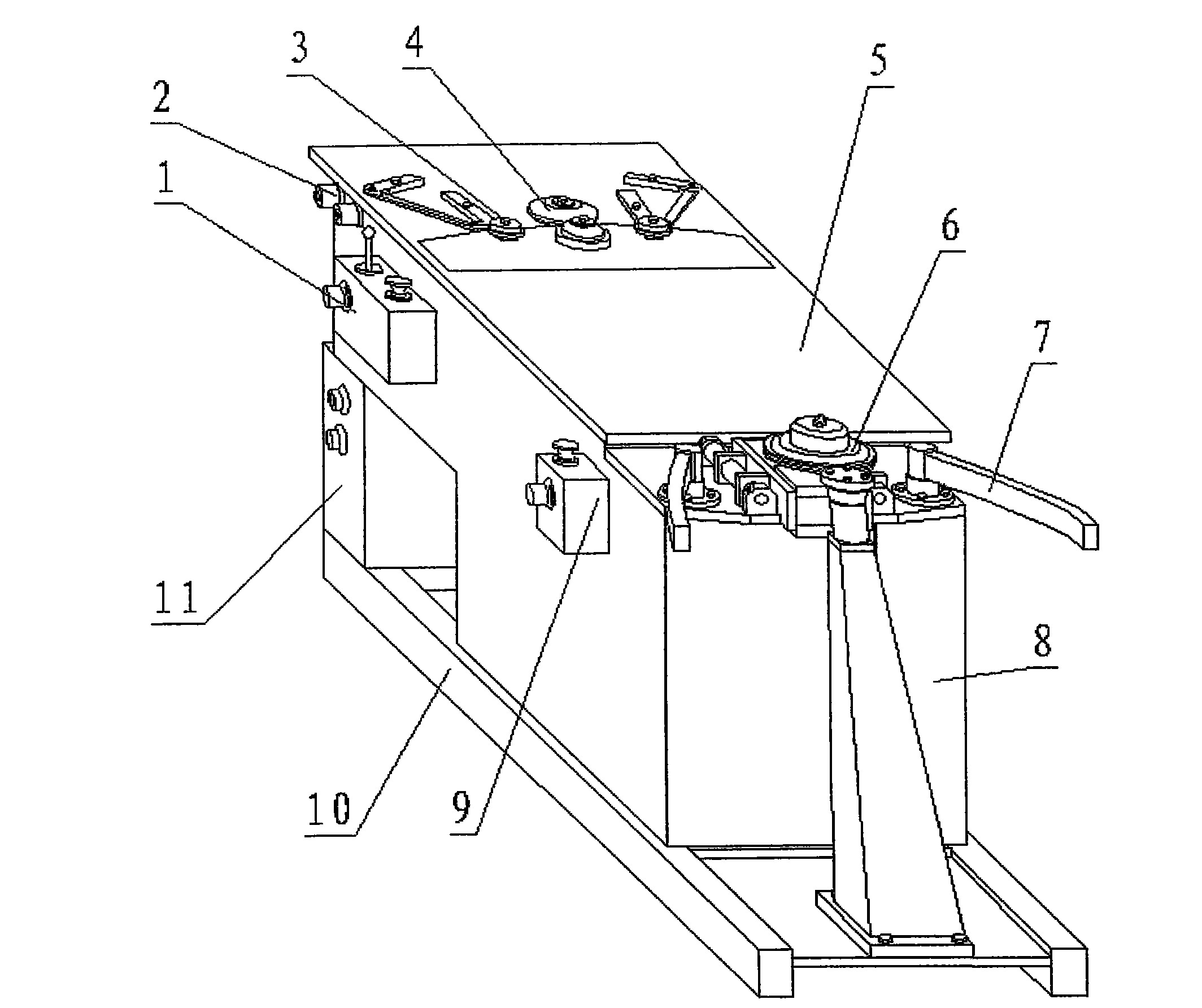

[0026] see figure 1 , the air duct hydraulic elbow forming machine of the present invention mainly consists of a frame 10, a box body 8, a working table 5, a table lifting mechanism 2, a flanging mechanism 4, a flanging press wheel mechanism 3, a forming engagement mechanism 6, and a forming bracket 7. The flanging control electric box 1, the forming control electric box 9 and the host electric control system 11 are composed. Described box body 8 is installed on the frame 10, and work table top 5 is installed on the box body 8 by table top elevating mechanism 2, and flanging mechanism 4 is installed in the middle of work table top 5, and flanging press wheel mechanism 3 has two pieces, is installed on On the worktable 5 on the left and right sides of the flanging mechanism 4, the forming engagement mechanism 6 is installed on the box body 8 and the frame 10, and placed on the side of the worktable 5, and the forming bracket 7 has two pieces, which are installed on the forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com