Method for half-breadth double-span total assembling and building in shipbuilding

A half-width type, ship technology, applied in ship construction, ship parts, ships, etc., can solve the problems of heavy workload of cross-section joints, affecting the progress of structural submission, unfavorable structural integrity of cabins, etc., to speed up the submission progress, The effect of reducing hull welding deformation and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

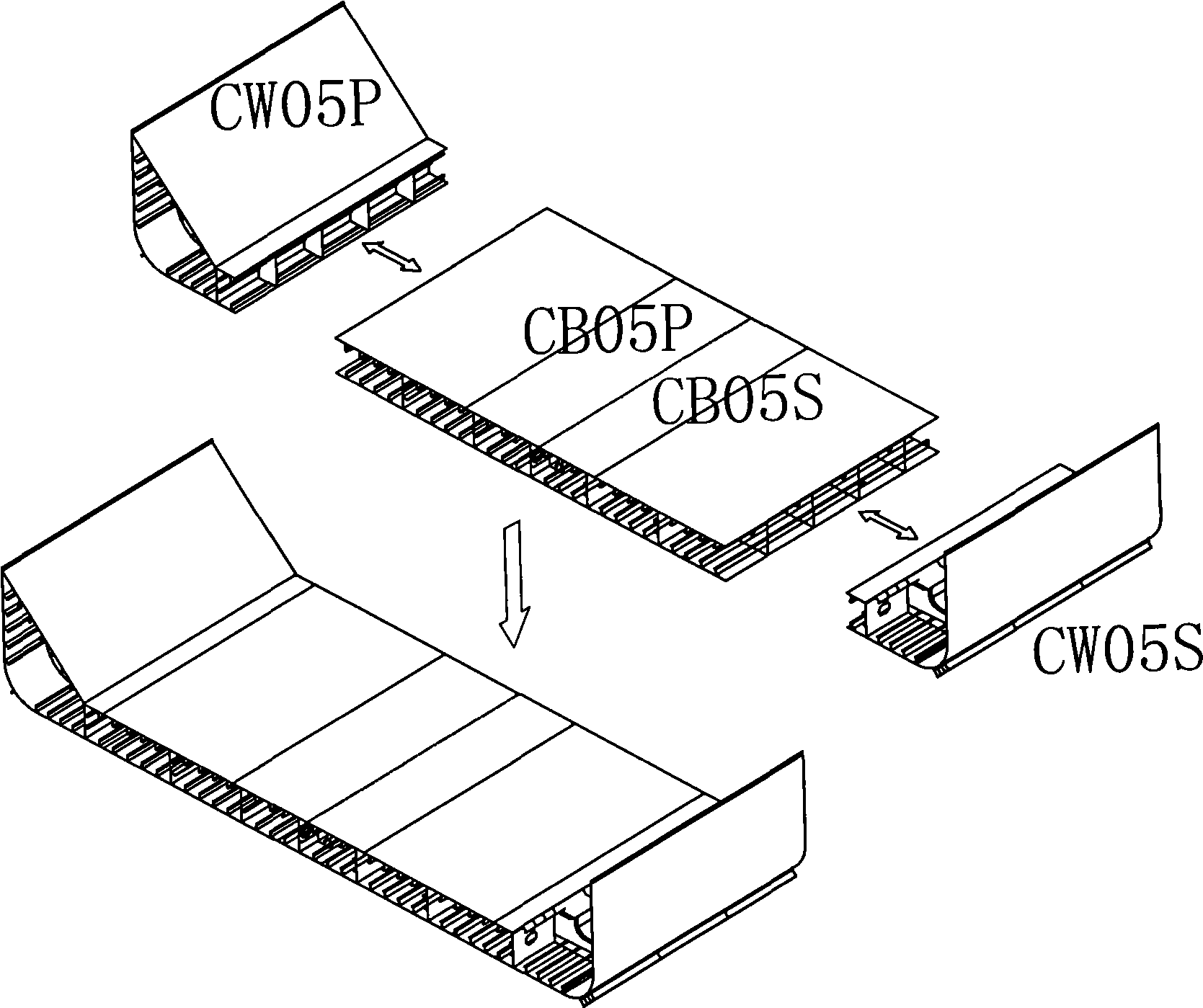

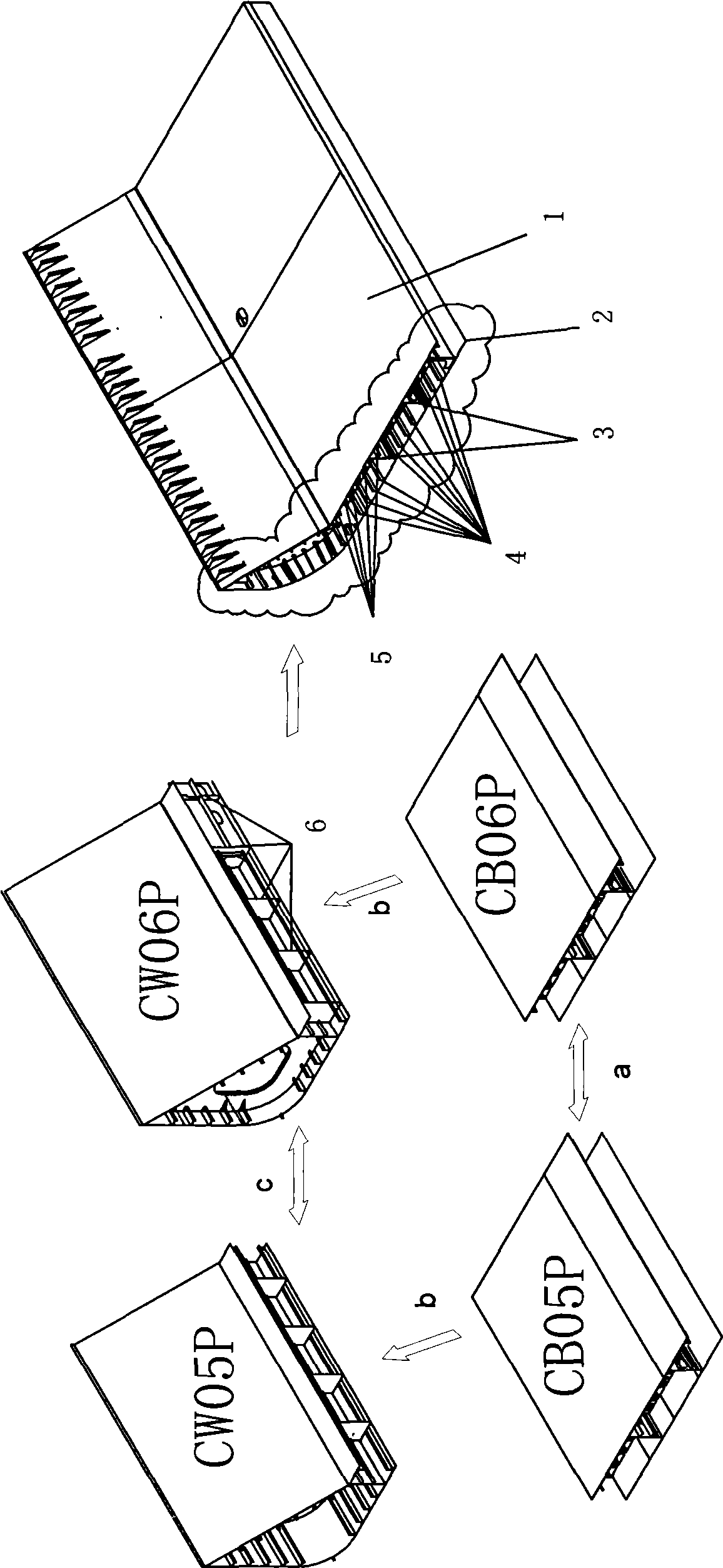

[0029] We use the general group of cargo compartment sections CB05, CB06, CW05, and CW06 sections of a 75000T class bulk carrier to illustrate the practical use.

[0030] Firstly, the CB05P segment and the CB06P segment are respectively positioned on the general group platform, and then the butt welding is carried out, mainly for the butt joint of the outer plate longitudinal, the inner bottom plate longitudinal, and the longitudinal girder.

[0031] Secondly, hoist the CW05P segment and CW06P segment, CW05P segment and CB05P segment are butt welded, CW06P segment and CB06P segment are butt welded, mainly for the welding of the inner bottom plate, the joint of the outer plate, and the large rib The butt joint of the CW05P segment and the CW06P segment, the welding of the inclined side plate and the longitudinal frame of the outer plate are mainly the butt joint at the turning circle of the bilge, where the node structure is the key area of precision control.

[0032] Finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com