Silicone molding plastic for encapsulating high-power electronic component

An electronic component, high-power technology, applied in the field of silicone molding compound, can solve the problems of product failure, component failure, high temperature decomposition of molding compound, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] GZ610 type silicone resin 30 parts glass fiber 20 parts

[0022] Silicon dioxide 46 parts Calcium stearate 0.5 parts

[0023] Benzoic acid 0.15 parts Basic lead carbonate 0.15 parts

[0024] 3 parts of ferric oxide

[0025] First, the glass fiber is dewaxed at a high temperature of 300°C; the silicon dioxide is dehumidified; calcium stearate, benzoic acid, and basic lead carbonate are ground;

[0026] Put the silicone resin into the mixer and knead for 5 minutes at 110°C; add glass fiber and silicon dioxide and knead for 10 minutes; add calcium stearate, basic lead carbonate, and ferric oxide and knead for 10 minutes, and wait for mixing Cool and pulverize after uniformity;

[0027] Add the cooled and pulverized material to a mixer for 5 minutes at 110°C, add benzoic acid and knead for 3 minutes, then press the material into flakes, and then pulverize after cooling to obtain high-power electronic component packaging. Keto molding compound.

Embodiment 2

[0029] GZ320 type silicone resin 32 parts glass fiber 20 parts

[0030] Silicon dioxide 44 parts Calcium stearate 0.5 parts

[0031] Benzoic acid 0.15 parts Basic lead carbonate 0.15 parts

[0032] 3 parts ferric oxide

[0033] First, the glass fiber is dewaxed at a high temperature of 300°C; the silicon dioxide is dehumidified; calcium stearate, benzoic acid, and basic lead carbonate are ground;

[0034] Put the silicone resin into the mixer and knead for 5 minutes at 110°C; add glass fiber and silicon dioxide and knead for 10 minutes; add calcium stearate, basic lead carbonate, and ferric oxide and knead for 10 minutes, and wait for mixing Cool and pulverize after uniformity;

[0035] Add the cooled and pulverized material to a mixer for 5 minutes at 110°C, add benzoic acid and knead for 3 minutes, then press the material into flakes, and then pulverize after cooling to obtain high-power electronic component packaging. Keto molding compound.

Embodiment 3

[0037] GZ610 type silicone resin 32.5 parts glass fiber 20 parts

[0038] 20 parts of silicon dioxide 23.5 parts of aluminum oxide

[0039] 0.5 parts of calcium stearate 0.15 parts of benzoic acid

[0040] 0.15 parts of basic lead carbonate 3 parts of ferric oxide

[0041] First, the glass fiber is dewaxed at a high temperature of 300°C; silicon dioxide and aluminum oxide are dehumidified; calcium stearate, benzoic acid, and basic lead carbonate are ground;

[0042] Put the silicone resin into the mixer and knead at 110°C for 5 minutes; add glass fiber, silicon dioxide, and aluminum oxide and knead for 10 minutes; add calcium stearate, basic lead carbonate, and ferric oxide for kneading 10 minutes, after mixing evenly, cool and pulverize;

[0043] Add the cooled and pulverized material to a mixer for 5 minutes at 110°C, add benzoic acid and knead for 3 minutes, then press the material into flakes, and then pulverize it after cooling to obtain high-power electronic component...

PUM

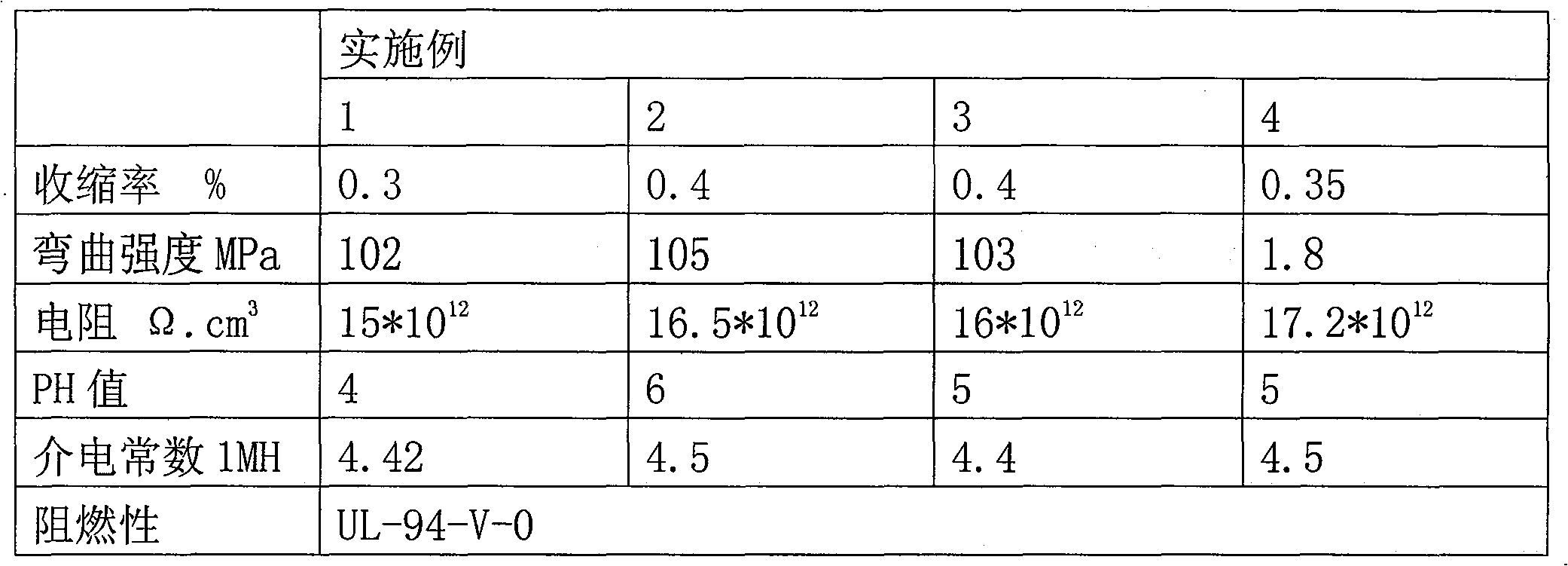

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com