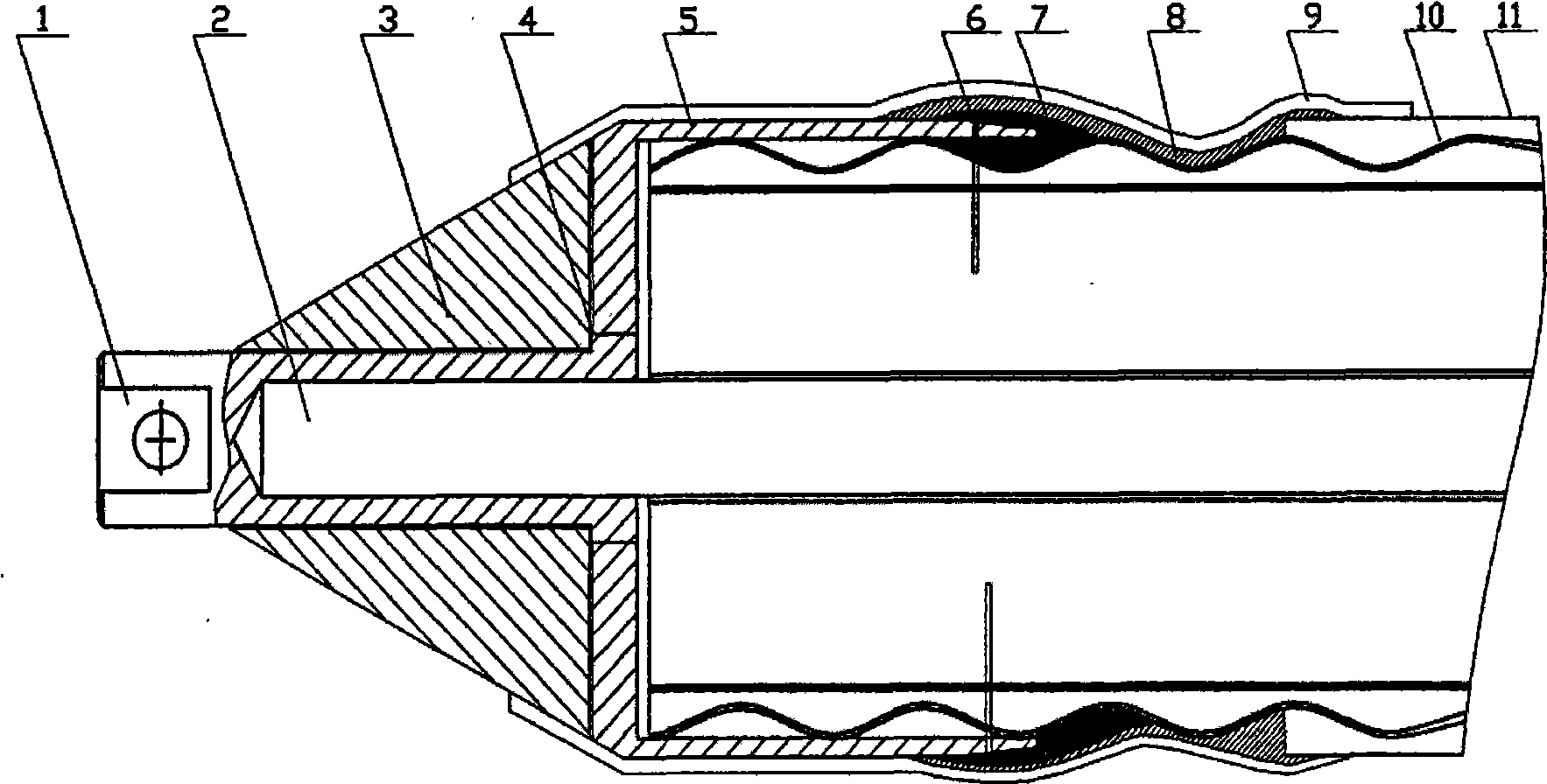

A drawing head of a high pressure cross linking cable

A cross-linked cable and traction head technology, applied in cable laying equipment and other directions, can solve problems affecting construction progress, damage, cable water seepage, etc., achieve reliable mechanical strength and waterproof sealing performance, solve problems of pipe jamming and convenient connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

[0010] as attached figure 1 As shown, the high-voltage cross-linked cable pulling head of the present invention is composed of a drawing rod 1, a cable conductor 2, a guide cone 3, a steel sleeve 5, a fixing screw 6, a lead seal 7, a waterproof tape 8, a heat shrinkable sleeve 9, a metal sleeve 10, The cable outer sheath 11 is formed, the drawbar 1 is welded 4 on the steel sleeve 5, the guide taper sleeve is on the drawbar, the steel sleeve is provided with fixing screw holes, and the 3 fixing screw holes form 120 degrees. The steel sleeve is fixed on the cable body by fixing screws, the steel sleeve is welded to the cable metal sleeve, the winding waterproof tape is installed at the connection between the steel sleeve and the cable metal sleeve, the heat shrinkable sleeve is installed on the steel sleeve, and the draw bar is connected to the cable conductor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com