Photosensitized composite material, three-dimensional memory material and recording medium, optical power limiting material and element, photocuring material and stereolithography system, and fluoresc

一种复合材料、多光子的技术,应用在多光子吸收材料领域,能够解决应用领域仅限、跃迁效率低、三维光记录介质方法没有描述等问题,达到高分辨率、提高跃迁效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

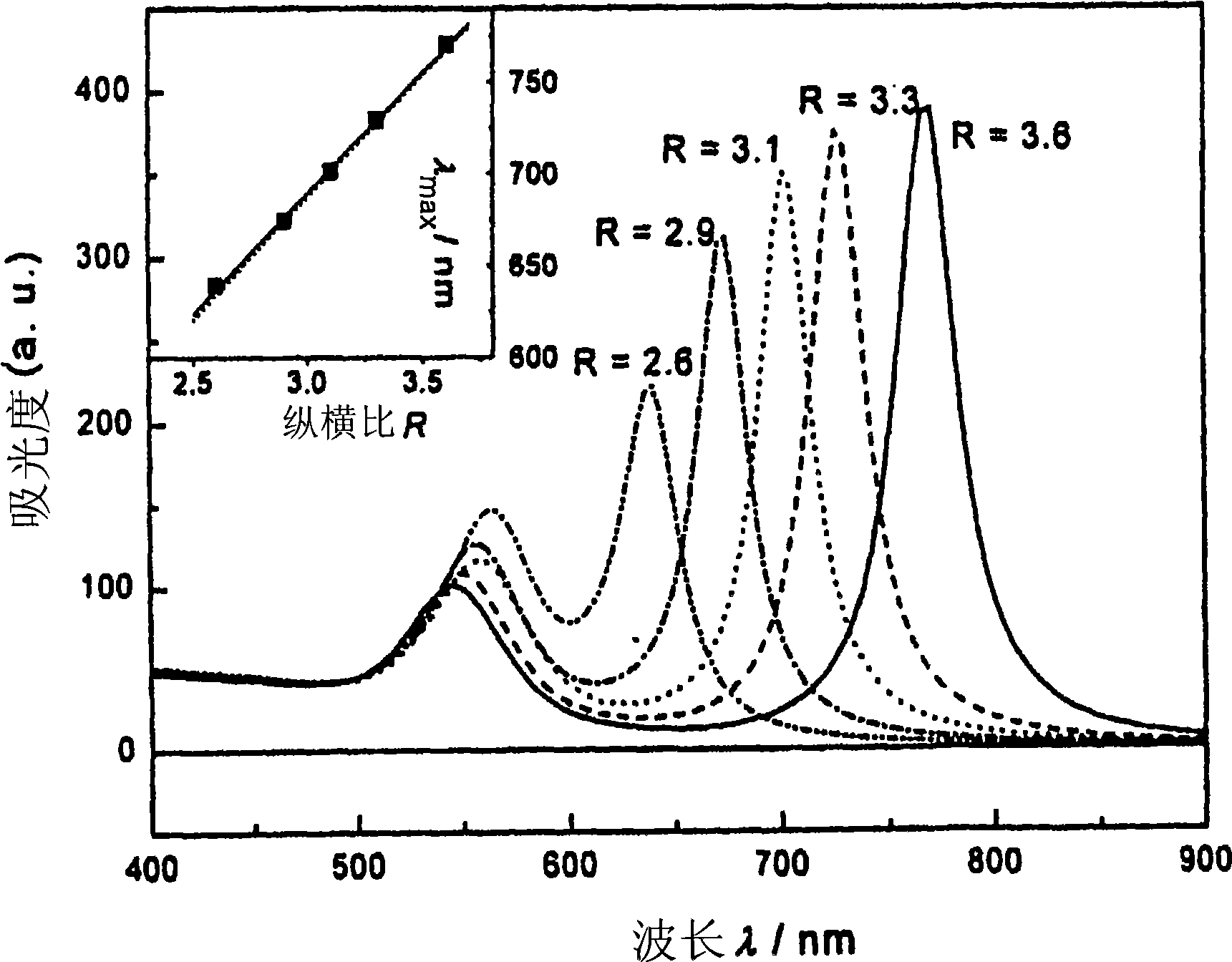

[0183] [144] First, 70 mL of a 0.18 mol / L cetyltrimethylammonium bromide aqueous solution, 0.36 mL of cyclohexane, 1 mL of acetone, and 1.2 mL of a 0.1 mol / L silver nitrate aqueous solution were mixed and stirred. After adding 0.3 mL of 0.24 mol / L chloroauric acid aqueous solution, 0.3 mL of 0.1 mol / L ascorbic acid aqueous solution was added, and it was confirmed that the color of chloroauric acid disappeared. Then, the solution was transferred into a vessel and irradiated with ultraviolet light having a wavelength of 254 nm by a low-pressure mercury lamp for 20 minutes. Therefore, a gold nanorod dispersion solution with an absorption peak wavelength of about 800 nm is obtained. The dispersed solution was placed in a centrifuge to separate and precipitate gold nanorod components. The supernatant was removed and water was added to the dispersion solution. Repeat centrifugation several times to remove excess cetyltrimethylammonium bromide dispersant.

Embodiment 2

[0185] [145] First, 70 mL of a 0.18 mol / L aqueous solution of cetyltrimethylammonium bromide, 0.36 mL of cyclohexane, 1 mL of acetone, and 1.0 mL of a 0.1 mol aqueous solution of silver mononitrate were mixed and stirred. After adding 0.3 mL of 0.24 mol / L chloroauric acid aqueous solution, 0.3 mL of 0.1 mol / L ascorbic acid aqueous solution was added, and it was confirmed that the color of chloroauric acid disappeared. Then, the solution was transferred into a vessel and irradiated with ultraviolet light having a wavelength of 254 nm by a low-pressure mercury lamp for 20 minutes. Therefore, a gold nanorod dispersion solution with an absorption peak wavelength of about 760 nm is obtained. The dispersed solution was placed in a centrifuge to separate and precipitate gold nanorod components. The supernatant was removed and water was added to the dispersion solution. Repeat centrifugation several times to remove excess cetyltrimethylammonium bromide dispersant.

Embodiment 3

[0187] [146] First, 70 mL of a 0.18 mol / L cetyltrimethylammonium bromide aqueous solution, 0.36 mL of cyclohexane, 1 mL of acetone, and 1.5 mL of a 0.1 mol / L silver nitrate aqueous solution were mixed and stirred. After adding 0.3 mL of 0.24 mol / L chloroauric acid aqueous solution, 0.3 mL of 0.1 mol / L ascorbic acid aqueous solution was added, and it was confirmed that the color of chloroauric acid disappeared. Then, the solution was transferred into a vessel and irradiated with ultraviolet light having a wavelength of 254 nm by a low-pressure mercury lamp for 20 minutes. Therefore, a gold nanorod dispersion solution with an absorption peak wavelength of about 840 nm was obtained. The dispersed solution was placed in a centrifuge to separate and precipitate gold nanorod components. The supernatant was removed and water was added to the dispersion solution. Repeat centrifugation several times to remove excess cetyltrimethylammonium bromide dispersant.

[0188] (Replacement Tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com