Five Elements Healthy Capsules

A technology of capsules and raw materials, which is applied in the direction of capsule delivery, anti-toxic agents, plant raw materials, etc., can solve the problems of uneven health care functions of health care products, and achieve the effects of protecting the liver, reducing blood lipids, and reducing the oxygen consumption of the heart and thigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

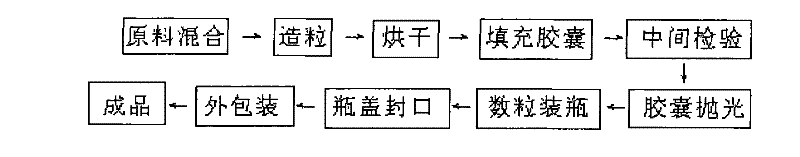

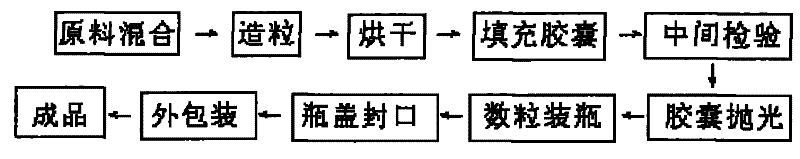

[0011] The steps of the preparation method are:

[0012] (1) Raw material mixing: according to the raw material formula: mix Cordyceps sinensis, Ganoderma lucidum, Hericium erinaceus, fungus and black tea evenly;

[0013] (2) Granulation: the mixed material is granulated by a granulator;

[0014] (3) Drying: place the granulated material in a dryer for hot air drying, keep the temperature at 50°C for 120 minutes, and dehydrate to a water content of 5wt%;

[0015] (4) Capsule filling: the dehydrated raw material granules are filled into capsules with a capsule filling machine;

[0016] (5) Intermediate inspection: check the filling quality during the filling process;

[0017] (6) Capsule polishing: put the filled capsule into a capsule polishing machine for polishing;

[0018] (7) Counting bottling: bottling the polished capsules with a counting board;

[0019] (8) bottle cap sealing: the bottle with capsule is sealed with a sealing machine;

[0020] (9) Outer packaging: p...

Embodiment 1

[0024] The parts by mass of each component of the raw material: 5 parts of Cordyceps sinensis, 10 parts of Ganoderma lucidum, 5 parts of Hericium erinaceus, 5 parts of white fungus, and 5 parts of black tea.

[0025] The steps of the preparation method are:

[0026] (1) Raw material mixing: according to the raw material formula: mix Cordyceps sinensis, Ganoderma lucidum, Hericium erinaceus, fungus and black tea evenly;

[0027] (2) Granulation: the mixed material is granulated by a granulator;

[0028] (3) Drying: place the granulated material in a dryer for hot air drying, keep the temperature at 50°C for 120 minutes, and dehydrate to a water content of 5wt%;

[0029] (4) Capsule filling: the dehydrated raw material granules are filled into capsules with a capsule filling machine;

[0030] (5) Intermediate inspection: check the filling quality during the filling process;

[0031] (6) Capsule polishing: put the filled capsule into a capsule polishing machine for polishing; ...

Embodiment 2

[0037] 10 parts of Cordyceps fruiting body or 15 parts of mycelium powder, 20 parts of Ganoderma lucidum extract or 15 parts of fine powder, 15 parts of Hericium erinaceus extract or 10 parts of fine powder, 15 parts of white fungus extract or 10 parts of fine powder, black tea extract 5 servings.

[0038] The ganoderma lucidum extract, the Hericium erinaceus extract, the white fungus extract and the black tea extract all use commercially available raw materials.

[0039] The steps of the preparation method are:

[0040] (1) Raw material mixing: according to the raw material formula: mix Cordyceps sinensis, Ganoderma lucidum, Hericium erinaceus, fungus and black tea evenly;

[0041] (2) Granulation: the mixed material is granulated by a granulator;

[0042] (3) Drying: place the granulated material in a dryer for hot air drying, keep the temperature at 50°C for 120 minutes, and dehydrate to a water content of 5wt%;

[0043] (4) Capsule filling: the dehydrated raw material g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com