Double-roller type extruding and granulation device and granulation process flow thereof

A technology of extrusion granulation and process flow, applied in the field of counter-roll extrusion granulation device, can solve problems such as difficult to detect components, achieve the effect of improving reliability, reducing plant height and investment, and ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

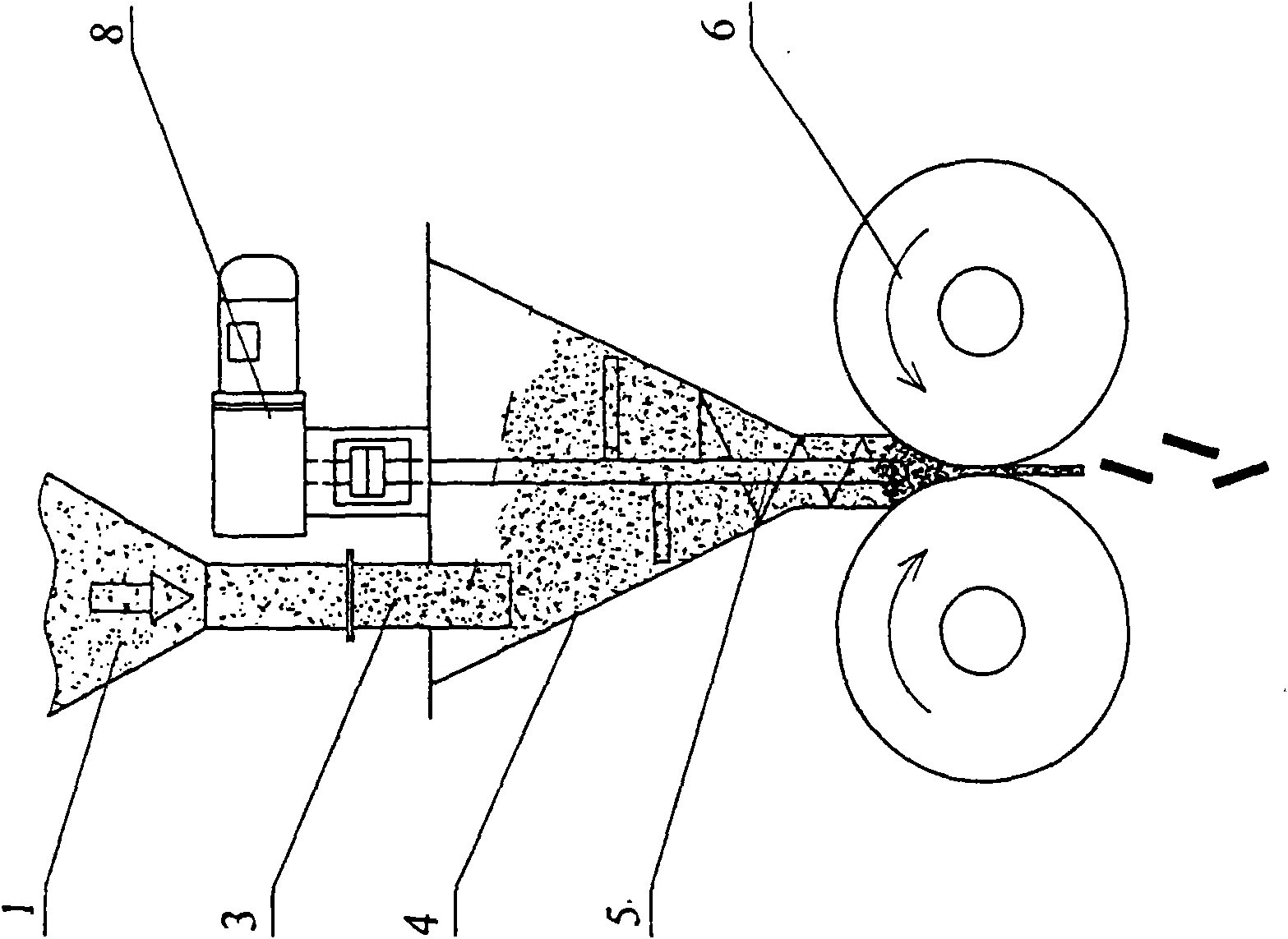

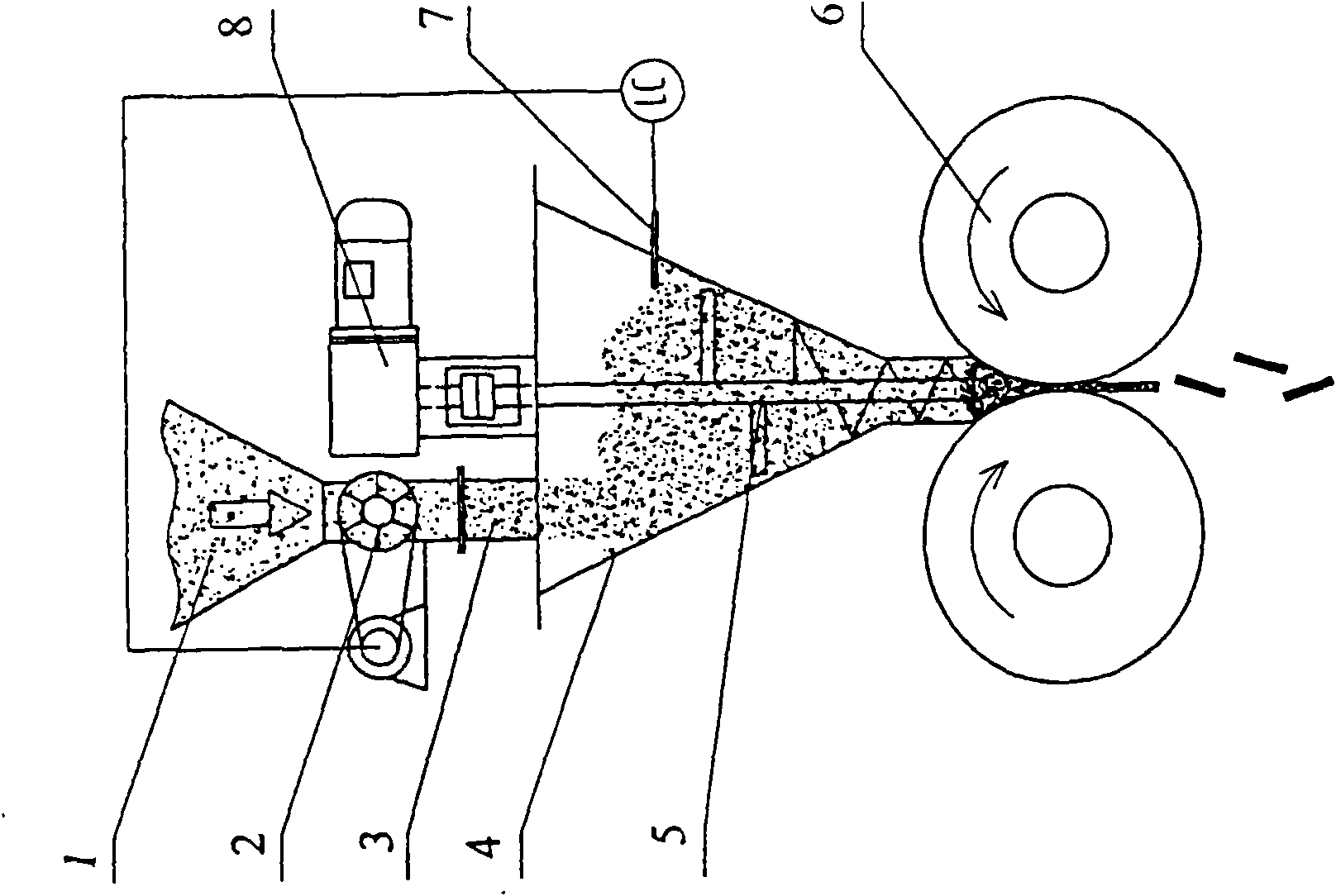

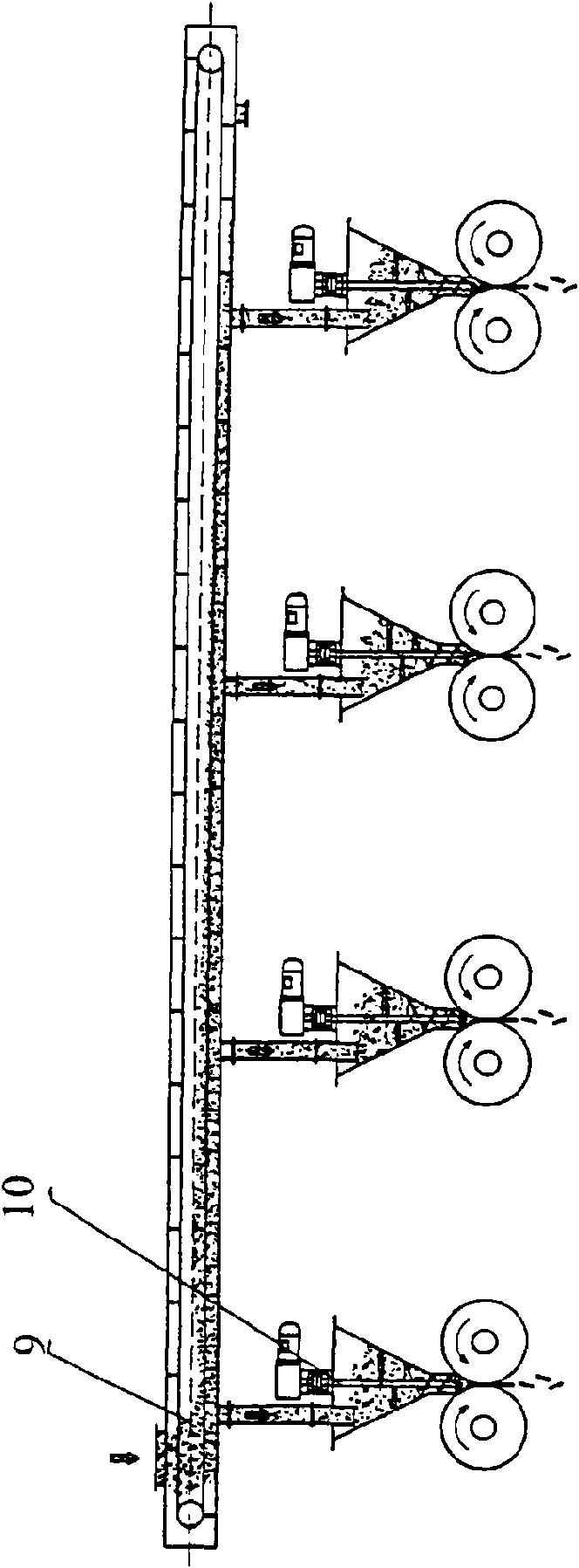

[0012] Control attached figure 1 , its structure is to include the material level automatic constant pipe 3, the forced feeder 5 and the roller extrusion granulator 6, wherein the automatic material level constant pipe 3 is inserted into the forced feeder hopper 4 of the forced feeder 5 from the top The required depth inside is fixed, and the automatic constant pipe 3 of material level is inserted into the hopper of the forced feeder from the top of the device, and the depth of its insertion is 5%-30% of the height of the hopper of the forced feeder. Forced feeder 5 links to each other with the roller extrusion granulator 6 that is installed below it. There is no need for intermediate silos and dosing devices as well as material level detection devices. Utilizing the characteristics of unidirectional pressure transmission of solid powder, through the material level automatic constant tube 3 at the feed inlet, the material level in the hopper 4 of the forced feeder is kept con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com