Bell combined frog repair welding technique

A process method and frog technology, applied in the field of bell combination frog welding repair technology, to achieve the effect of stable and reliable performance, good quality after welding repair, and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Before performing welding repair, the quality judgment of the damaged part of the bell combination frog should be carried out first:

[0024] 1. Do not weld and repair any part of the Bell combination frog that is broken.

[0025] 2. Confirm the damage degree of wing rail and center rail respectively:

[0026] (1) A small amount of defects or wear on the surface of the Bell combination frog will not affect the driving after grinding, and the maintenance "skylight" can be used to weld and repair online.

[0027] (2) When there are major defects such as surface wear, cracks, falling blocks, crushing and other major defects in Bell combined frogs, welding repairs can be made on the construction "skylight" timeline.

[0028] (3) When it is difficult to use the "skylight" time for welding repair, welding repair should be carried out offline or indoors.

[0029] (4) Welding repairs on the same part of Bell combined frogs should not exceed three times.

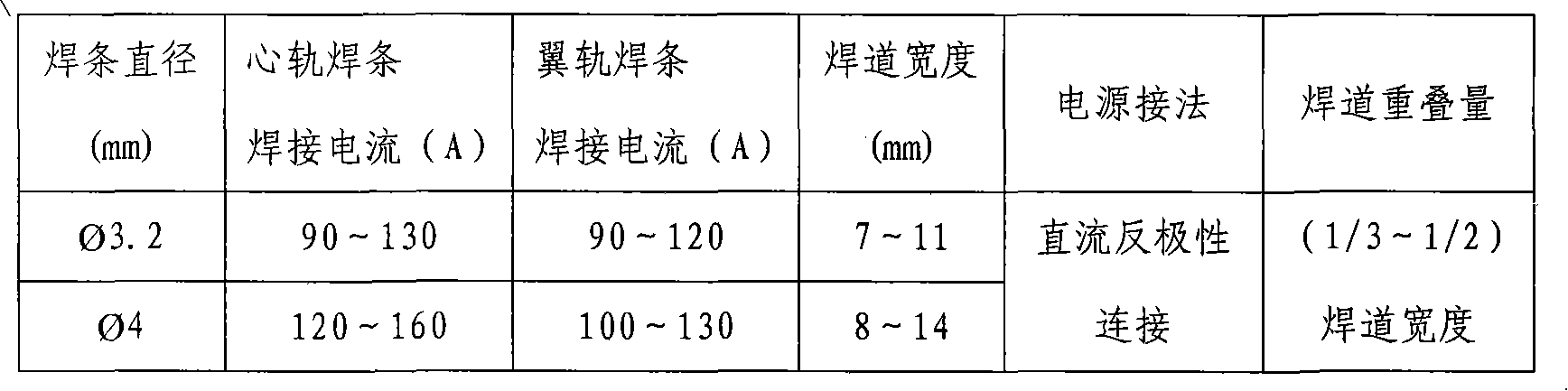

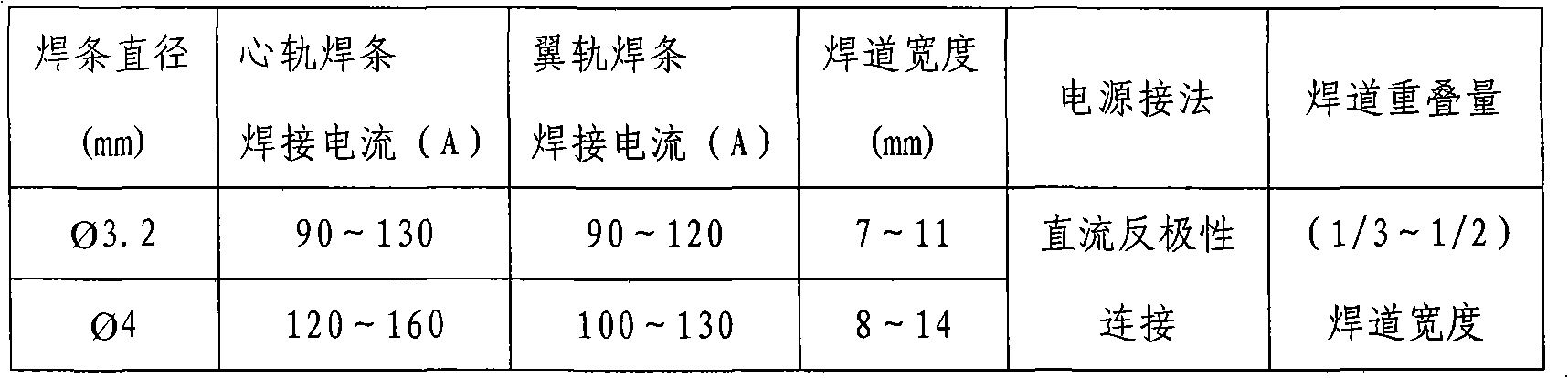

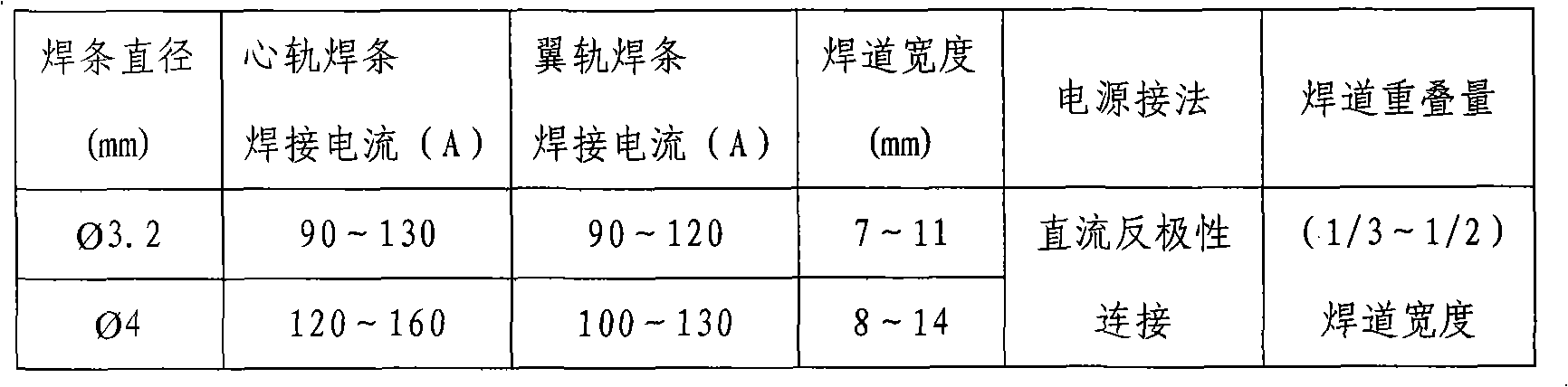

[0030] The process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com