Technique and device for producing glasses from non-plane glass

A production process and non-planar technology, applied in the field of silver mirror production process and its equipment, can solve the problems of low production efficiency, waste of production cost, increased cost investment, etc., so as to increase production cost, reduce production cost and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

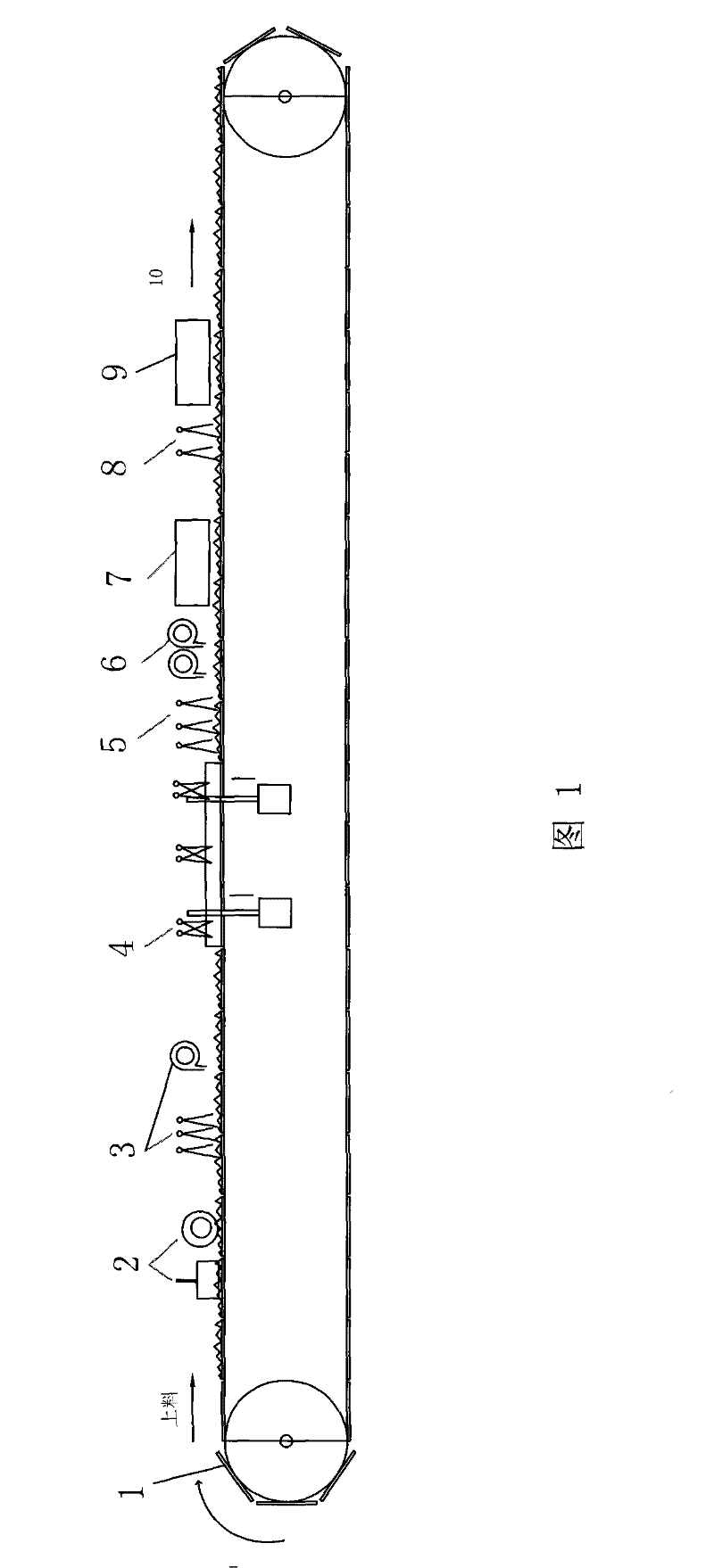

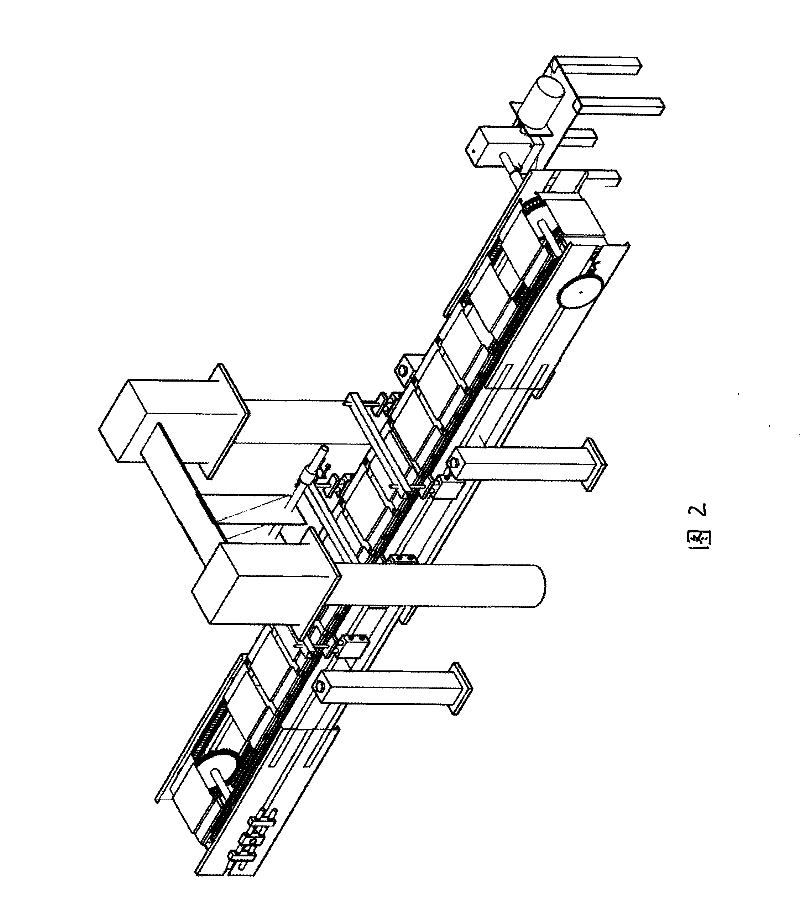

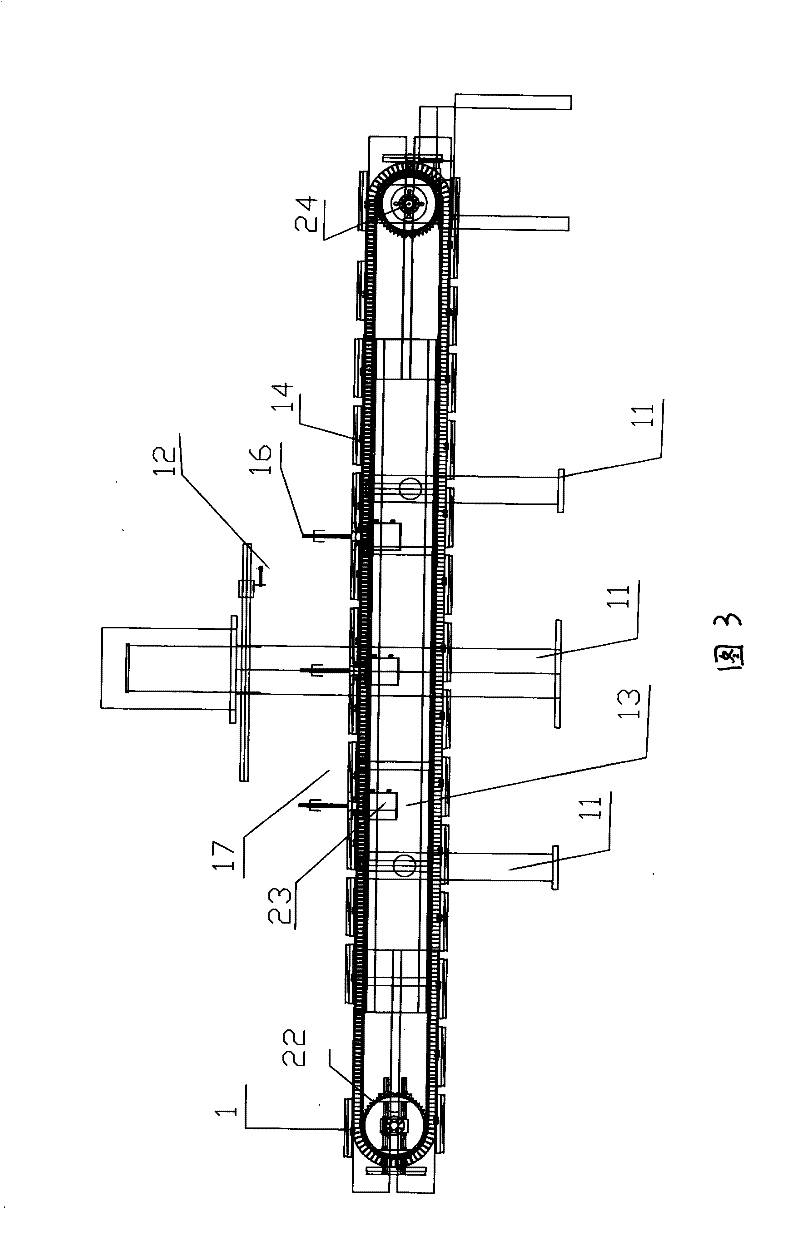

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: as Figure 5 As shown, silver mirror production is performed on a diamond-like eight-sided tapered glass body with a height of 1.95mm

[0052] The first group: using the flat glass silver mirror production process, the silver nitrate solution used is 250 g / L

[0053] The second group: Spray with 8 g / L silver nitrate (no frame)

[0054] The third group: use 8 grams per liter of silver nitrate to spray (adopt surrounding frame of the present invention)

[0055] First of all, the eight-sided tapered glass body is covered with 220*220mm PVC plastic, and the PVC plastic film is used as a partial protection of the non-processed surface and positioning; it is put into the tray 18, and the material is loaded;

[0056] Then, carry out cleaning, use mechanical method to add selenium oxide powder to scrub or adopt ultrasonic wave to add surfactant to clean, clean and rinse with deionized water;

[0057] Secondly, use divalent tin ions to sensitize the glass surfac...

Embodiment 2

[0069] Embodiment 2: For example Figure 6 Concave condenser mirrors shown with a height of 22mm for silver mirror production

[0070] The first group: using the flat glass silver mirror production process, the silver nitrate solution used is 250 g / L

[0071] The second group: Spray with 8 g / L silver nitrate (no frame)

[0072] The third group: use 8 grams per liter of silver nitrate to spray (adopt surrounding frame of the present invention)

[0073] Firstly, silicone rubber is used as a partial protection of the non-processing surface and positioning; it is put into the tray 18 and loaded;

[0074] Then, carry out cleaning, use mechanical method to add selenium oxide powder to scrub or adopt ultrasonic wave to add surfactant to clean, clean and rinse with deionized water;

[0075] Secondly, use divalent tin ions to sensitize the glass surface, and rinse with deionized water after sensitization;

[0076] silver plating again,

[0077] The first group: spray 1 square mete...

Embodiment 3

[0087] Embodiment 3: for such as Figure 7 The shown three-shuttle mirror with a height of 17.23mm, two adjacent slopes are used as reflective surfaces for silver mirror production

[0088] The first group: using the flat glass silver mirror production process, the silver nitrate solution used is 250 g / L

[0089] The second group: Spray with 8 g / L silver nitrate (no frame)

[0090] The third group: use 8 grams per liter of silver nitrate to spray (adopt surrounding frame of the present invention)

[0091] Firstly, silicone rubber is used as a partial protection of the non-processing surface and positioning; it is put into the tray 18 and loaded;

[0092] Then, carry out cleaning, use mechanical method to add selenium oxide powder to scrub or adopt ultrasonic wave to add surfactant to clean, clean and rinse with deionized water;

[0093] Secondly, use divalent tin ions to sensitize the glass surface, and rinse with deionized water after sensitization;

[0094] silver platin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com