Method and device for removing coating solidifying volatile material in optical fibre drawing process

A wire drawing process and volatile technology, applied in the field of optical fiber processing, can solve the problems of gaseous volatiles that are difficult to completely remove from the surface coating of optical fibers, high thermal conductivity gases are expensive, and volatiles are not completely removed. The effect of improving the processing environment and avoiding pollution of the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

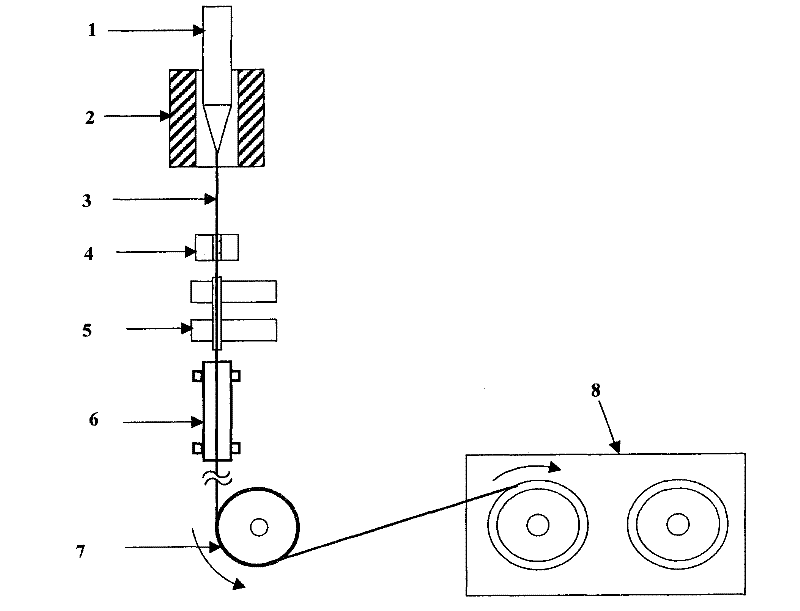

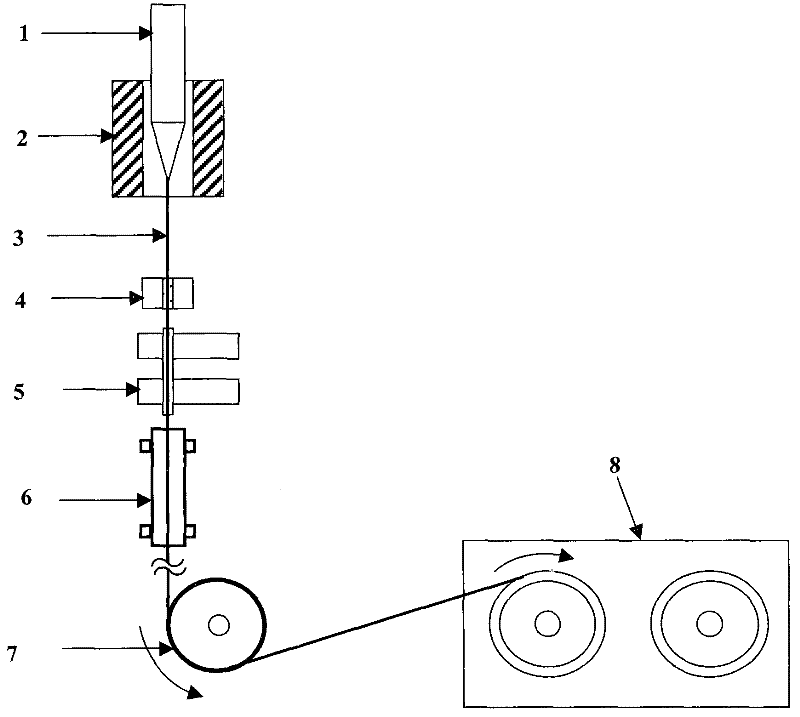

[0019] The processing process of the optical fiber includes: the preform rod 1 is heated and softened in the drawing furnace 2 to form the optical fiber 3, the optical fiber enters the coating coating device 4 after cooling and forming, the optical fiber surface is coated with the coating, and then enters the curing device 5 for coating curing. During the process, the optical fiber surface coating produces a large amount of volatile matter. After the optical fiber is cured, it enters the solid volatile matter removal device 6 to remove the cured volatile matter of the surface coating. After the removal process, it passes through the traction wheel 7 to the take-up wheel 8 to complete the optical fiber processing process.

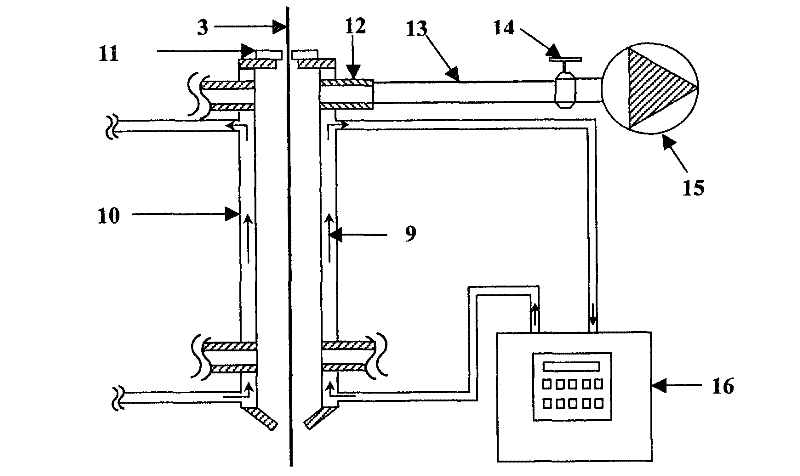

[0020] The device for removing coating surface volatiles of the present embodiment is as figure 2 , including a slender circular cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com