Polybutylene terephthalate material for car lamp decoration ring

A polybutylene terephthalate and decorative ring technology, which is applied in the field of polybutylene terephthalate engineering plastics, can solve problems such as the need for primer spraying, and achieve improved productivity, good solubility, and good The effect of dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 9

[0041] Embodiments 1 to 9: A polybutylene terephthalate material for car lamp decorative rings

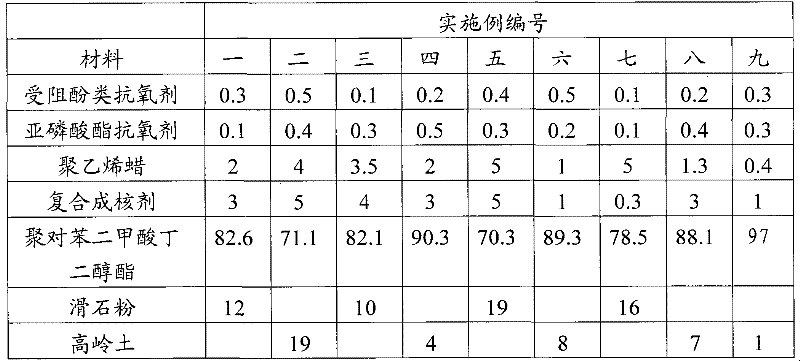

[0042] Embodiment one~nine material formulations are as follows:

[0043]

[0044] Preparation method: After weighing the materials in the formula, place them in a twin-screw extruder, extrude and granulate. The compositions of hindered phenolic antioxidants, phosphite antioxidants and composite nucleating agents are described in detail in tables.

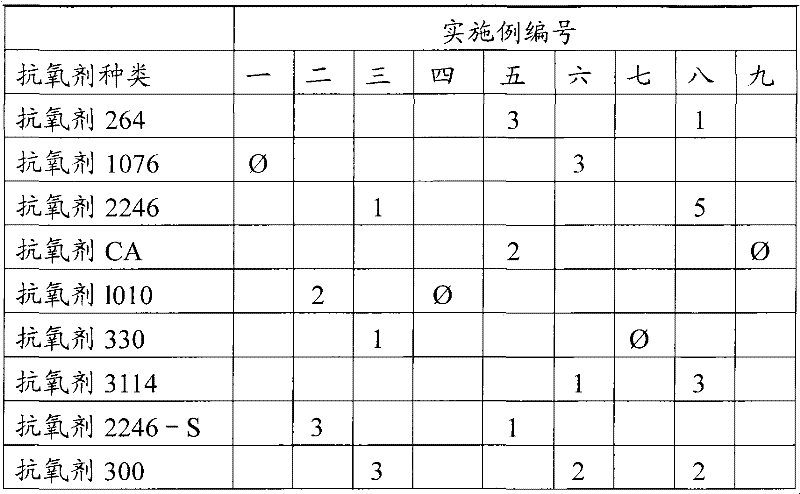

[0045] Hindered phenolic antioxidants are as follows:

[0046]

[0047] In the above table, the symbol Represents the choice of only one antioxidant, and the numbers represent the mass ratio relationship between hindered phenol antioxidants.

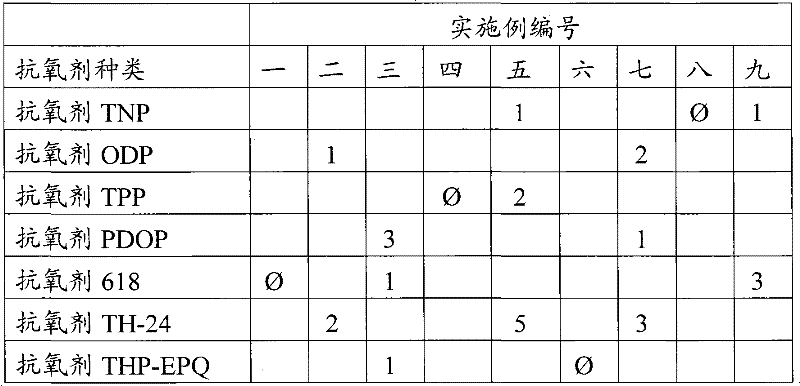

[0048] Phosphite antioxidants are as follows:

[0049]

[0050] In the above table, the symbol Represents the choice of only one antioxidant, and the number represents the mass ratio relationship between each phosphite antioxidant.

[0051] The composite nucleating agent is as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com