Constructing method for basic pit at the upper part of shield tunnel

A technology of shield tunneling, construction method, applied in the direction of infrastructure engineering, excavation, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

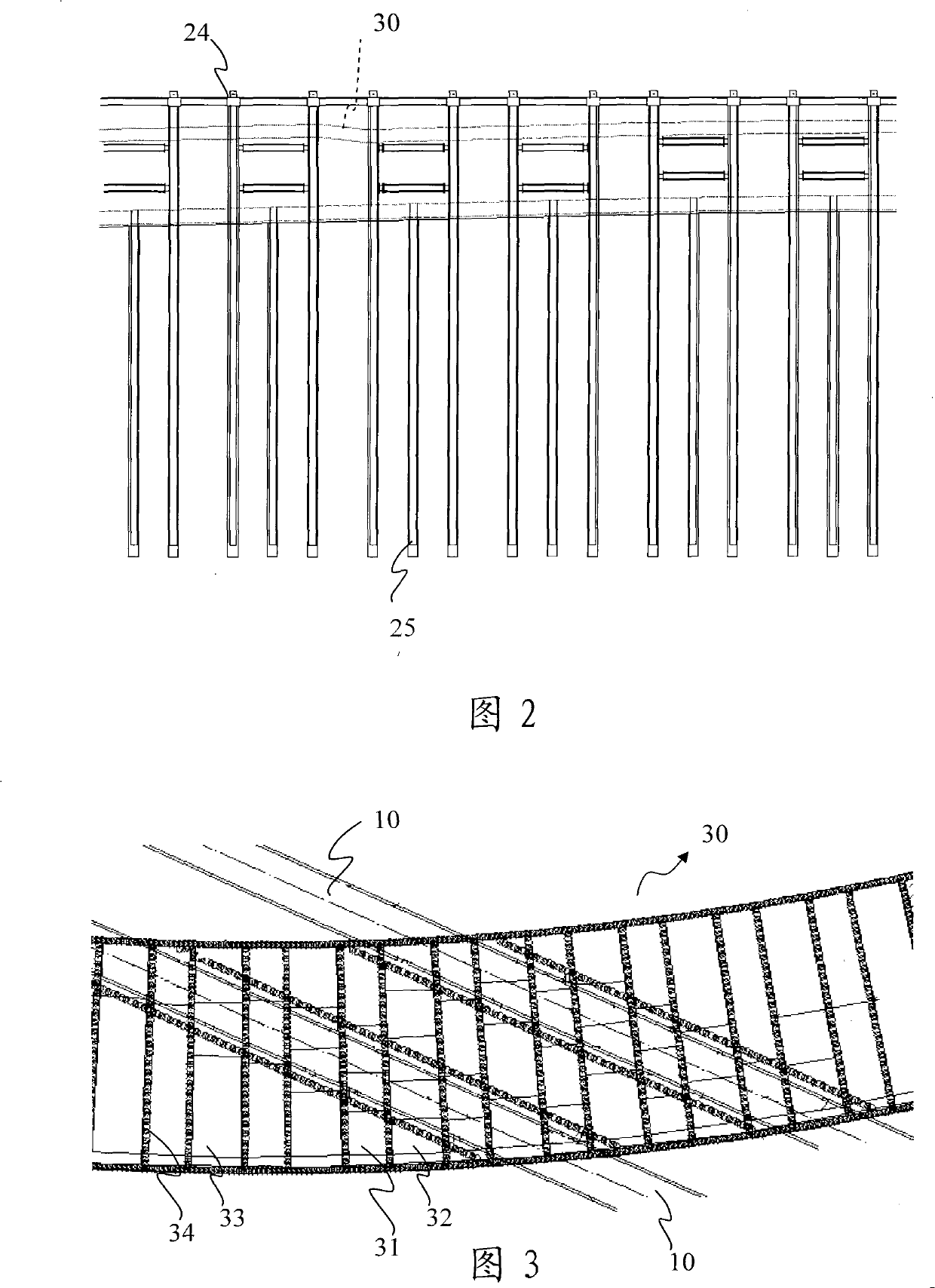

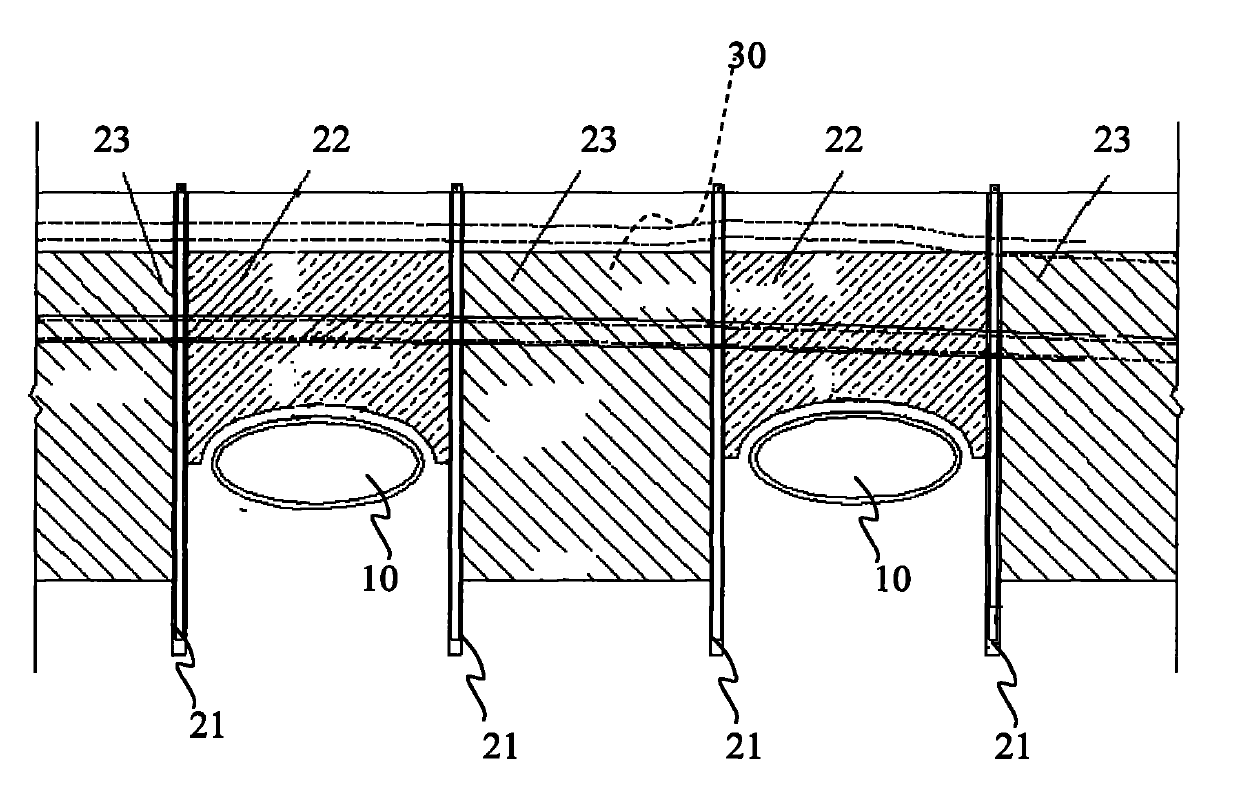

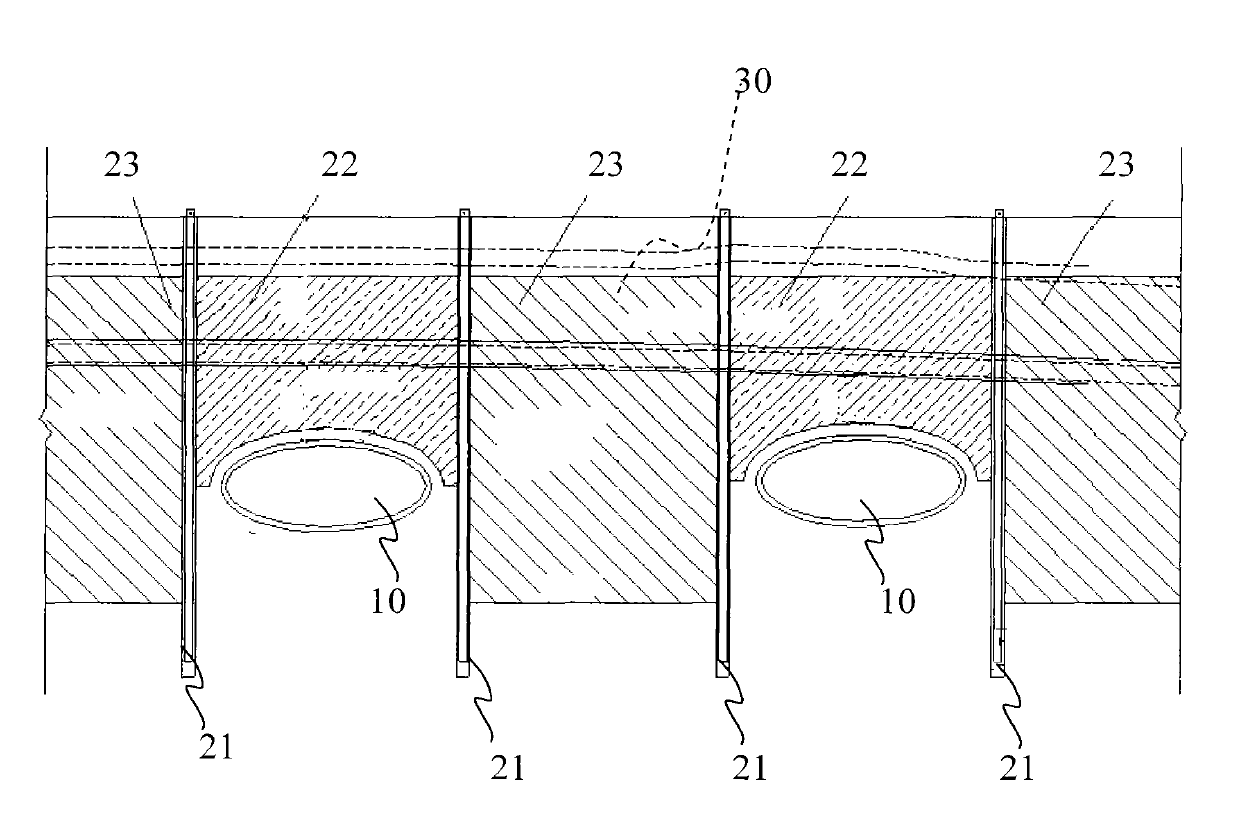

[0022] The foundation pit construction method of the present invention utilizes the principle of time and space effects, and proposes a complete construction method and a determination method for key parameters for the foundation pit construction above the shield tunnel with strict deformation requirements, so as to ensure that when the foundation pit is constructed above the shield tunnel, The structural deformation of the shield tunnel meets the current standards, which has a clear guiding significance for the actual construction. The method will be described in detail below in conjunction with a specific embodiment.

[0023] The excavation of a newly built tunnel in Shanghai crosses the main line of the subway, and the excavation of the shield tunnel on the upper section is about

[0024] 150m, 27.1m wide, the deepest excavation depth of the foundation pit is about 12.172m, the distance from the bottom of the foundation pit to the top of the tunnel structure is only about 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com