Method and device for measuring cylindrical spacer

A spacer and position measurement technology, which is applied in the direction of measuring devices, optical devices, optics, etc., can solve the problems of small edge range, high requirements for reference plane selection, time-consuming and labor-intensive efficiency, etc., and achieve high-efficiency positioning effect, high efficiency and pinpoint effect, effect of pinpoint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

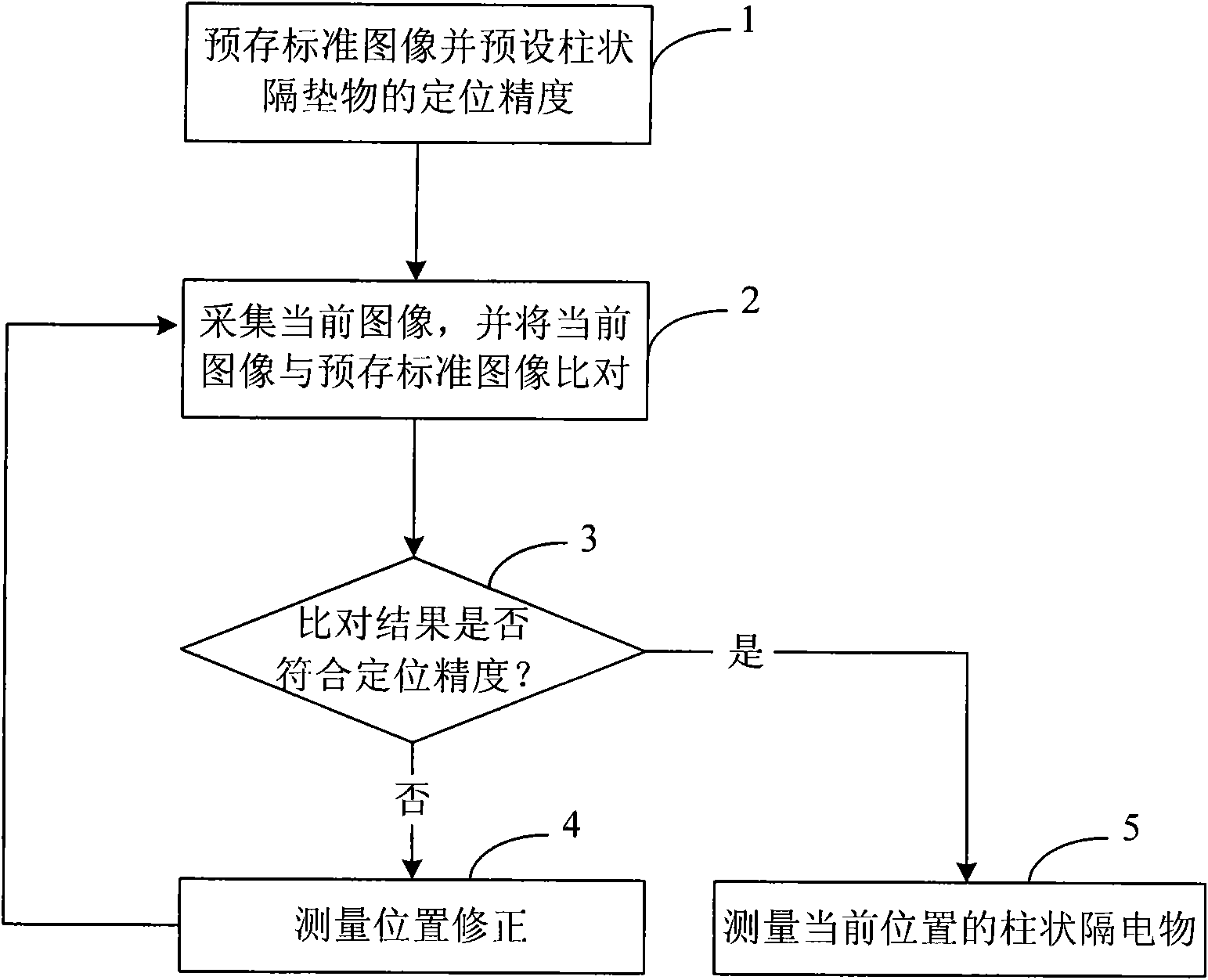

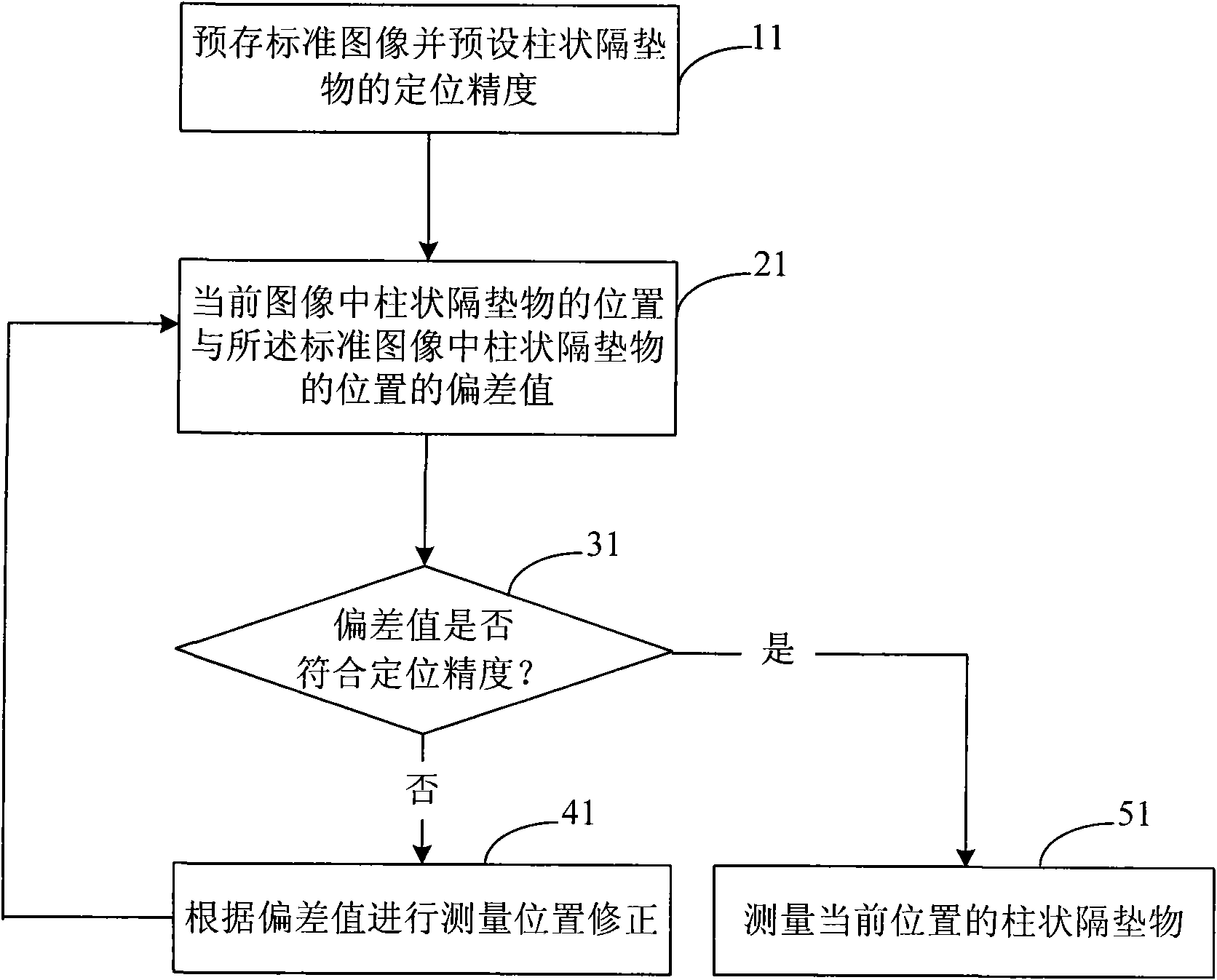

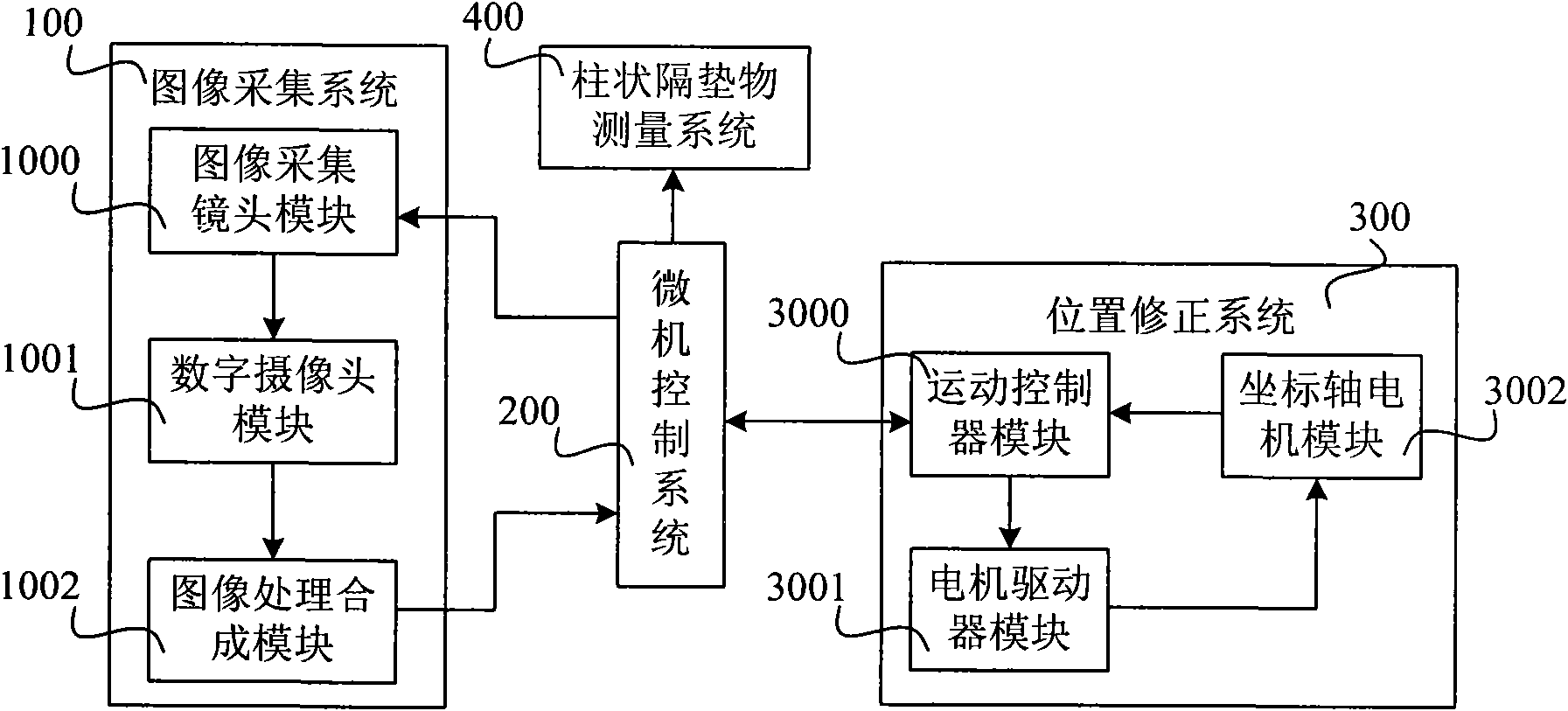

[0025] Such as figure 1 Shown is the flow chart of Embodiment 1 of the method for measuring columnar spacers of the present invention, the method includes the following steps:

[0026] Step 1. Pre-scan the standard image into the computer and pre-set the positioning accuracy of the position of the columnar spacer;

[0027] When measuring the height of the columnar spacer on the color filter or making a template with the columnar spacer inspection equipment, firstly, the ideal standard image is scanned into the computer for storage and stored in the preset columnar spacer at the same time. The positioning accuracy of the spacer position.

[0028] Step 2, collecting the current image of the position of the columnar spacer specified for measurement, and comparing the current image with the standard image;

[0029] The measuring lens is moved to a designated position for image scanning to obtain the current image of the designated columnar spacer, and the current image is scanne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com