Capacitance electronic type fuel sensor

A capacitive sensing and electronic technology, applied in liquid level indicators for physical variable measurement, etc., can solve the problems of difficult accurate measurement of capacitance parameters and excessively large distribution parameters, and achieve the effect of reducing errors and making it easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

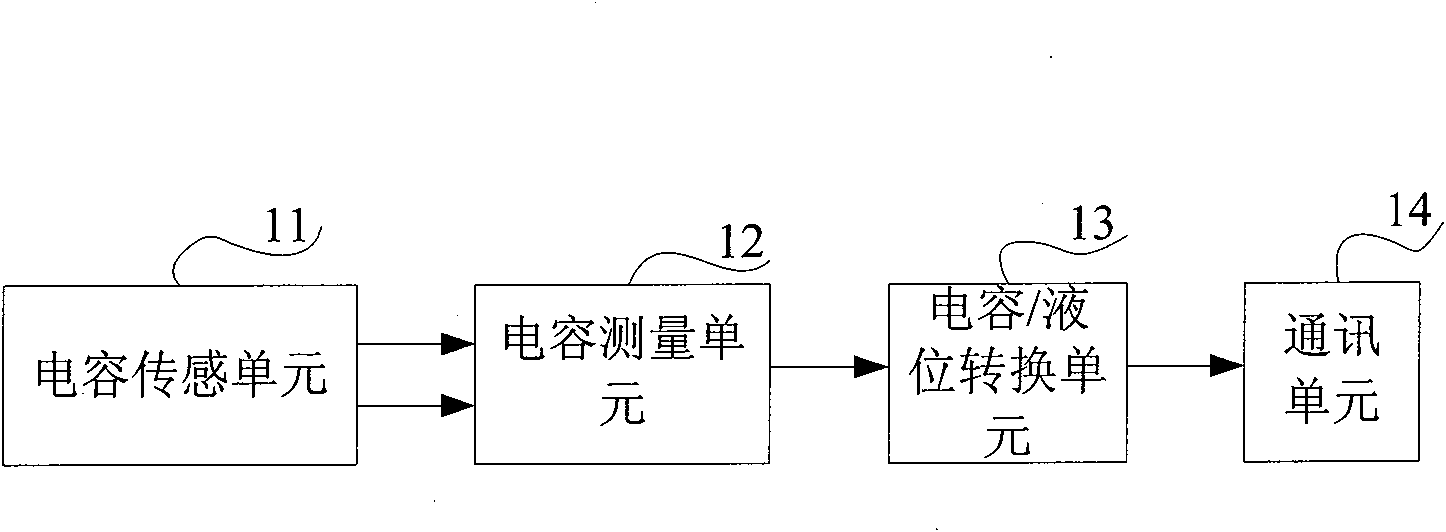

[0025] Such as figure 1 As shown, the present invention provides a capacitive electronic fuel sensor, which includes a capacitive sensing unit 11, a capacitive measuring unit 12, a capacitive / liquid level conversion unit 13 and a communication unit 14, wherein,

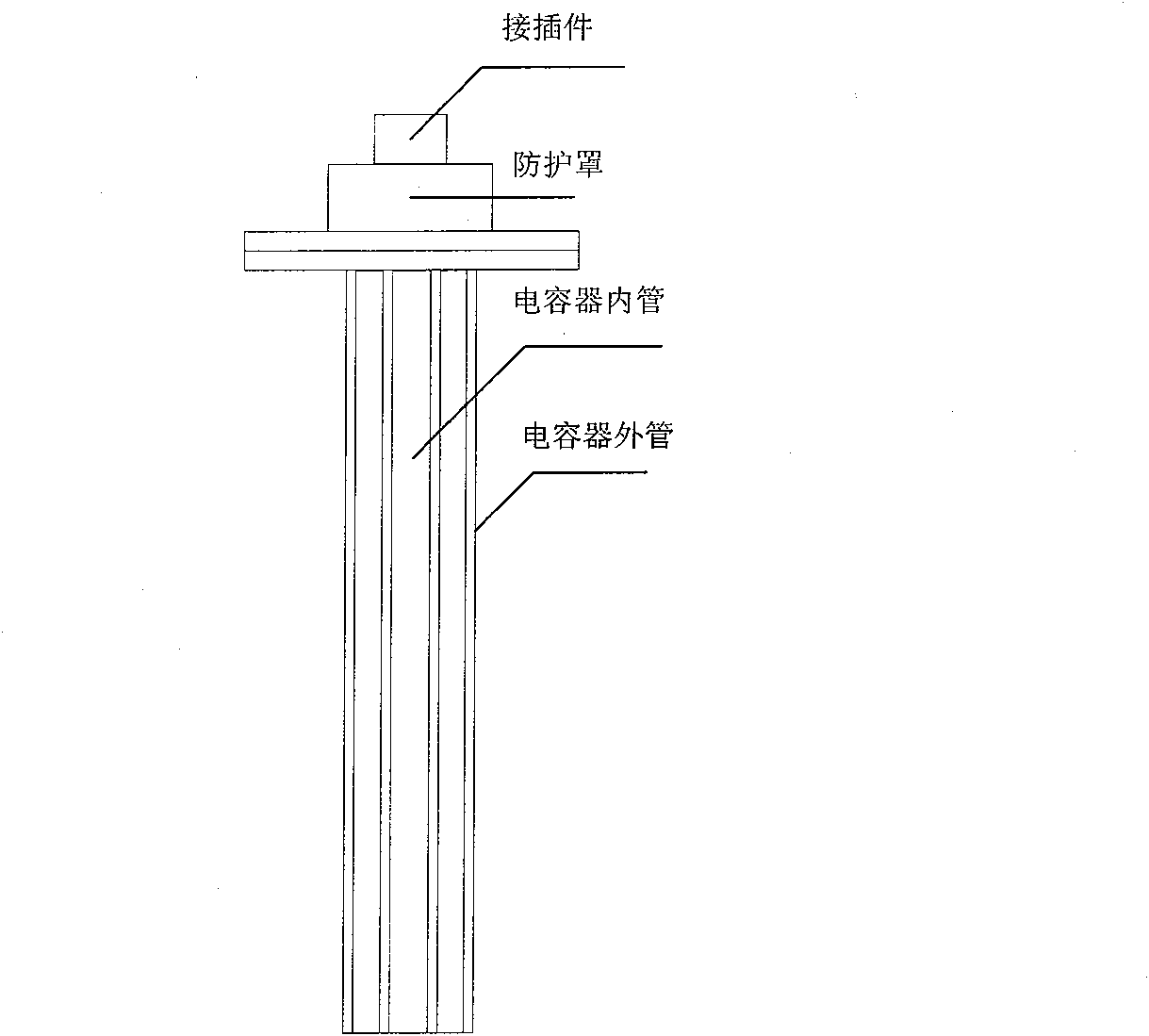

[0026] The capacitive sensing unit 11 is a combined tubular capacitive element, comprising a metal outer tube and a metal inner tube, the metal outer tube and the metal inner tube constitute a fuel level sensor capacitor; the capacitive sensing unit 11 is used for converting the fuel level to the corresponding capacitance value;

[0027] The metal outer tube and the metal inner tube of the capacitance sensing unit 11 are respectively connected to the input end of the capacitance measurement unit 12 through lead wires;

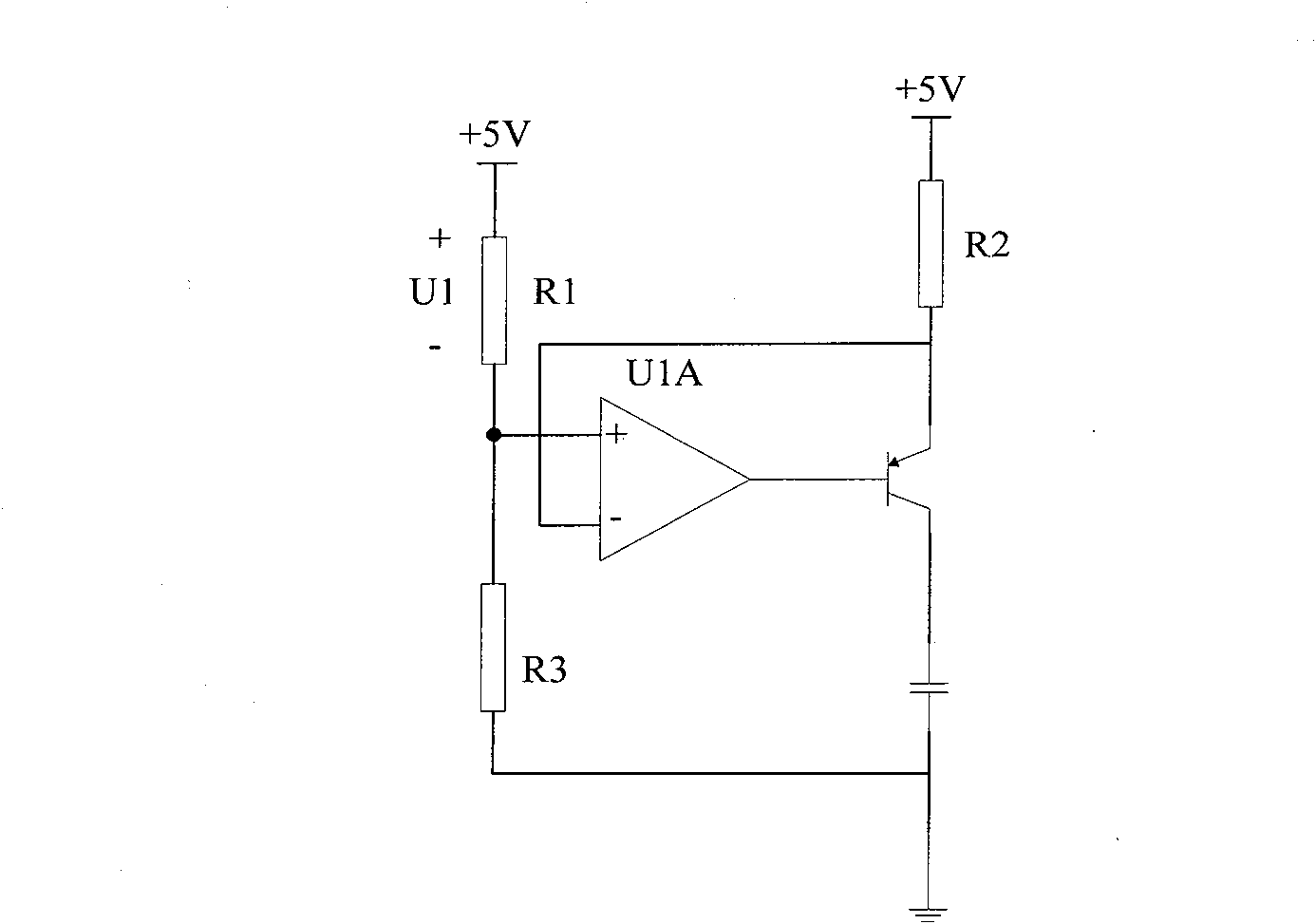

[0028] The capacitance measuring unit 12 is used to measure the capacitance value of the capacitance sensor unit 11;

[0029] The capacitance / liquid level conversion unit 13 is electrically connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com