Air-suction type space dust-charge test device

A test device and air-pumping technology, which is applied in the direction of electrostatic field measurement, etc., can solve the problems of large error in probe method measurement, narrow application range, and inability to meet the requirements of charged dust charge test, so as to ensure accuracy , the effect of low error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

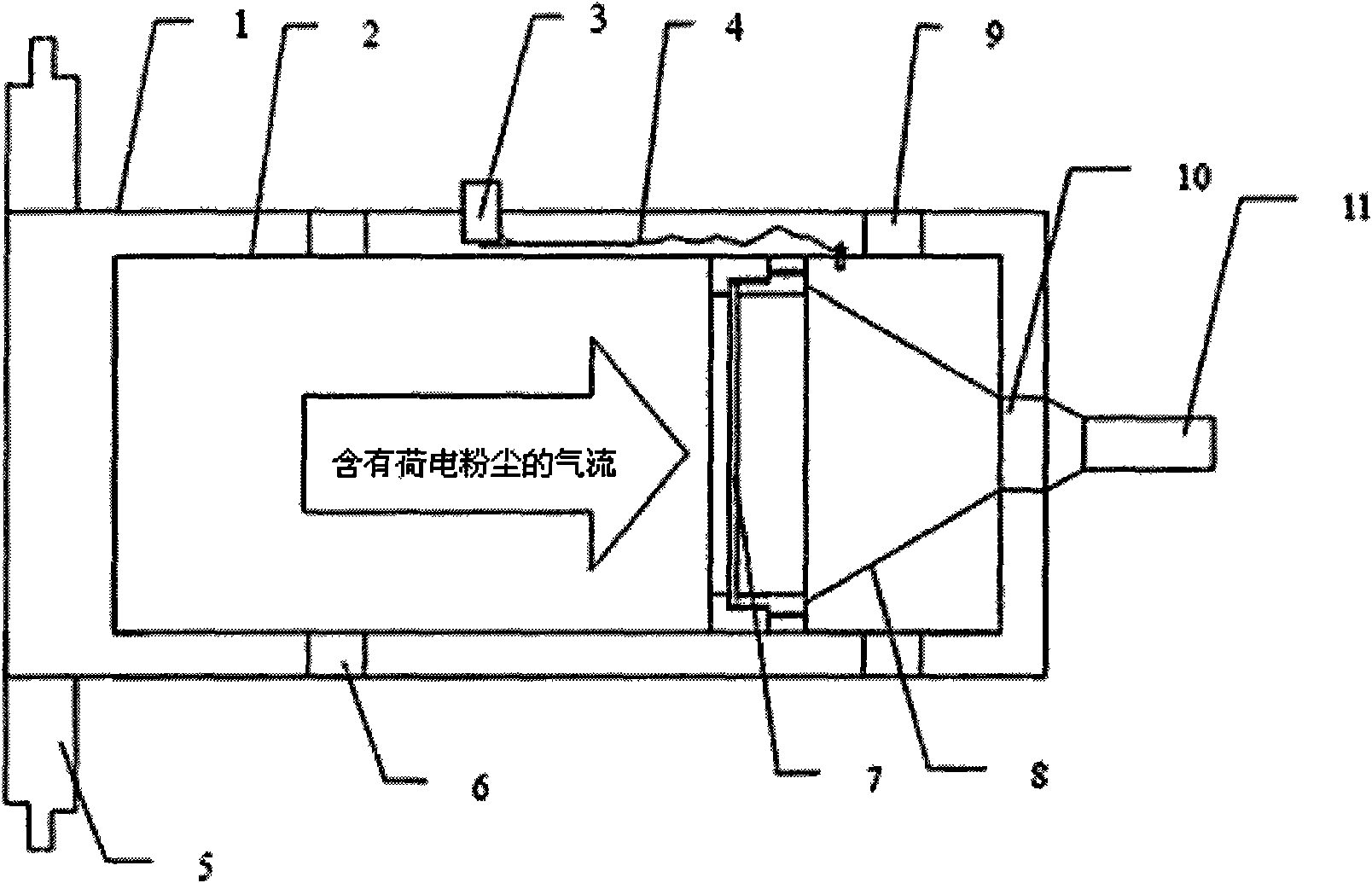

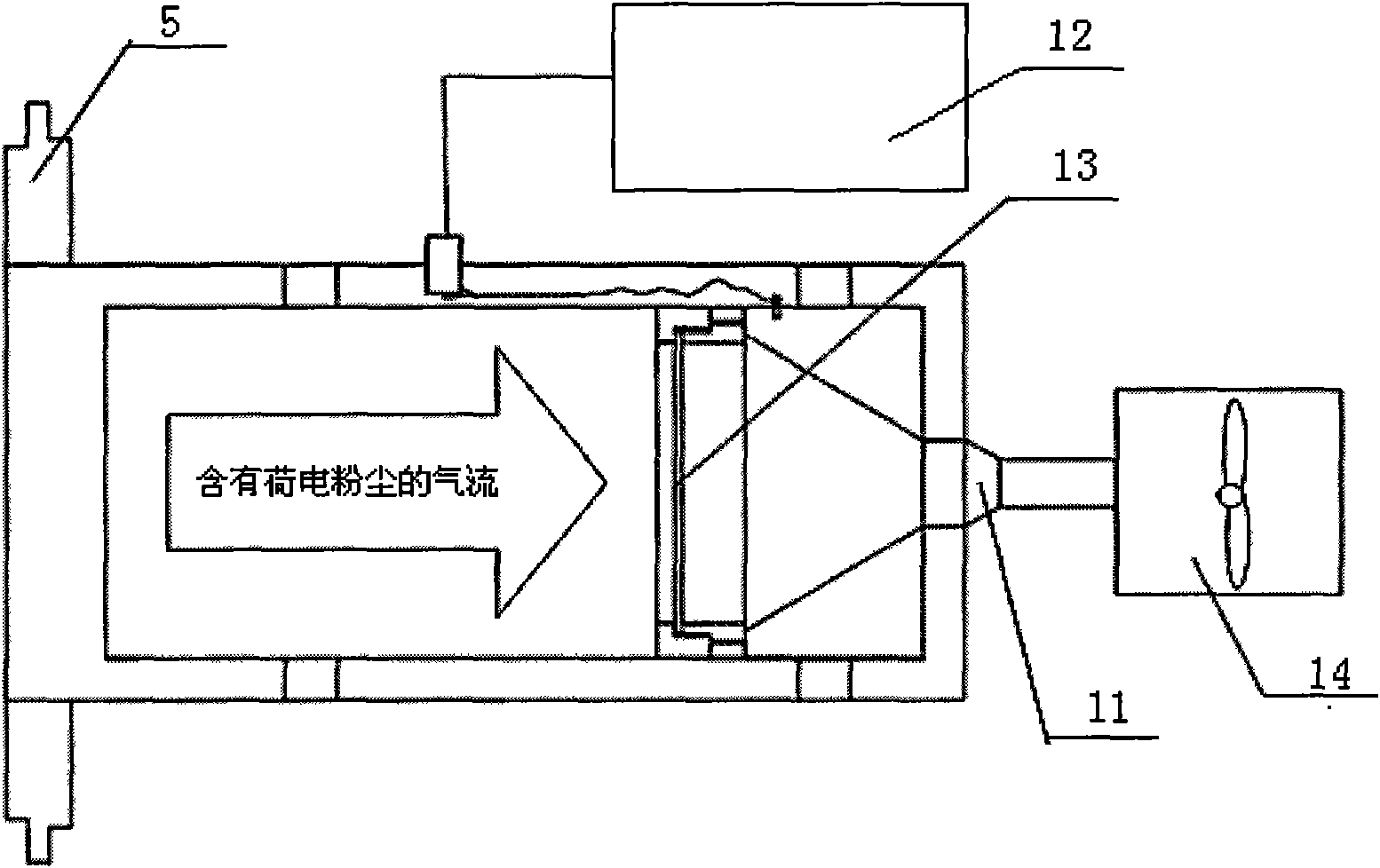

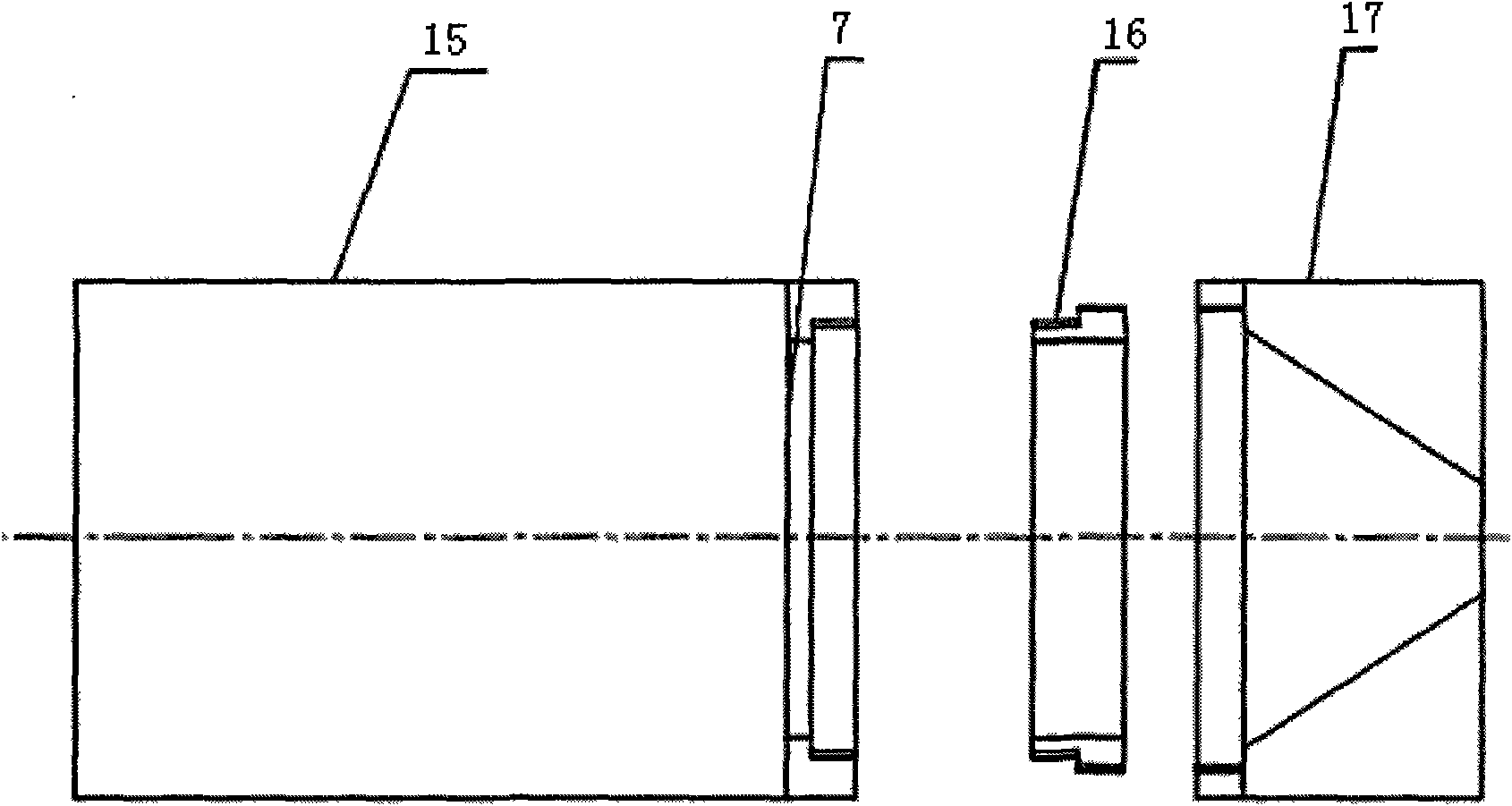

[0022] Example 1: Aspirated space dust charge test device, including outer test cylinder 1 and inner test cylinder 2, the opening side of the outer test cylinder 1 is provided with a flange 5 for connecting pipes or containers, and the inner test cylinder 2 is formed by the induction cylinder 15 and the current collecting suction nozzle 17 are composed of two parts, and the two parts are connected by a connecting piece 16. The connecting piece 16 is respectively connected to the two parts by threads, and the induction cylinder 15 of the inner test cylinder 2 is provided with a high-efficiency filter paper 13. The high-efficiency filter paper 13 is fixed by the clamping ring 7, which can prevent the high-efficiency filter paper 13 from moving or falling off when the airflow passes through. In addition, it is more convenient to replace the high-efficiency filter paper 13. An insulating ring is arranged between the inner test cylinder 2 and the outer test cylinder 1. The insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com