Substance joining method, substance joining device, joined body, and its manufacturing method

A joining method and joint body technology, applied in the direction of manufacturing tools, glass manufacturing equipment, welding equipment, etc., to achieve the effect of easy access and ease of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

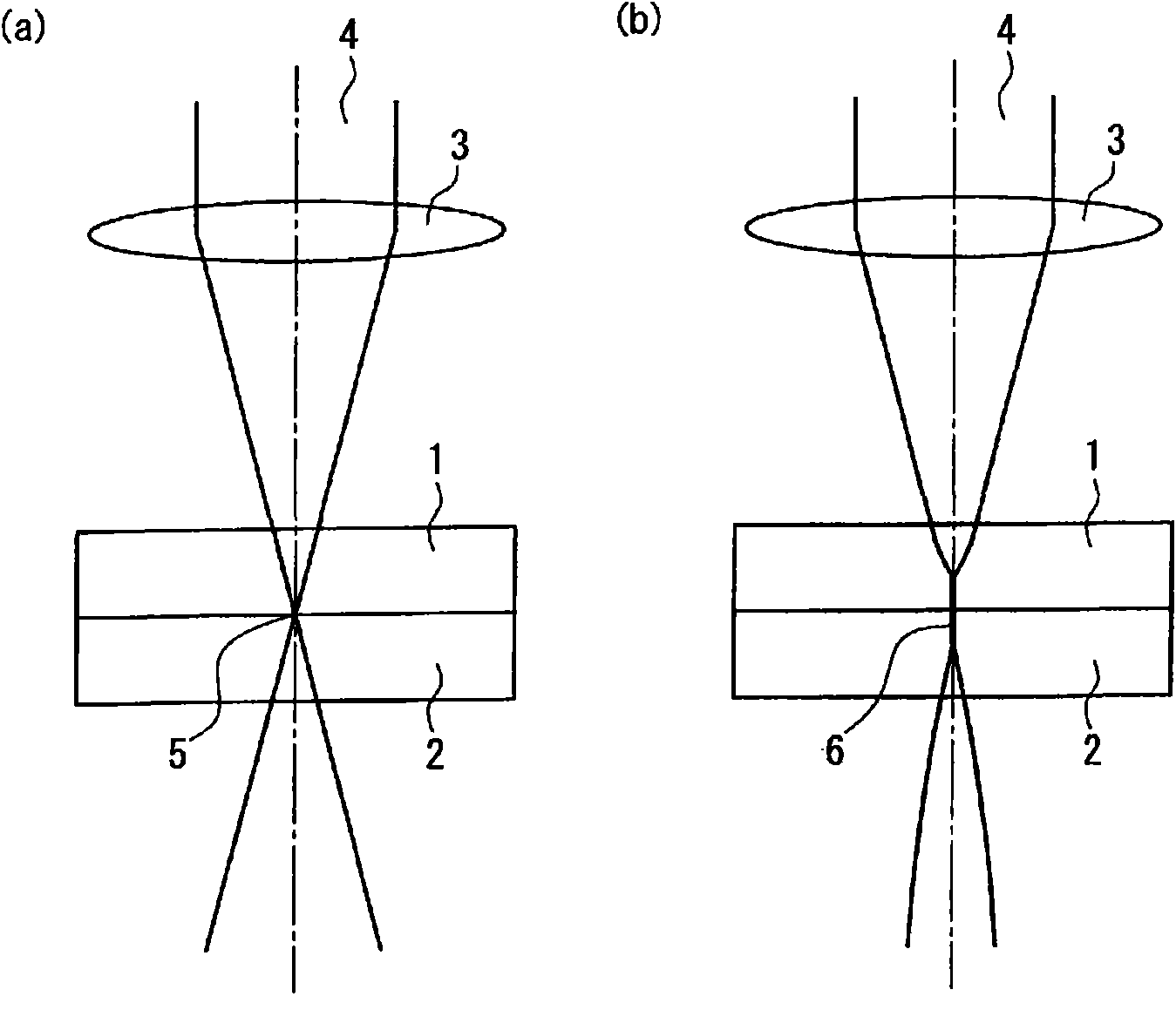

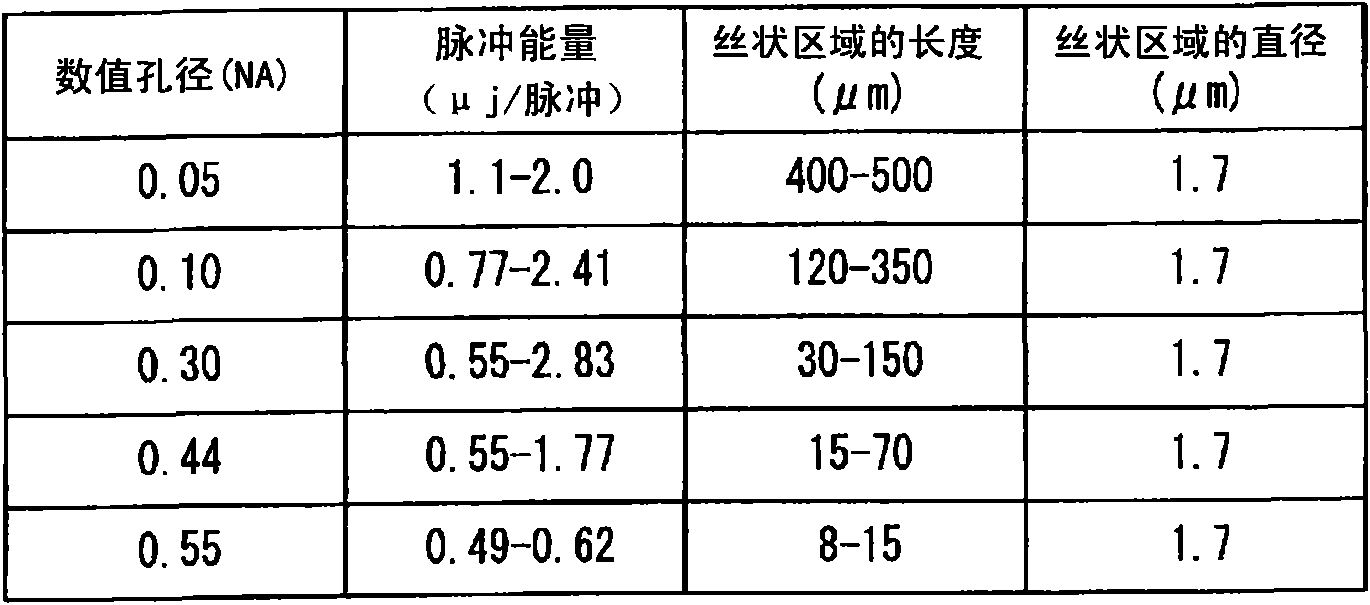

[0064] The method for joining the first substance of the present invention will be described below as the first embodiment; however, before describing the specific embodiments, the most important point in the joining method of this embodiment, that is, the principle of the filamentary region and its formation will be explained. illustrate.

[0065] When the ultra-short pulse laser beam with pulse width from femtosecond to picosecond level is incident on transparent materials such as glass, the laser beam basically has a Gaussian spatial intensity distribution, so in nonlinear media, the intensity of light is strong. The refractive index of the central part is higher than that of other parts, and the medium itself functions as a positive lens. Therefore, it is considered that a self-focusing action in which incident light is concentrated at one point occurs, and the beam diameter becomes extremely small after the ultrashort pulse laser beam propagates a finite distance in a tra...

no. 2 Embodiment approach

[0106] Next, a second embodiment of the joining method of the substance of the present invention will be described.

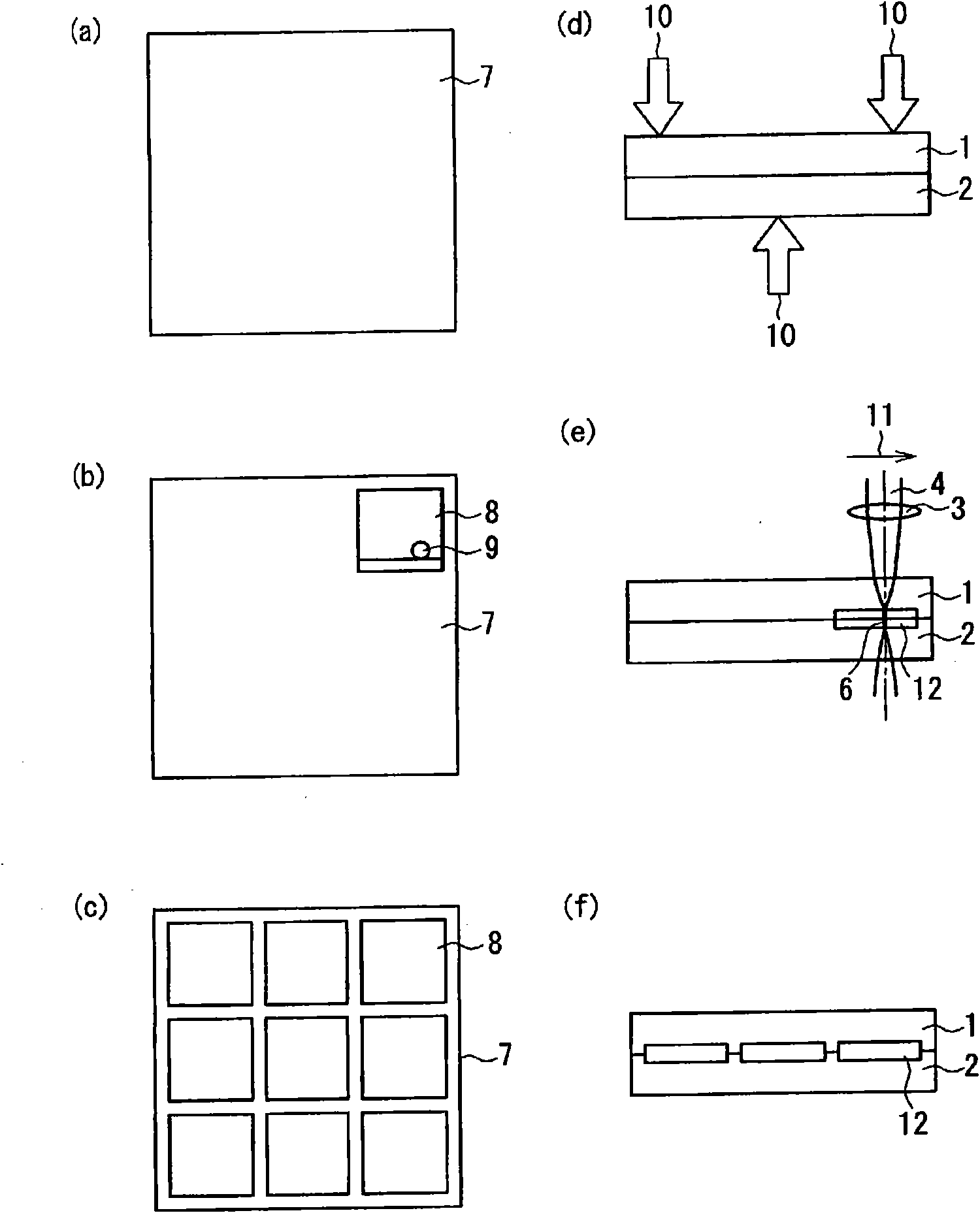

[0107] In the bonding method of the first substance of the present invention, as described above as the first embodiment, in adjusting the focusing conditions of the ultrashort pulse laser beam, the key point is to generate a filamentous region, and the second embodiment makes full use of the In the bonding method of the first substance of the present invention, there is an advantage in that a filamentary region is formed within a predetermined length along the optical axis direction of the laser beam, and the laser beam is obliquely incident on the bonding surface between the materials to be bonded, that is, the contact portion .

[0108] As mentioned above, in conventional ultrashort pulse laser beam welding, since it is necessary to accurately align the joint between the materials to be joined with the focal point of the laser beam, it is necessary to accura...

no. 3 Embodiment approach

[0115] In this embodiment, a description will be given of joining a substance made of a transparent material such as glass and a substance that reflects an ultrashort pulse laser beam, such as metal, using a nonlinear absorption phenomenon by an ultrashort pulse laser beam.

[0116] In the above-mentioned first and second embodiments of the method for joining substances of the present invention, it has been described that various substances can be joined by generating filamentous regions with an ultrashort pulse laser beam. Furthermore, it was discussed that since the filamentary region is formed over a predetermined length along the optical axis direction of the laser beam, it is a practically excellent joining method, which solves the problem of conventional ultrashort pulse laser beam welding, that is, continuous Difficulty in monitoring whether the focus of the laser beam is accurately formed at the interface of the materials to be joined.

[0117] On the other hand, accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com