Preparation method of stretched curd type mixed cheese and mixed cheese obtained thereby

A production method and cheese technology, applied in the field of food engineering, can solve the problems affecting the quality of cheese, the quality of cheese is not particularly ideal, the amount of soybean milk added is low, etc., and meet the requirements of improving health care function, being beneficial to digestion and absorption, production technology and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 , the preparation of soymilk

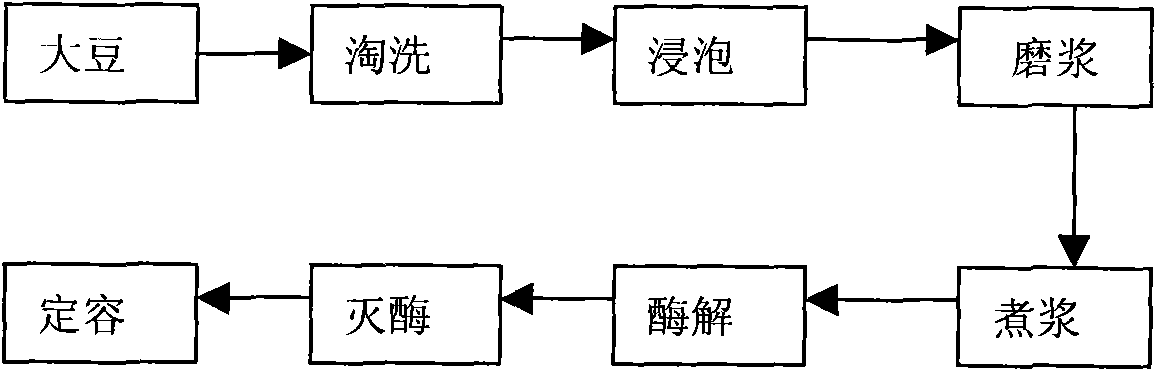

[0035] Such as figure 1 As shown, soybeans are firstly taken, rinsed and then soaked. In order to reduce the beany smell, baking soda is added at the same time in an amount of 0.25 to 0.5% of the total weight of the mixture.

[0036] Use a tissue masher, add 300ml of water per 100g of soybeans (after soaking), grind for 15s under the condition of 1000r / min, filter the ground soybean milk and heat at 90-95°C for 15min to remove trypsin Harmful factors such as enzyme inhibitors and further reduce the beany smell, then cool to room temperature, and then use cooled boiling water to dilute the soymilk to an appropriate soymilk volume. In this example, soymilk volume / soybean mass=7.0-8.0L / Kg (easily understood by those skilled in the art, other suitable ratios can also be used) for restriction enzymolysis;

[0037] The above-mentioned soymilk is first homogenized under the condition of 10-120MPa, preferably 20-70MPa, then the pH of...

Embodiment 2

[0041] Example 2 , Milk pretreatment

[0042] Requirements for raw milk: Hygienic inspection conforms to national standards, color and flavor are normal, and meets the basic requirements for cheese raw milk.

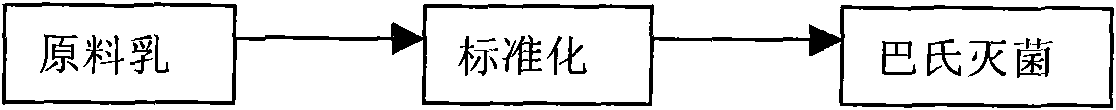

[0043] Such as figure 2 As shown, the raw milk is pretreated according to the conventional cheese making method, as follows:

[0044] First, the raw milk is centrifuged and then filtered to remove impurities in the milk, including somatic cells, some bacteria and some microbial spores;

[0045] Then the milk is standardized: the milk fat rate is adjusted to 3.0%, so that the ratio C of casein and fat: F=0.76;

[0046] The standardized milk is then sterilized (pasteurization: 63° C., 30 min).

Embodiment 3

[0047] Example 3 , Preparation of mixed milk

[0048] The enzymolyzed soybean milk obtained in Example 1 and the cow's milk obtained in Example 2 were mixed according to the ratio shown in Table 2 below, and then stirred evenly.

[0049] Table 2. Preparation of mixed milk

[0050] sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com