Method for making beehive paper board

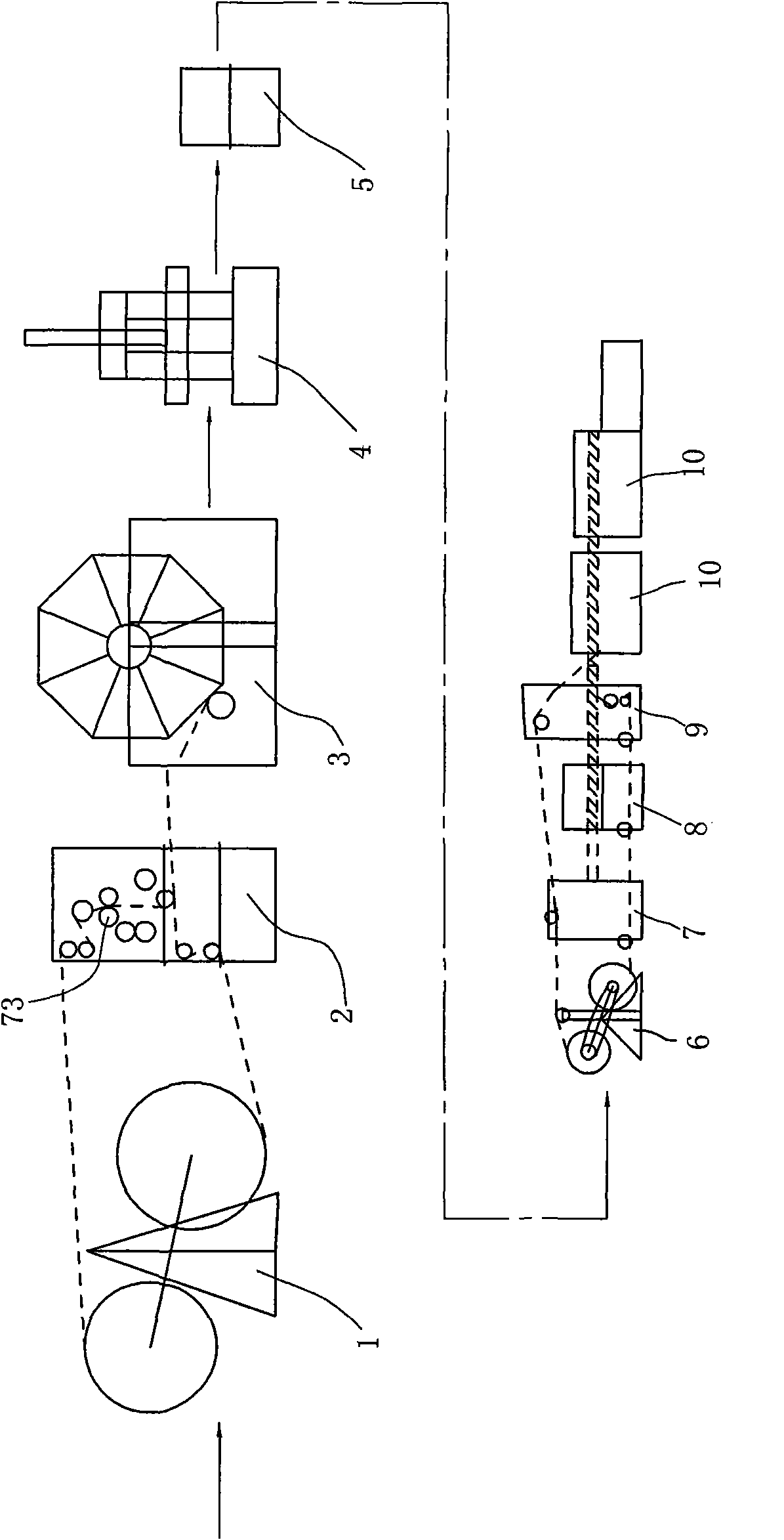

A manufacturing method and technology of honeycomb paperboard, applied in the direction of cardboard articles, chemical instruments and methods, laminating devices, etc., can solve problems such as the difficulty of manufacturing ultra-thin honeycomb paperboard, and achieve the effect of easy advancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

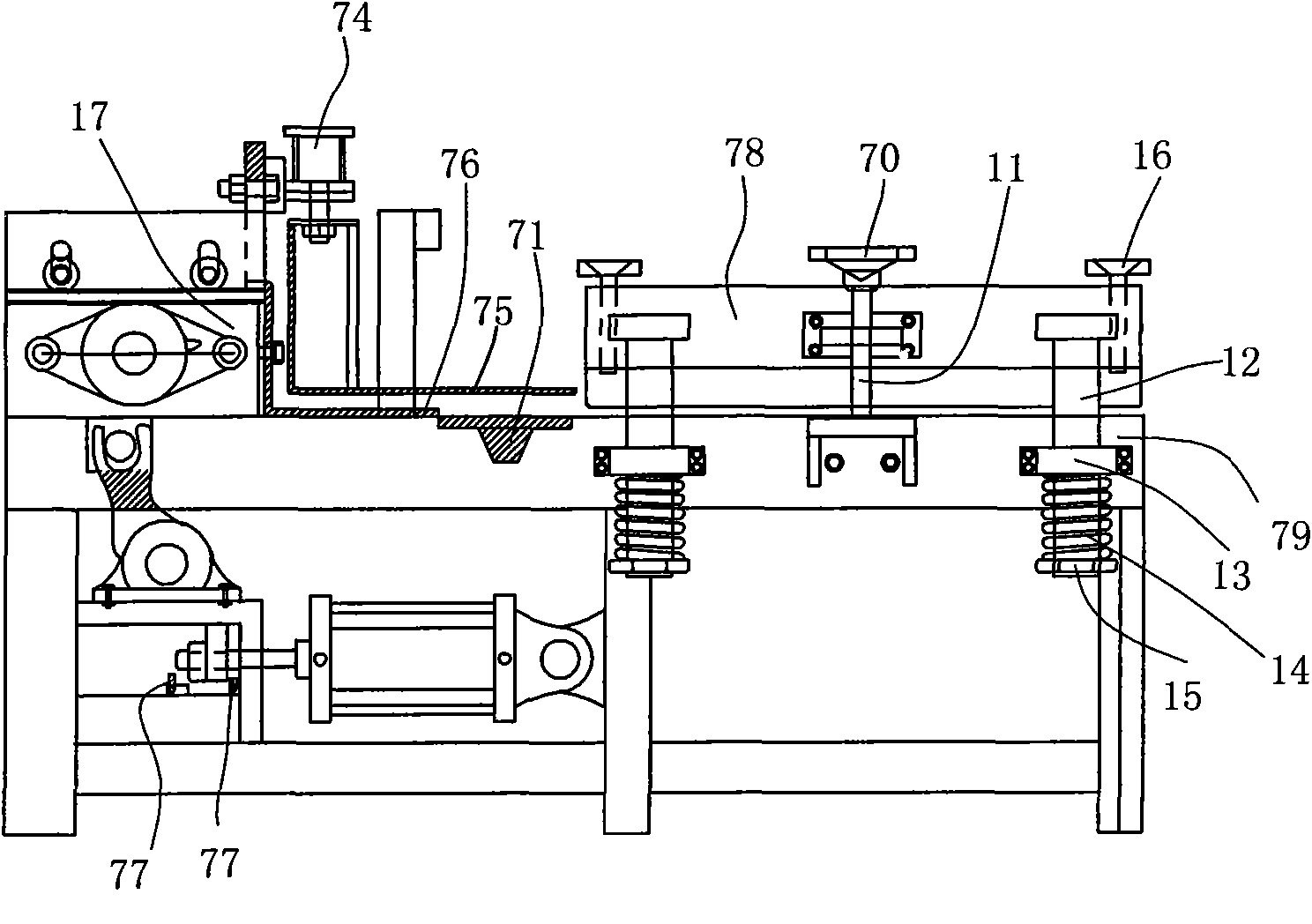

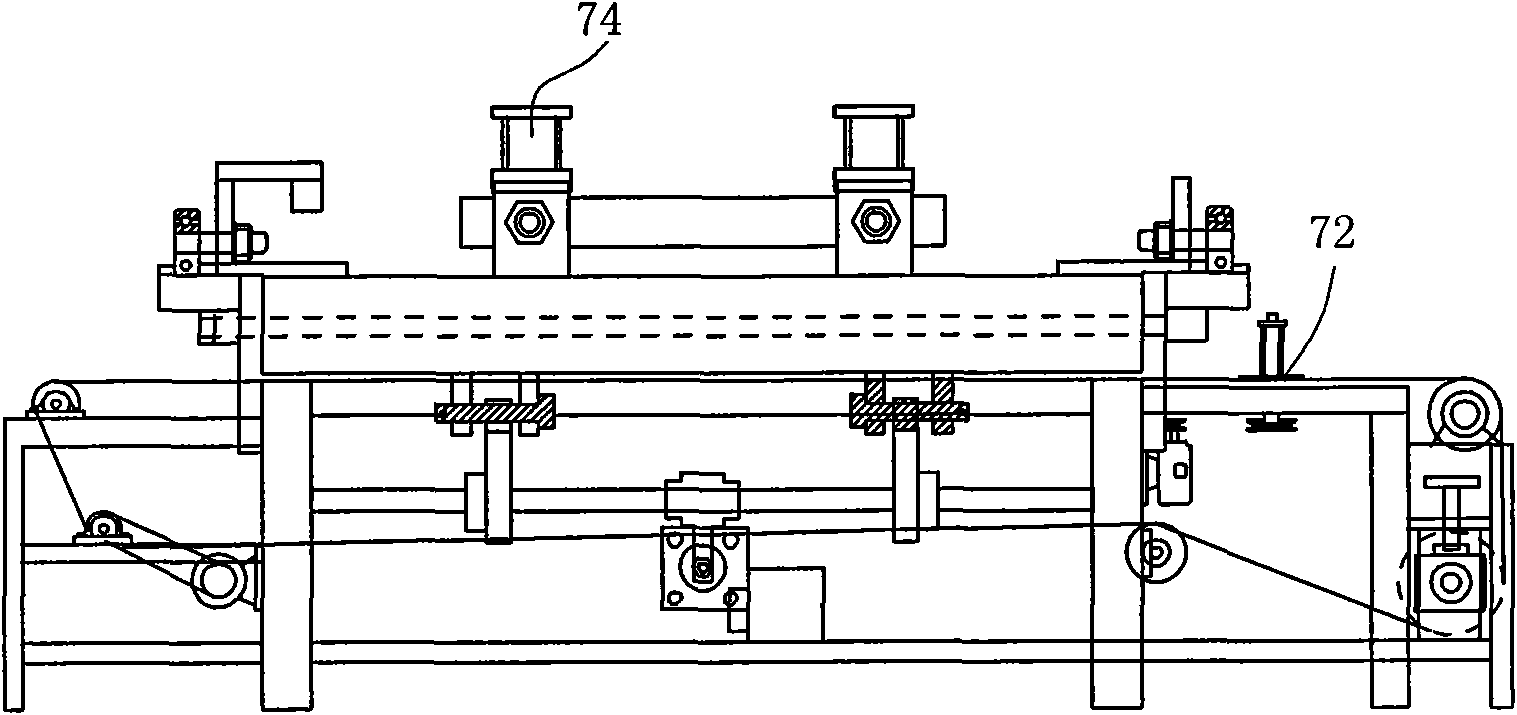

[0051] The present invention will be further described in detail below with reference to the embodiments of the drawings.

[0052] Such as figure 2 , image 3 with Figure 4 As shown, the butting machine for manufacturing honeycomb paperboard includes a worktable 79, a push plate 17 which is set at the back end of the worktable 79 and is driven by a push plate cylinder to reciprocate, and a push plate 17 is fixed on the front end of the push plate 17 17 A thin push plate 76 that moves together. In this embodiment, the longitudinal section of the thin push plate 76 is in the shape of a right angle "L", and its horizontal part rests on the table top of the worktable 79, that is, a flat plate used to push the cardboard forward. Push part; its vertical part is fixed on the front end surface of the push plate 17.

[0053] The upper part of the thin push plate 76 is provided with a push plate 75 that is driven by a driving mechanism and can reciprocate backward; the longitudinal sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com