Energy-saving air separation oxygenerator

An air separation and oxygen generation device technology, applied in the directions of oxygen preparation, climate sustainability, sustainable manufacturing/processing, etc., can solve problems such as energy waste in medical air separation and oxygen generation devices, and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

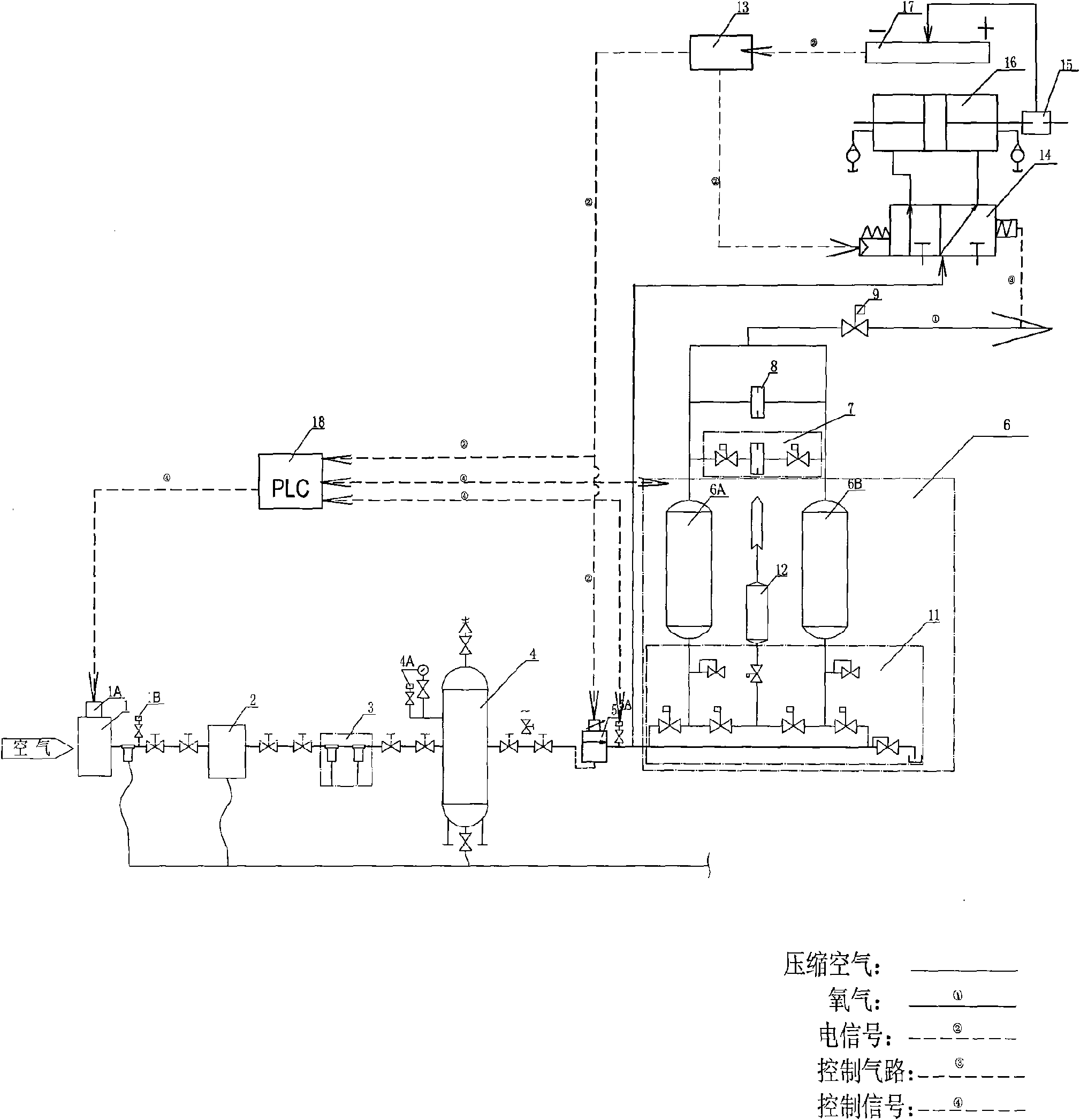

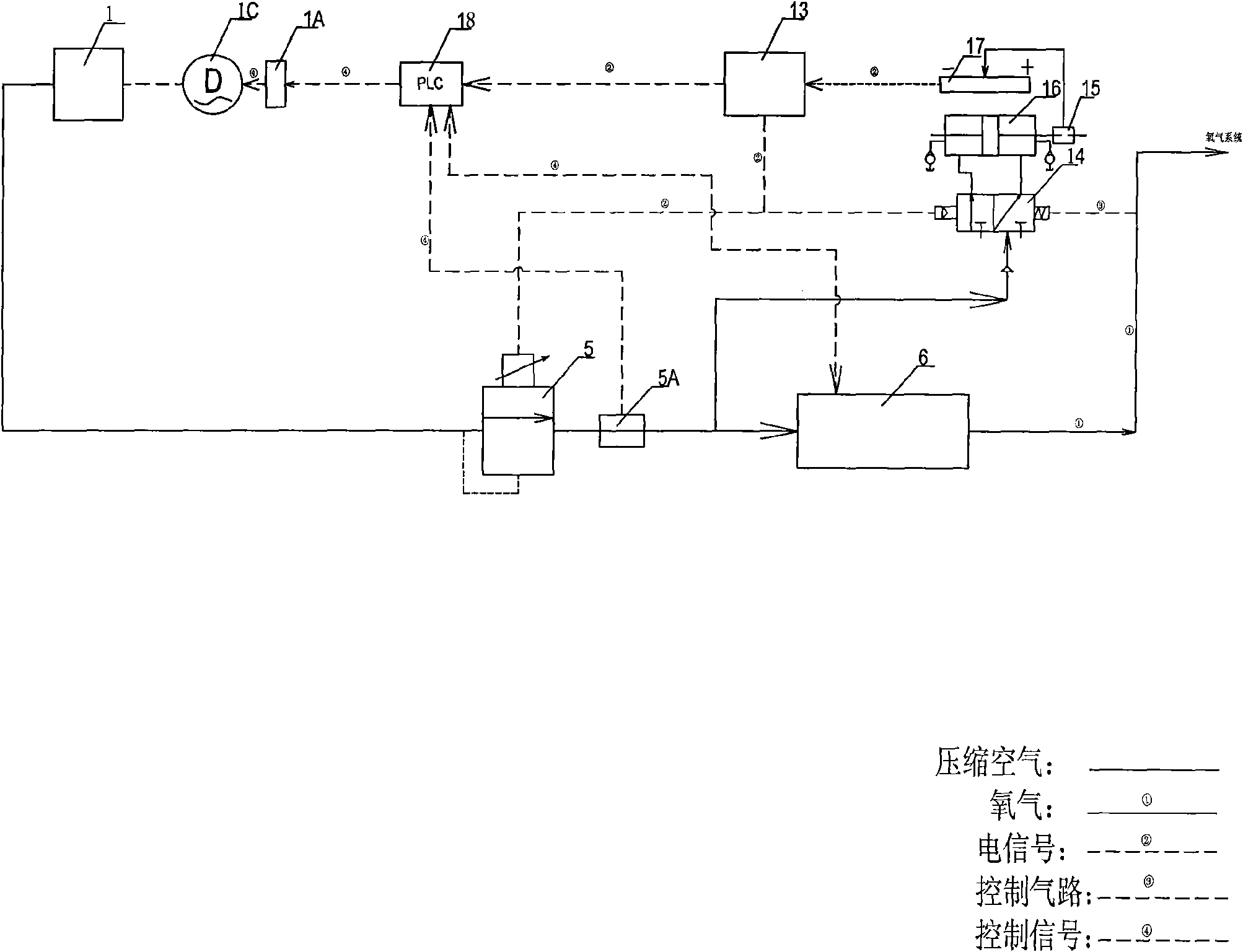

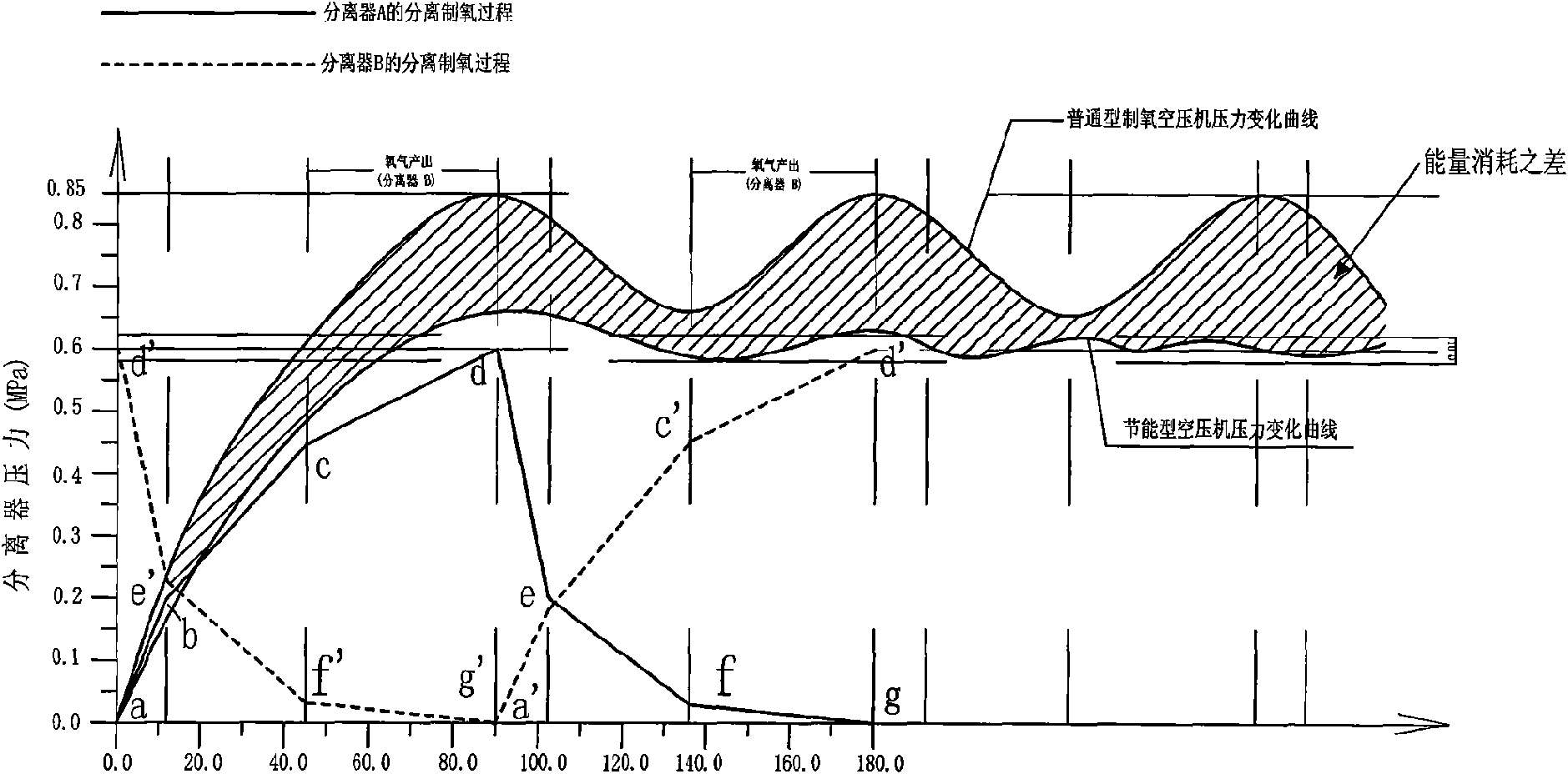

[0027] Such as figure 1 and figure 2 As shown, the energy-saving air separation oxygen production device of the present invention includes in sequence according to the oxygen production process: a frequency conversion air compressor 1, a pressure sensor 1B, a freeze dryer 2, an air filter 3, a pressure balance tank 4, an electric-air ratio regulator Pressure valve 5, pressure sensor 5A, separate oxygen generator 6, pressure balance regulator 7, flow controller 8 and oxygen automatic switch 9. In addition, it also includes a servo feedback device, which includes an electric-pneumatic control reversing valve 14, a servo cylinder 16, a displacement sensor 15, a feedback potentiometer 17, an amplifier 13, a frequency conversion regulator 1A, a pressure sensor 5A and a PLC programmable control Device 18.

[0028] The right end of the electric-pneumatic control reversing valve 14 is connected to the oxygen control pipeline drawn from the rear of the oxygen automatic switch 9, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com