Valve train without switch valve

A gas distribution mechanism and switching valve technology, applied to valve details, valve devices, mechanical equipment, etc., can solve problems such as difficult control, complex mechanism, and reduced intake pressure, and achieve high efficiency and precision, efficient and precise gas distribution, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

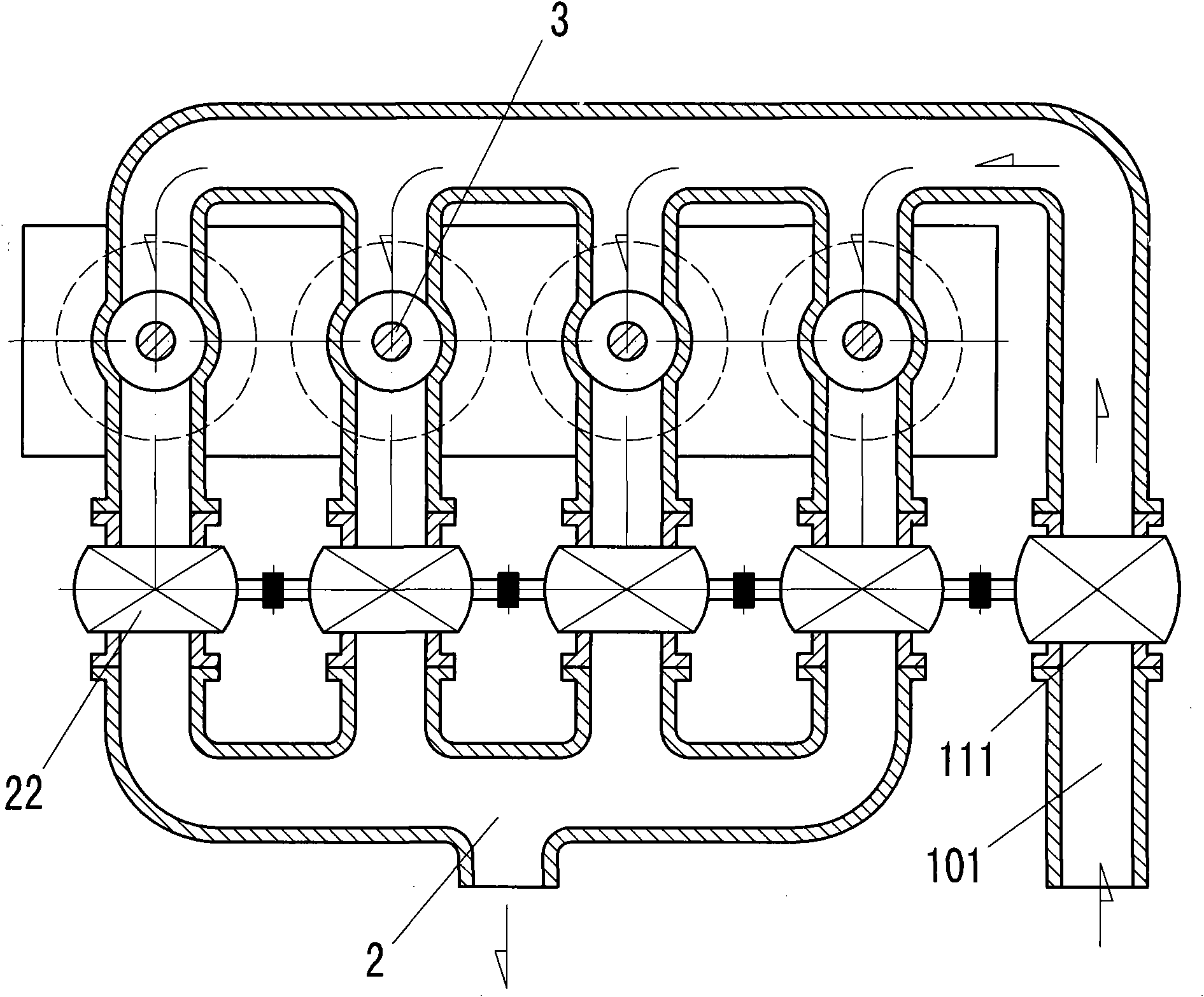

[0027] Figure number

[0028] 1. Intake duct 101. Intake duct combined 2. Exhaust duct 201. Exhaust duct integrated

[0029] 3. Front-mounted inner-opening shared valve for intake and exhaust 4. Control cam 5. Return spring

[0030] 45. Valve control system 6. Air seat port being assembled 11. Air intake compression device

[0031] 111. Total intake compression unit 22. Exhaust power unit 221. Total exhaust power unit

[0032] 66. Cylinder head 7. Power output shaft 8. Power input shaft

[0033] The present invention will be further described below in conjunction with accompanying drawing, please refer to figure 1 The air distribution mechanism without switching valve shown includes: intake port 1, exhaust port 2, positive assembly air seat port 6, cylinder head 66, in the cavity where the intake port 1 and exhaust port 2 communicate The axis of the positively assembled air seat port 6 is provided with the common valve 3 for the front-mounted internal drive and the row, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com