Projection-type high-power LED automobile dipped headlight and manufacturing technique thereof

An LED light source and high-power technology, which is applied in the field of projection-type high-power LED automotive low-beam lights, can solve the problems of high-power LED heat dissipation and power management that have not been broken through, industrialization has not yet been realized, and the structure is complex, etc., to achieve the benefit of lighting And high-speed driving, high luminous efficiency, uniform light source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

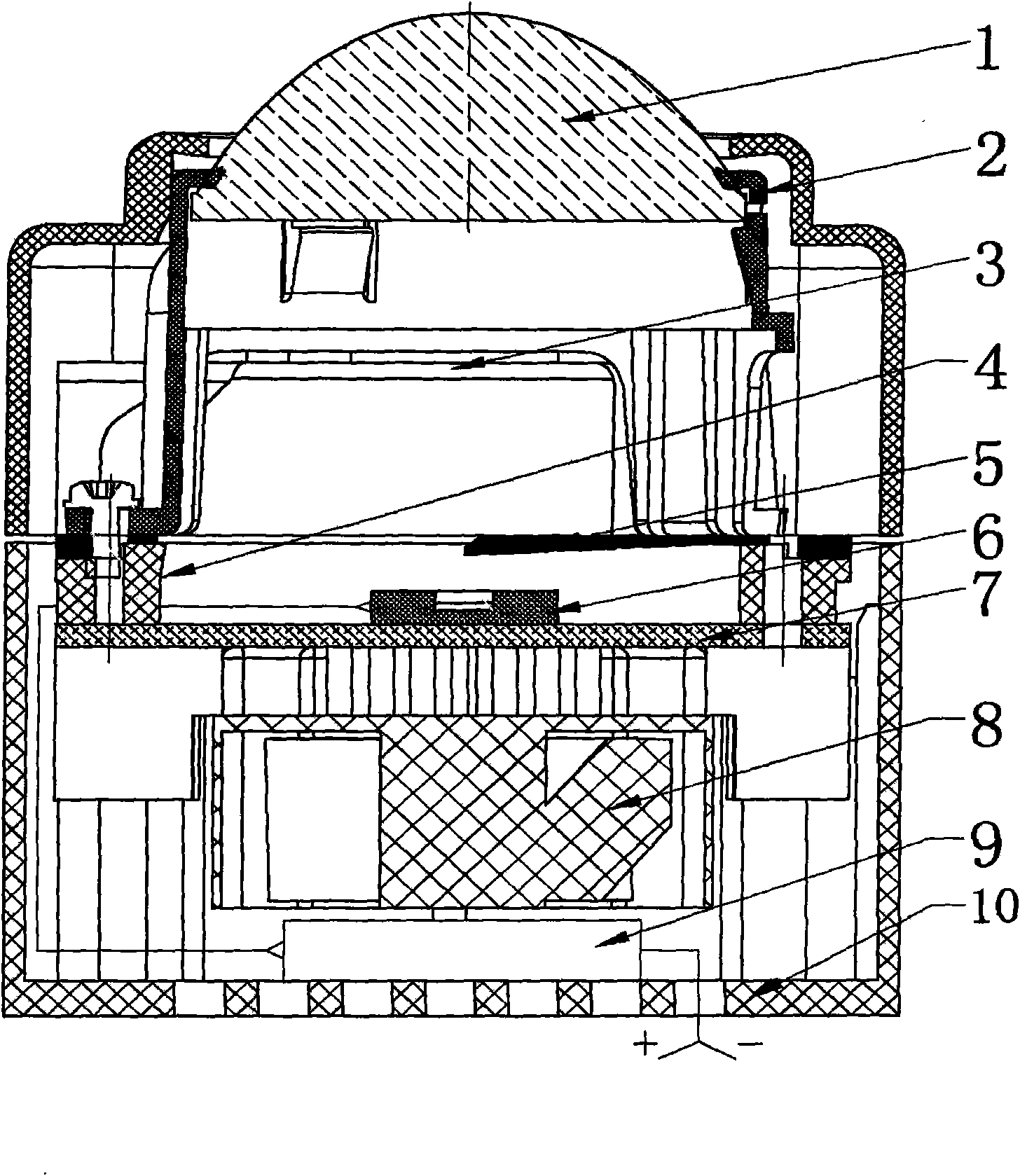

[0017] Known by Fig. 1, it is the projection type high-power LED automobile low beam lamp of the present embodiment, comprising optical lens 1, lens holder 2, LED light source 6, circuit control module 9 and lamp body 10, the bottom of described lamp body 10 A circuit control module 9 is provided, a light distribution forming plate 5 is provided in the middle, and an optical lens 1 is provided on the top. The bottom surface of the molding plate 5 is provided with a main reflection surface 4, and a sub-reflection surface 3 is provided on it. The cross-section of the light distribution molding plate 5 is a variable cross-section shape between the horizontal line and the 15-degree line, and the largest point of its cross-sectional size is between the horizontal line and the 15-degree line. point of intersection of the lines. The LED light source 6 is arranged on the top of the auxiliary radiator 7 . An auxiliary cooling fan 8 and a secondary radiator 7 are arranged above the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com