Visual detection method of ice coating thickness of overhead lines

A technology of ice coating thickness and visual detection, applied in the field of machine vision and power system online monitoring, can solve the problems of increasing workload, achieve low cost, realize automatic safety monitoring, and have great social significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 (single overhead wire)

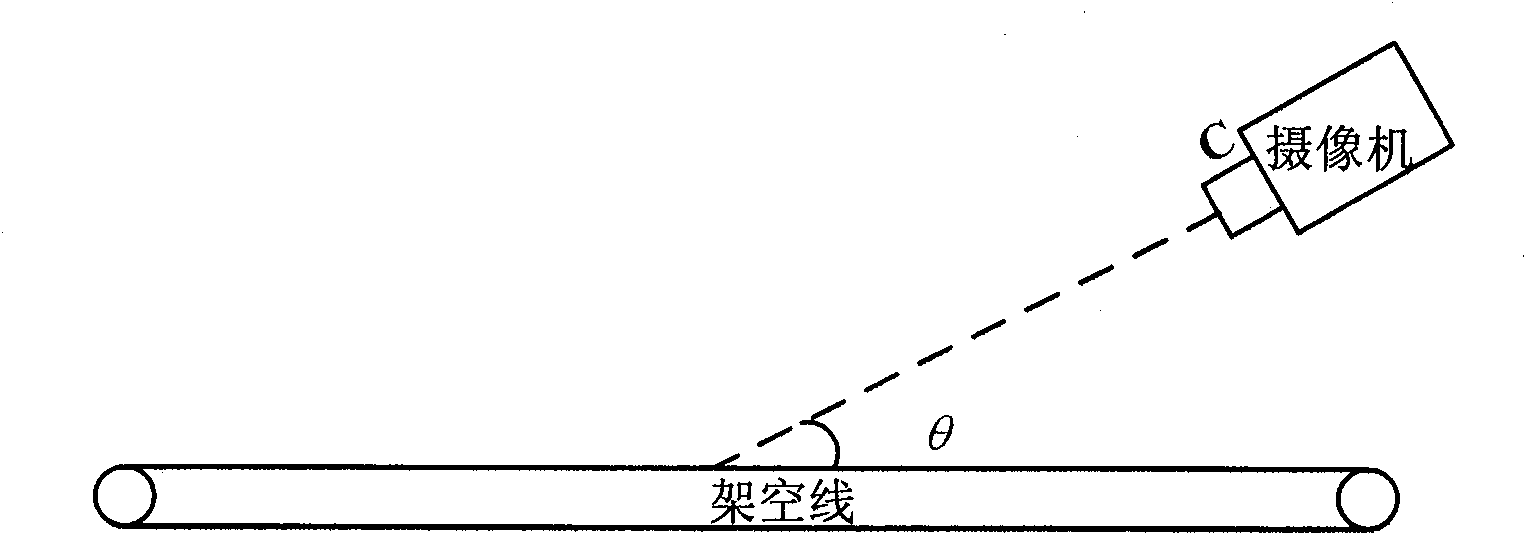

[0032] The present invention obtains the current image of the overhead line through a fixed-focus camera with a pan-tilt installed on the site iron tower or pole, and wirelessly transmits the image to the monitoring center through the GPRS network. Among them, the camera is installed above the overhead line, the optical center line of the camera is parallel to the projection of the overhead line in the horizontal plane, the optical center extension line of the camera and the projection of the overhead line in the horizontal plane form an angle of 30-60°, looking down on the overhead line, By adjusting the pan / tilt, the overhead line is basically in the middle of the imaging area of the camera, such as figure 1 shown.

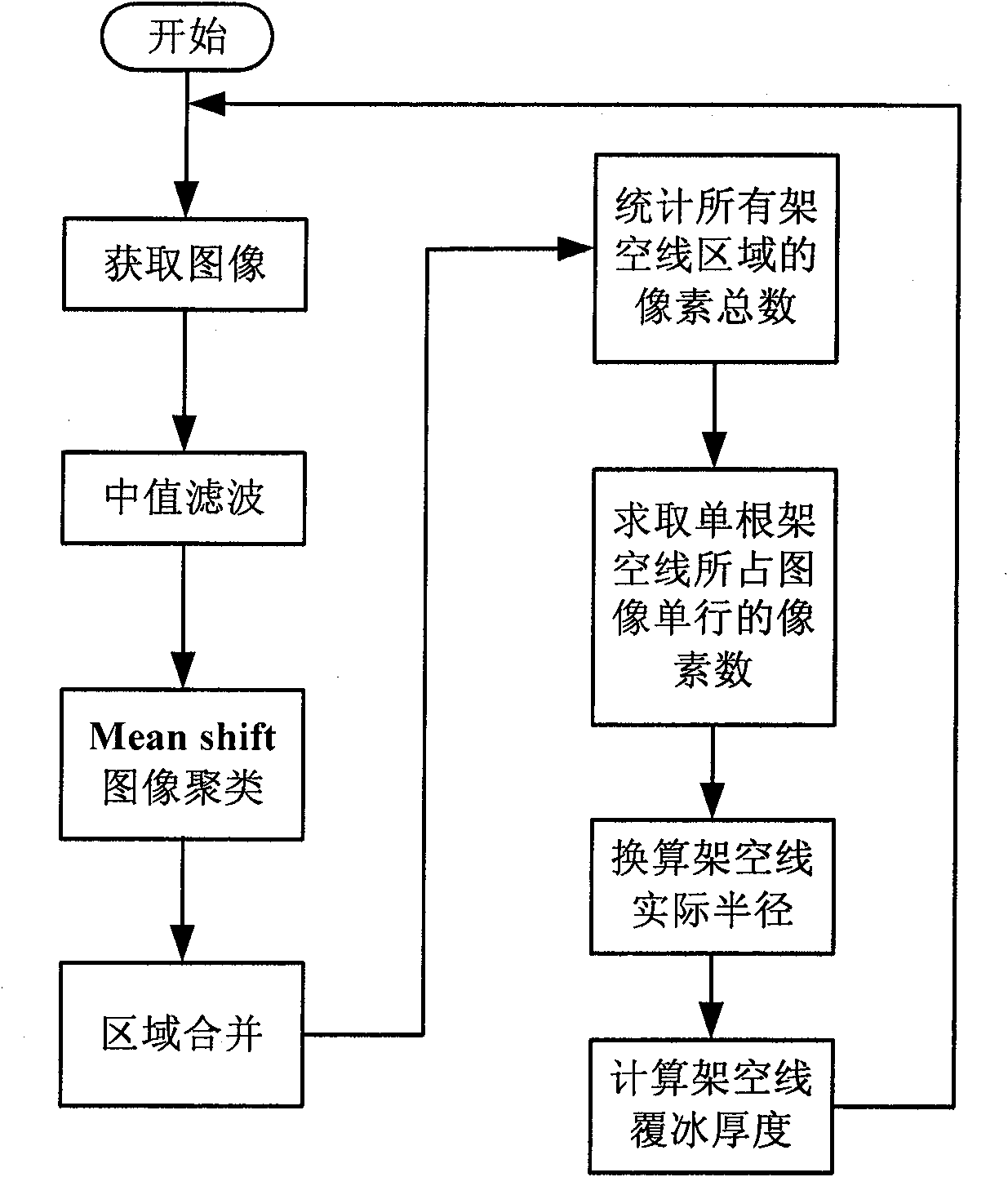

[0033] Then, after relevant processing of the acquired grayscale image, the ice thickness of the overhead line is calculated, and the steps are as follows:

[0034] 1. For the acquired overhead line grayscale imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com