Straw crusher used for whole-feed combine harvester

A technology of combine harvester and straw pulverizer, which is applied in the direction of harvester, agricultural machinery and equipment, application, etc., to achieve the effect of small vibration, ensure the quality of sowing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

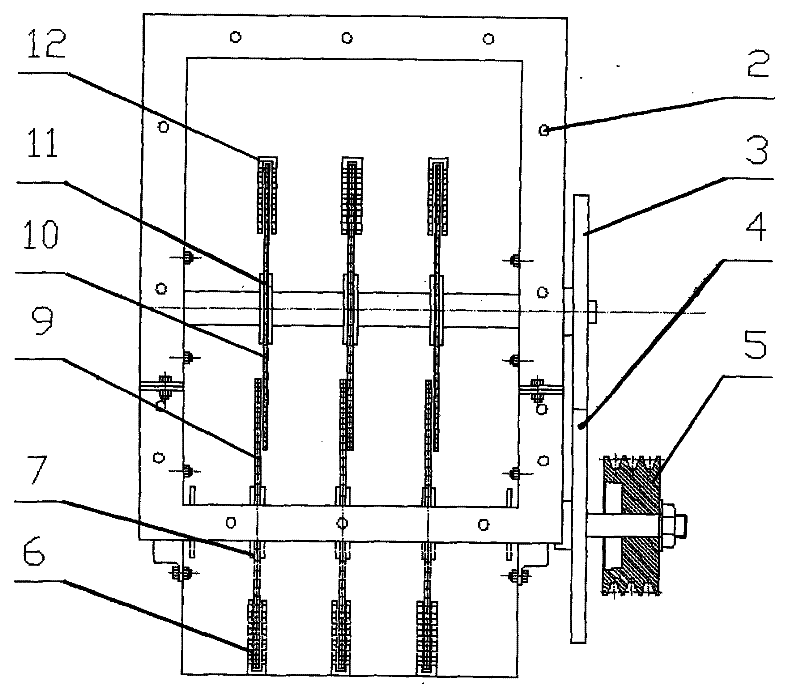

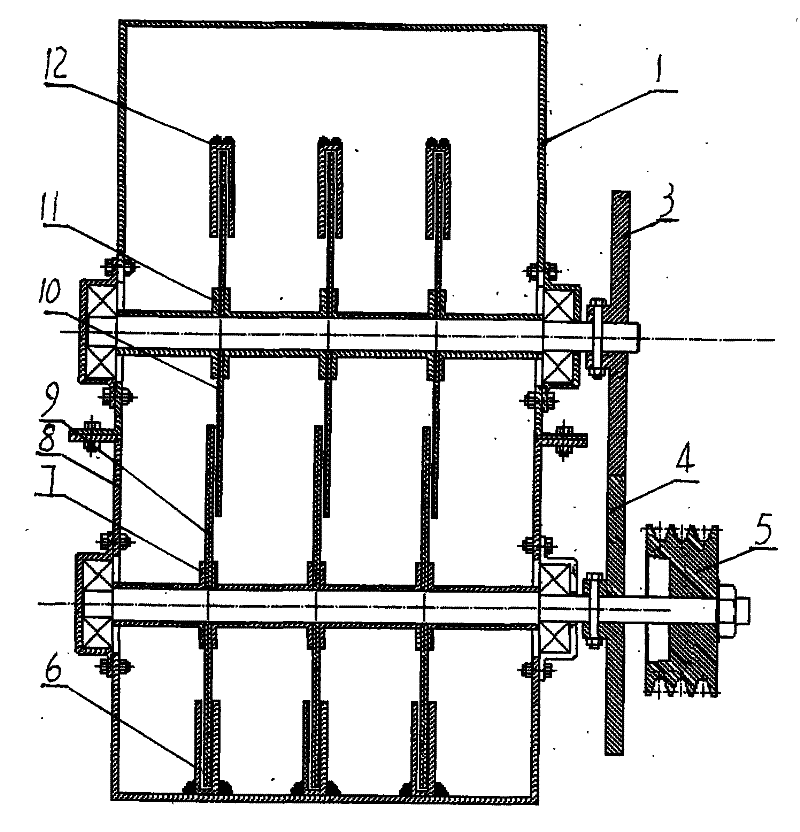

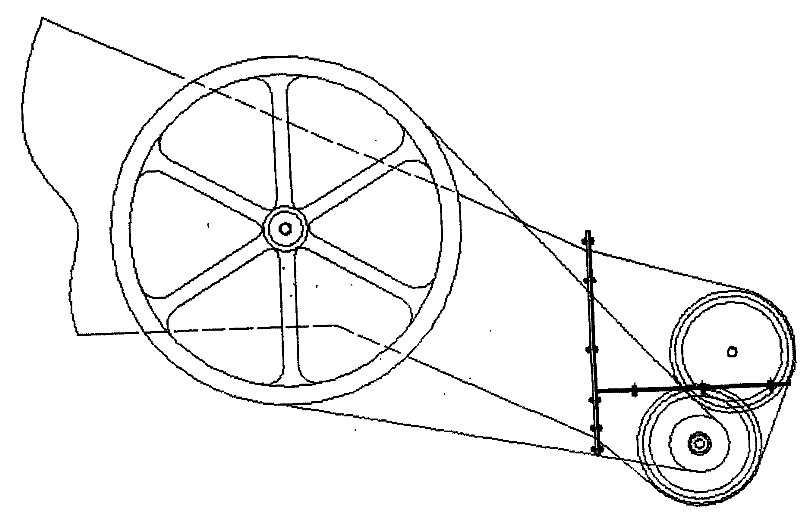

[0011] Such as figure 1 , 2 As shown, a straw pulverizer for a full-feed combine harvester includes a driven shaft and a driving shaft fixed at upper and lower intervals in a casing composed of an upper cover 1 and a lower cover 8, the driven shaft and the One group of saw blades 10,9 are fixed respectively by axle sleeves 11,7 on the driving shaft, and the driven gear 3 fixed on the shaft end of the driven shaft meshes with the driving gear 4 fixed on the shaft end of the driving shaft. The driven gear is equal in size to the driving gear, has the same rotational speed, and turns in the opposite direction. A group of saw blades respectively fixed on the driven shaft and the driving shaft are each composed of three saw blades, and the distance between adjacent saw blades in each group is 90mm.

[0012] The upper cover 1 of the casing is correspondingly fixed with the upper cutter teeth 12 matched with the three saw blade ends on the driven shaft, and the lower cover 8 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com