Methylbenzene recycling system

A recovery system and toluene technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of harmful operators, reduced adsorption capacity of activated carbon, and operation of hemp tops.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

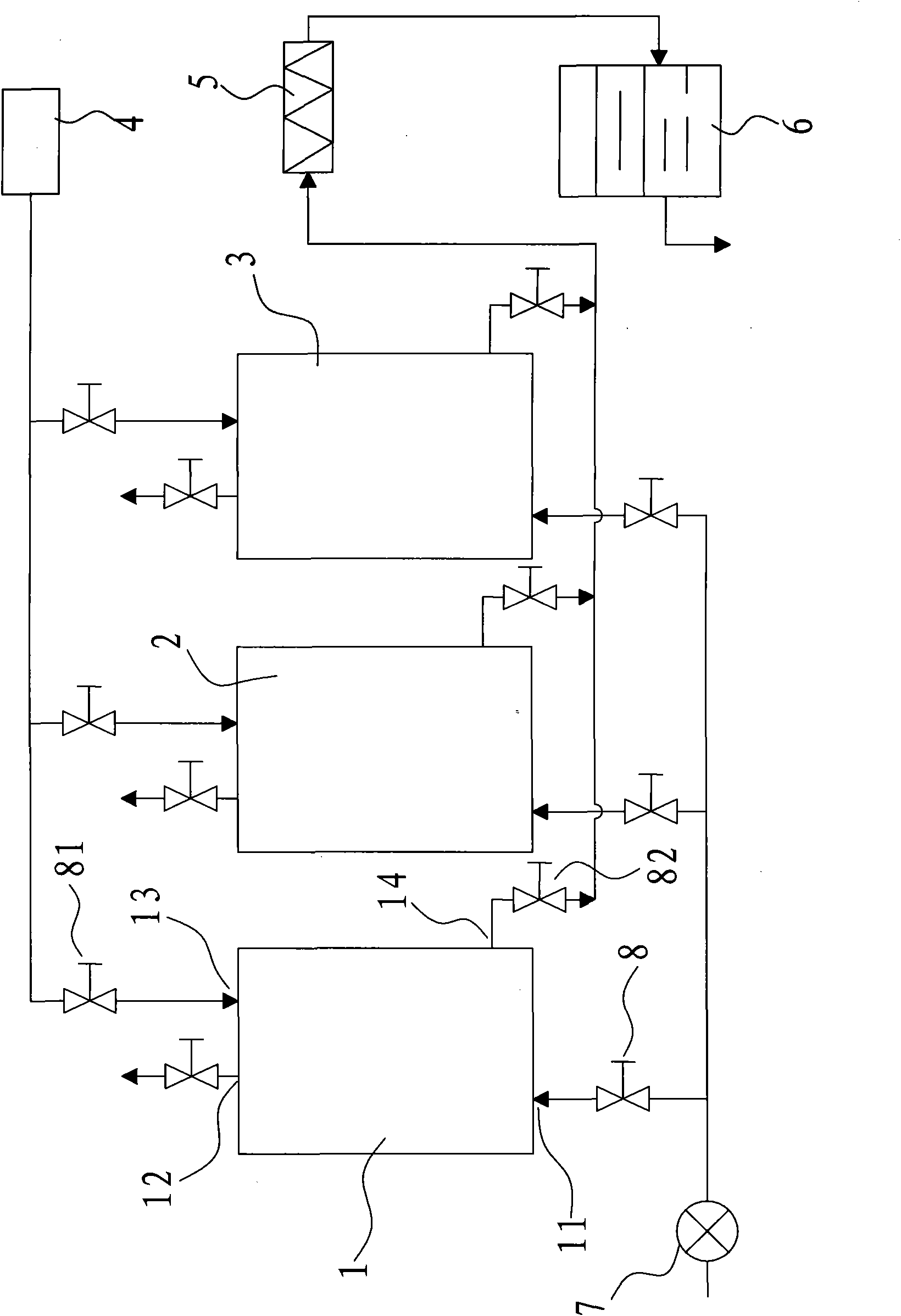

[0007] refer to figure 1 , the embodiment discloses a toluene recovery system, including an adsorption tank 1, an adsorption tank 2, an adsorption tank 3, a steam generator 4, a cooler 5, a separation box 6 and a fan 7, the adsorption tank 1 is a hollow structure and its The inner side is filled with activated carbon, and the adsorption tank 1 is respectively provided with an adsorption inlet 11, an adsorption exhaust port 12, a desorption steam inlet 13 and a desorption exhaust outlet 14. The structure of the adsorption tank 2 and the adsorption tank 3 Same as adsorption tank 1, the adsorption inlets of each adsorption tank are respectively connected to the air outlet of fan 7 through electromagnetic valve 8, the air inlet of fan 7 is connected to the exhaust gas collection port, and steam generator 4 generates steam by heating fresh water to each The adsorption tank provides high-temperature steam for desorption, and the exhaust port of the steam generator 4 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com