Hydrogen supply control device for hydrogen internal combustion engine

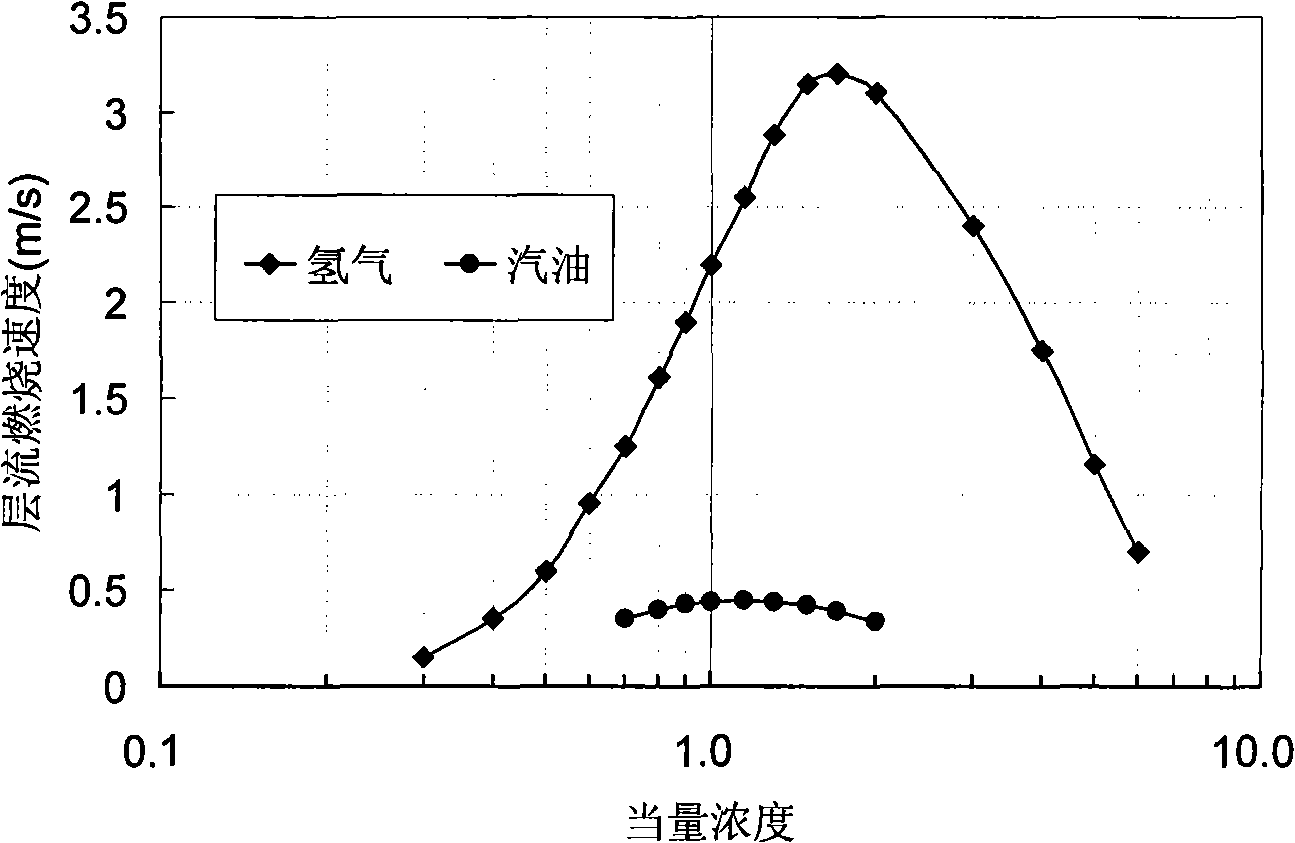

A technology for a hydrogen internal combustion engine and control equipment, which is applied in the field of an adaptive hydrogen supply pressure regulating device, can solve the problems of hydrogen engine power, rotational speed fluctuation, unstable nozzle operation, unstable idling hydrogen injection, and insufficient high-speed power and torque output. , to achieve the effect of reducing NOx emissions, significant practical value, and satisfying stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

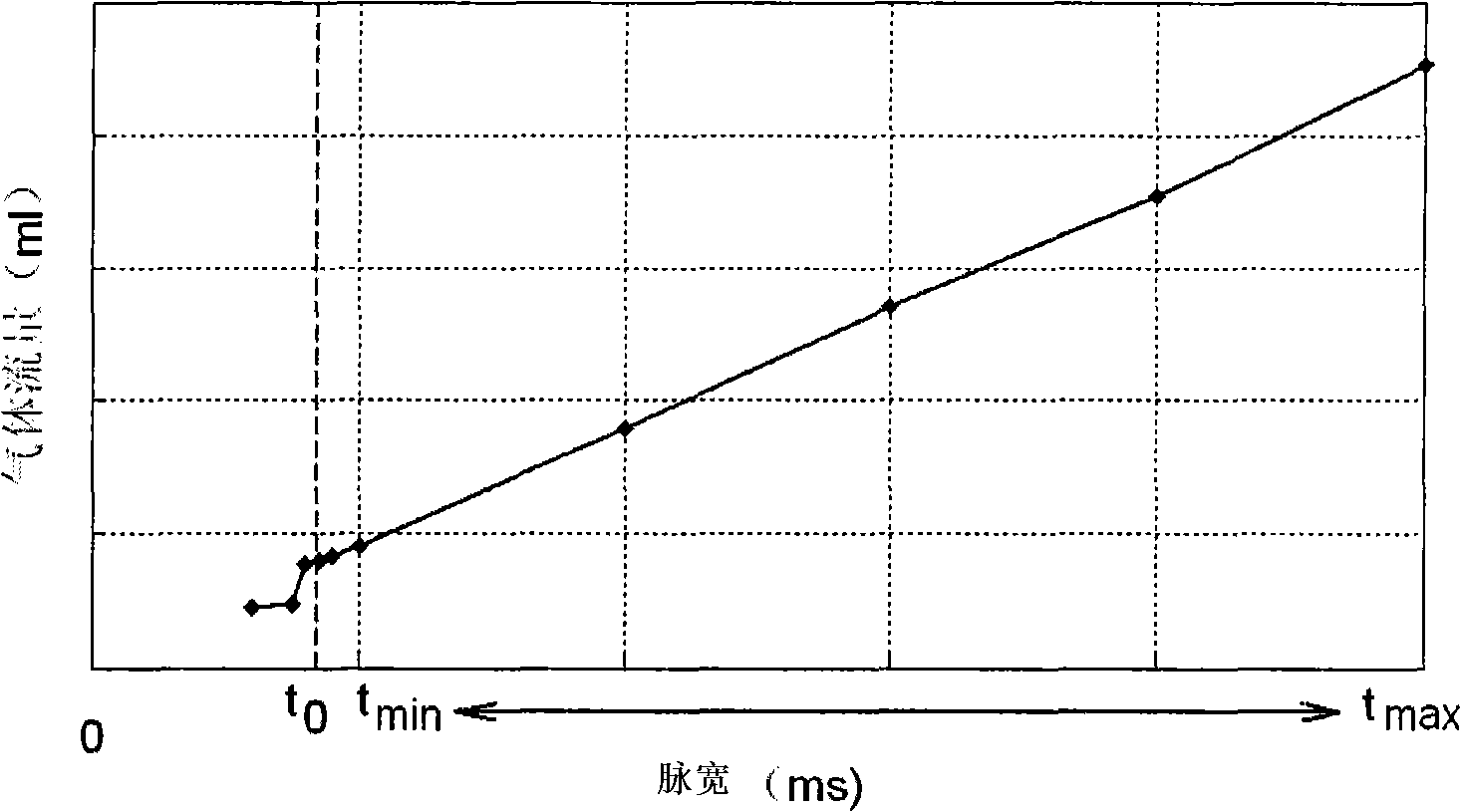

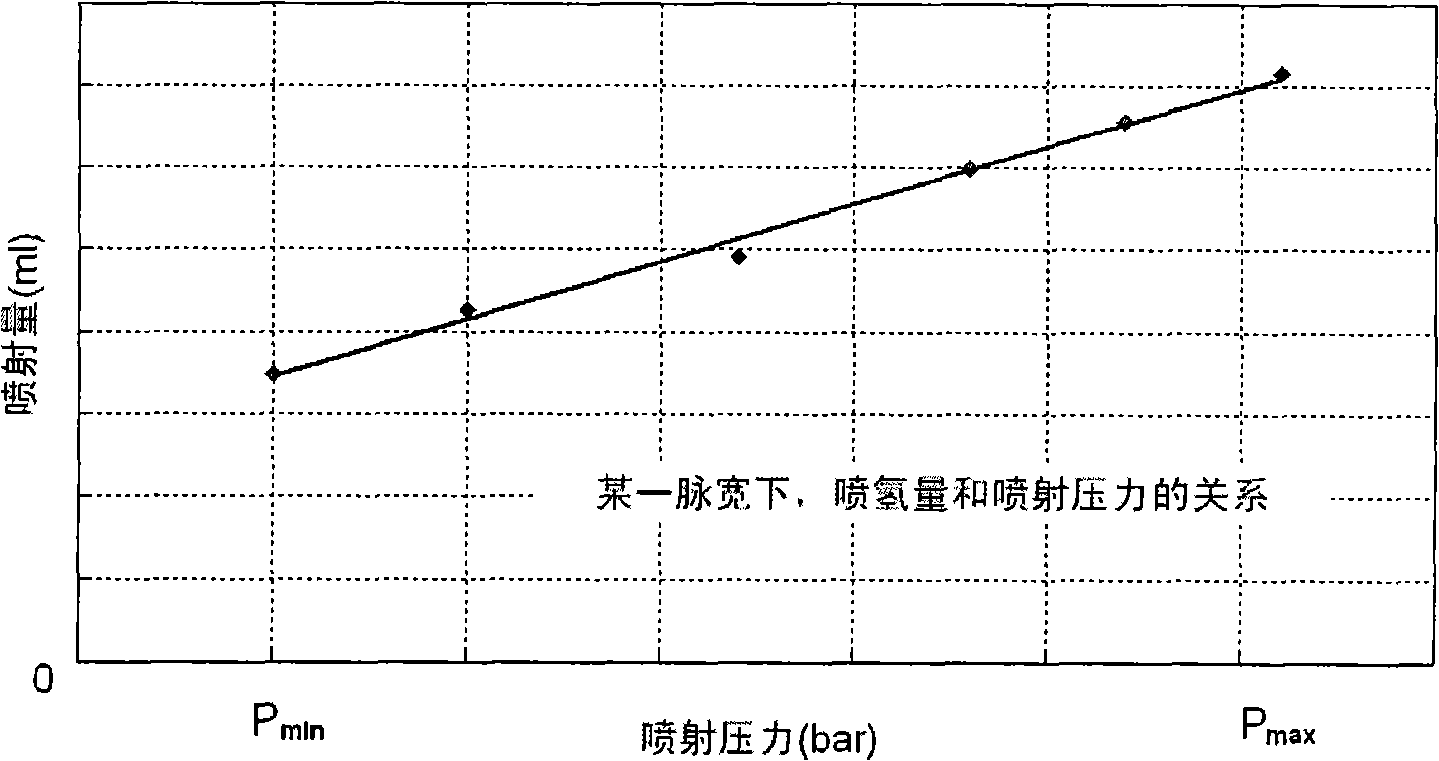

Method used

Image

Examples

Embodiment Construction

[0019] Figure 5 An adaptive hydrogen supply system for a hydrogen engine according to an embodiment of the present invention is shown. The system includes a hydrogen cylinder 1 that stores hydrogen. The hydrogen from the hydrogen cylinder 1 reaches the first-stage pressure reducing valve 3 through an electric shut-off valve 2, After the first-stage decompression, the hydrogen pressure is generally about 5-8bar, and then the hydrogen after the first-stage decompression reaches the electronically controlled pressure regulating valve 4. The electronic control unit (ECU) 11 and the electronically controlled pressure regulating valve 4 are kept electrically connected for electrical The pressure regulating valve 4 performs control, so that the ideal pressure hydrogen output from the pressure regulating valve flows into the hydrogen regulator rail 8 through the flame arrestor 5 and finally reaches the front end of the hydrogen nozzle 9, and finally the nozzle sprays hydrogen according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com