Apparatus for controlling discharge of hydrogen internal combustion engine by thermal exhaust recirculation

A technology of exhaust gas recirculation and exhaust gas recirculation valve, applied in the direction of exhaust gas recirculation, internal combustion piston engine, combustion engine, etc., can solve the problems of engine oil deterioration, water condensation, complex engine system, etc., achieve low NOx emissions, simplify Control system, the effect of meeting the requirements of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

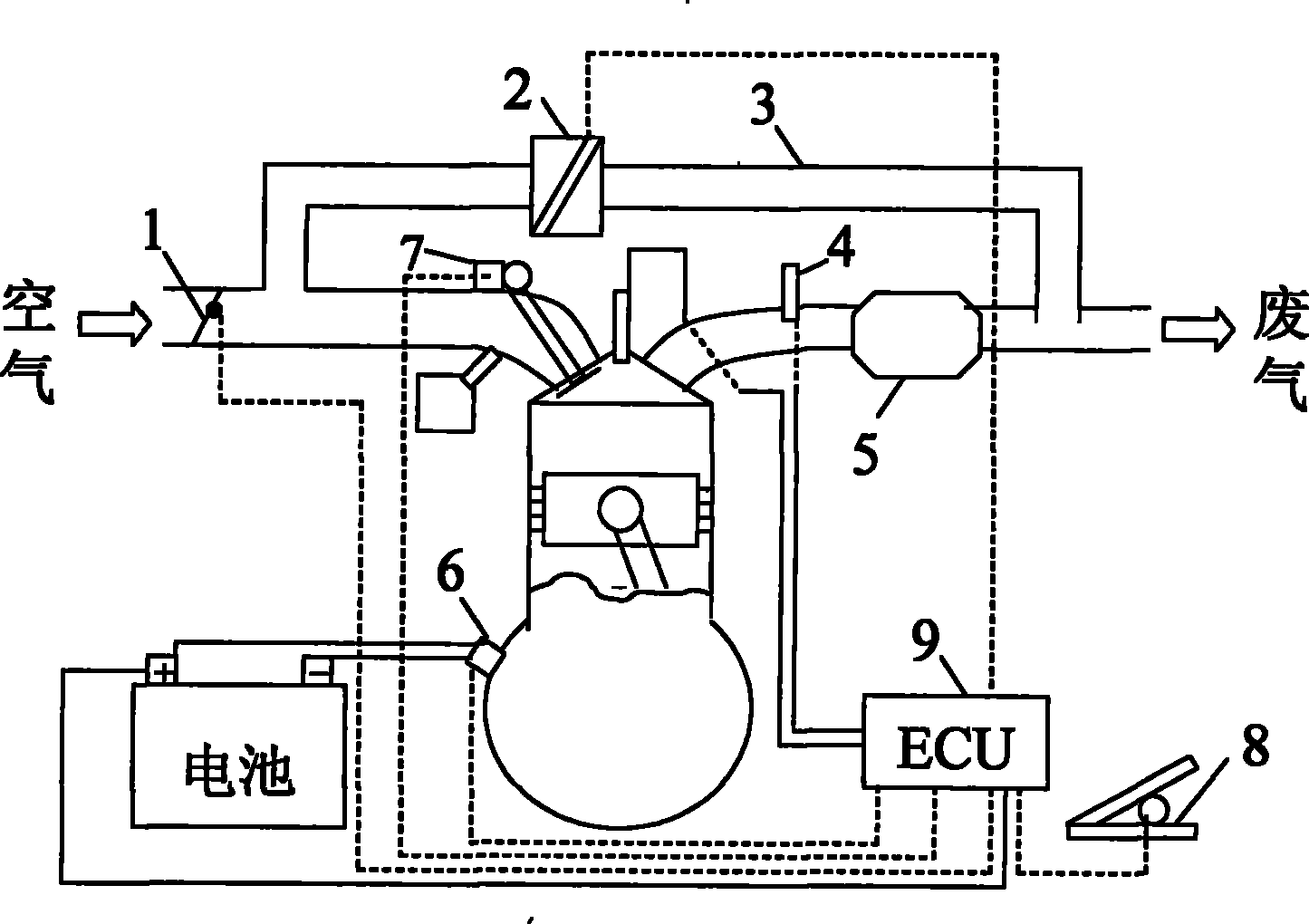

[0024] Such as figure 1 As shown, a hydrogen internal combustion engine hot exhaust gas recirculation system according to a preferred embodiment of the present invention includes: an electronic throttle valve 1 installed on the intake pipe, a camshaft position sensor 7 on the cylinder head, and a crankshaft position on the engine body The sensor 6, the exhaust oxygen concentration sensor 4 installed on the gas collecting cavity of the exhaust pipe, the three-way catalyst 5 connected with the exhaust pipe, and the exhaust gas recirculation pipe 3 leading from the exhaust manifold are connected to the exhaust pipe. An electronically controlled EGR valve 2 is installed on the air and intake recirculation pipeline 3 to control the flow of the recirculated exhaust gas. The throttle position sensor 8 provides the driver's demand signal and the engine control unit 9.

[0025] The exhaust gas recirculation pipe 3 introduces the exhaust gas discharged from the engine into the intake pipe. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com