Screw thread shearing type collision energy-absorbing device for vehicles

A collision energy-absorbing and shearing technology, which is applied in the field of vehicle engineering, can solve the problems such as the inability of the impact screw to expand, the initial collision acceleration is large, the initial acceleration is reduced, etc., to achieve stable safety protection, stable stress deformation characteristics, Vibration and noise reduction effect

Inactive Publication Date: 2011-01-05

CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it directly uses the external thread on the threaded rod to impact the internal thread on the threaded sleeve. Since the engagement between the threaded rod and the threaded sleeve is two or more turns, the initial thread breaking force is the force of breaking one circle of thread. twice or more than that of , and it is the impact of surface-to-surface contact. Therefore, in the initial stage of the collision, an initial force much greater than the force of breaking a circle of thread is required to break the thread. This makes the initial collision acceleration huge. When the car collides at high speed , the driver and occupant cannot withstand the huge deceleration process and cause life-threatening

The invention patent with the patent number ZL200710034933.2 discloses an adaptive impact energy absorbing device. This invention overcomes the shortcomings of the "thread shear type automobile collision energy absorbing device". The impact screw is threaded with a nut to avoid Directly use the external thread on the impact screw to impact the internal thread on the threaded sleeve to ensure that the device only needs to break a circle of thread force at the initial stage of the collision to start the device, so that the initial acceleration during the collision is reduced, and when the car collides at high speed , the deceleration process is stable, which is beneficial to protect the life safety of the occupants, but the telescopic power source of this invention is a motor installed on the bumper. When the impact screw expands and contracts, under the action of its own weight, the meshing area between the nut and the impact screw A huge bending moment will be generated, which may cause the impact screw to be unable to expand and contract or require too much power

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

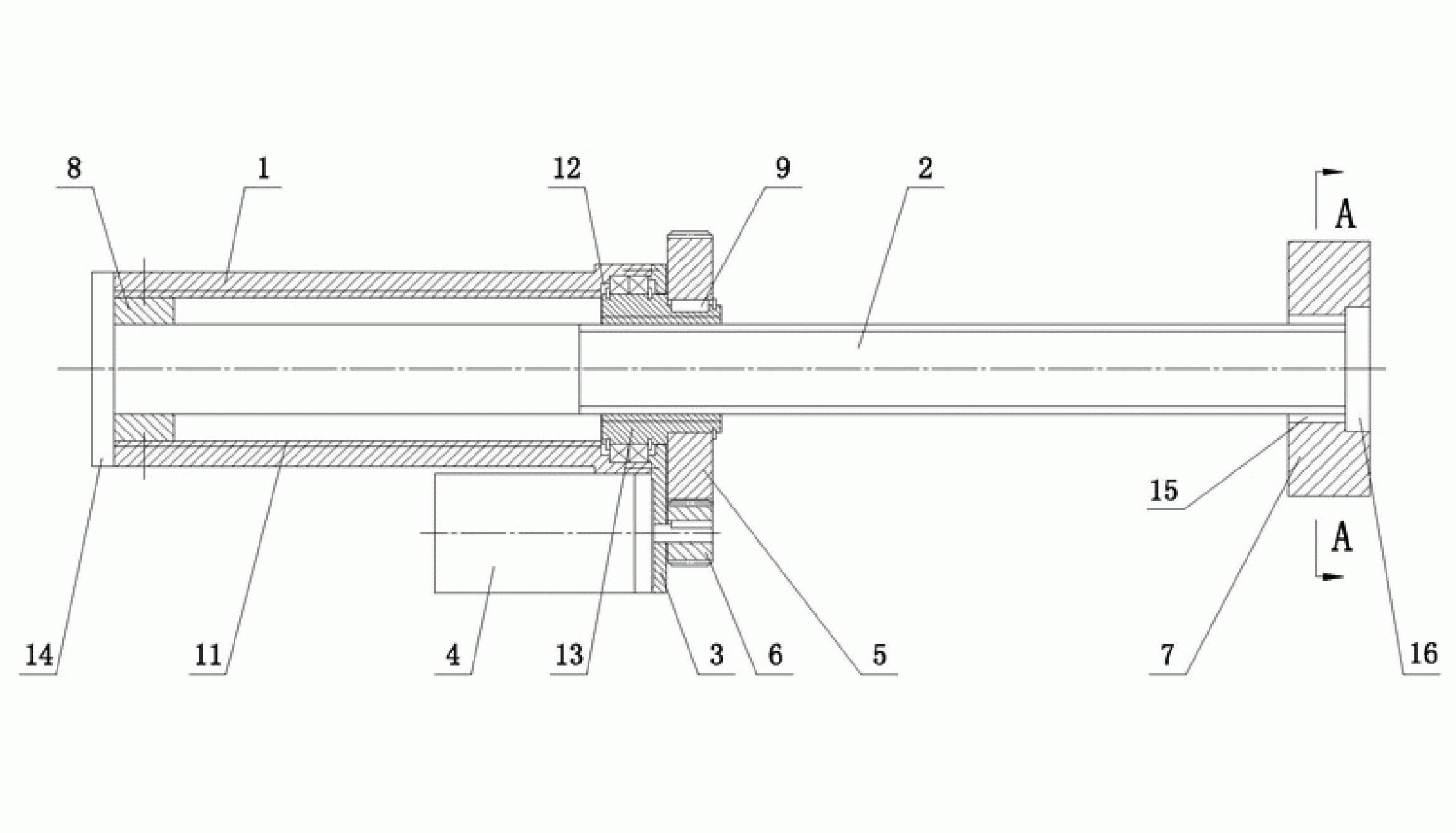

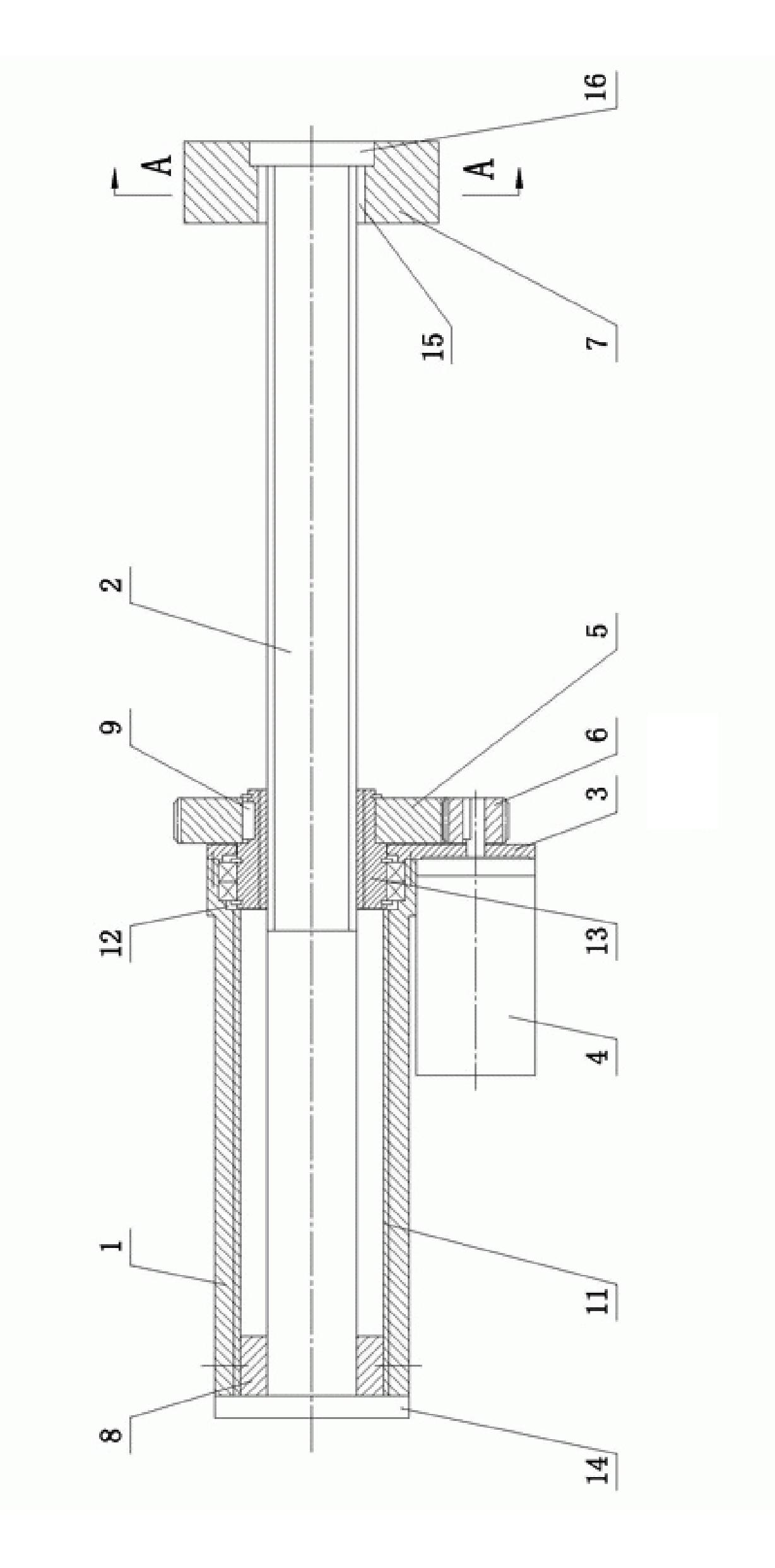

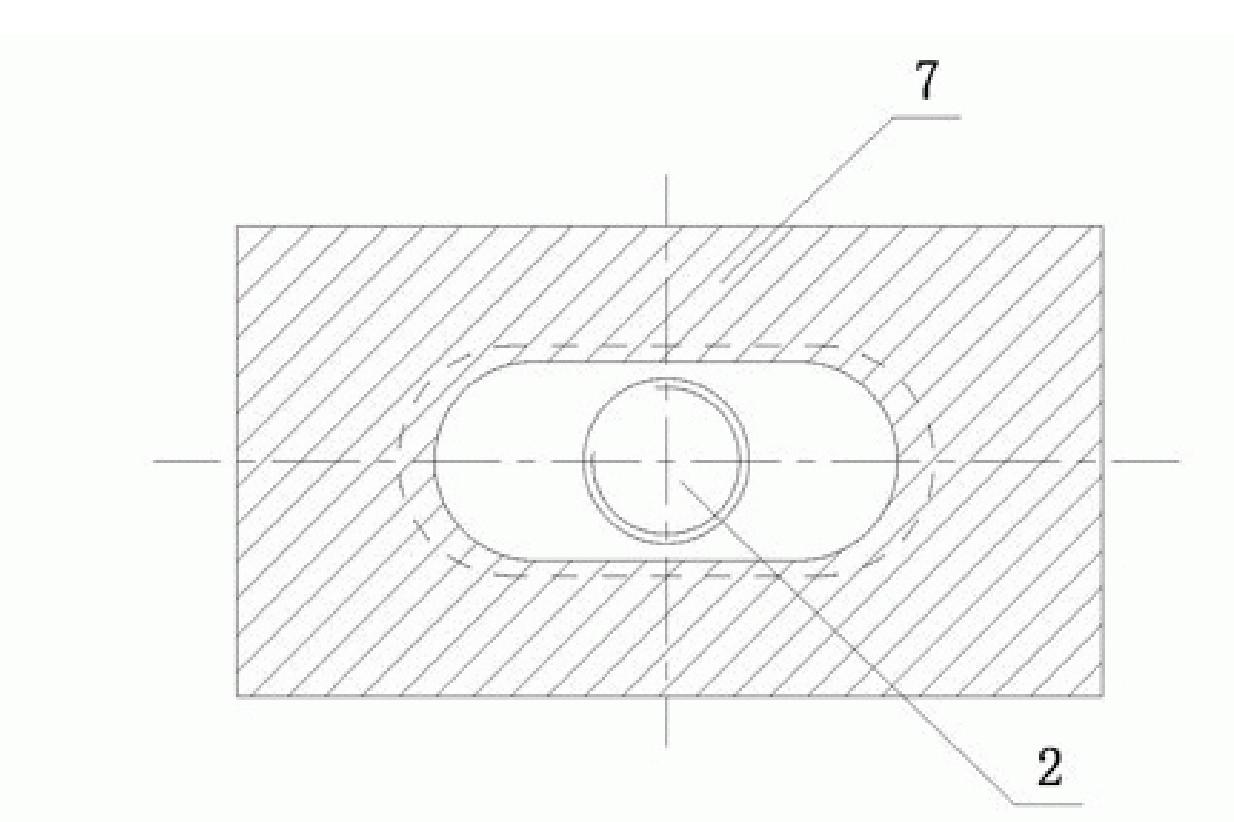

The invention discloses a screw thread shearing type collision energy-absorbing device for vehicles, comprising a threaded sleeve, an impacting screw rod and a nut. One end inside the threaded sleeve is an inner screw thread section and the other section is a through hole section. One end of the impacting screw rod is sleeved in the threaded sleeve and the other end extends out of the threaded sleeve. The nut is sleeved on the impacting screw rod by the screws. The external diameter of the nut is larger than the interior diameter of the inner screw thread section. One end of the nut is supported in the through hole section by a bearing and the other end extends out of the threaded sleeve. The threaded sleeve is provided with a drive motor aside fixed on the vehicle body member. The drive end of the drive motor is connected with the nut via a transmission mechanism. The screw thread shearing type collision energy-absorbing device for vehicles has simple structure, wide applicability andensures the impacting screw rod freely contracts according to the expected requirement.

Description

Screw shear type crash energy absorbing device for vehicles technical field The invention relates to the field of vehicle engineering, in particular to a thread shear type collision energy-absorbing device for vehicles. Background technique The impact energy absorbing device is widely used in the safety design technology of automobiles. The traditional impact energy absorbing device adopts the crushing energy-absorbing mechanism. The metal deforms and buckles to absorb the impact energy. This kind of structure does not have very high requirements on the layout type, but the collision energy absorption capacity can only be pre-designed and cannot be adjusted; after the collision, it will cause a large area of deformation of the vehicle body, and the maintenance cost is high. The invention patent with the patent number ZL03124568.4 discloses a thread shear type automobile collision energy absorbing device, which utilizes the characteristic that the shear destructive forc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B60R19/18

Inventor 雷正保

Owner CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com