Method and device for conveying collection strip of multiway plume

A conveying device and technology for tobacco rods, which are applied in the multi-channel tobacco-rod collection and arrangement conveying system, logistics conveying device, multi-channel tobacco-rod collection, arrangement and transportation fields, can solve the problem of crowded packaging area, occupied space, huge size, etc. and other problems, to achieve the effect of smooth and smooth operation, easy maintenance and improved conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

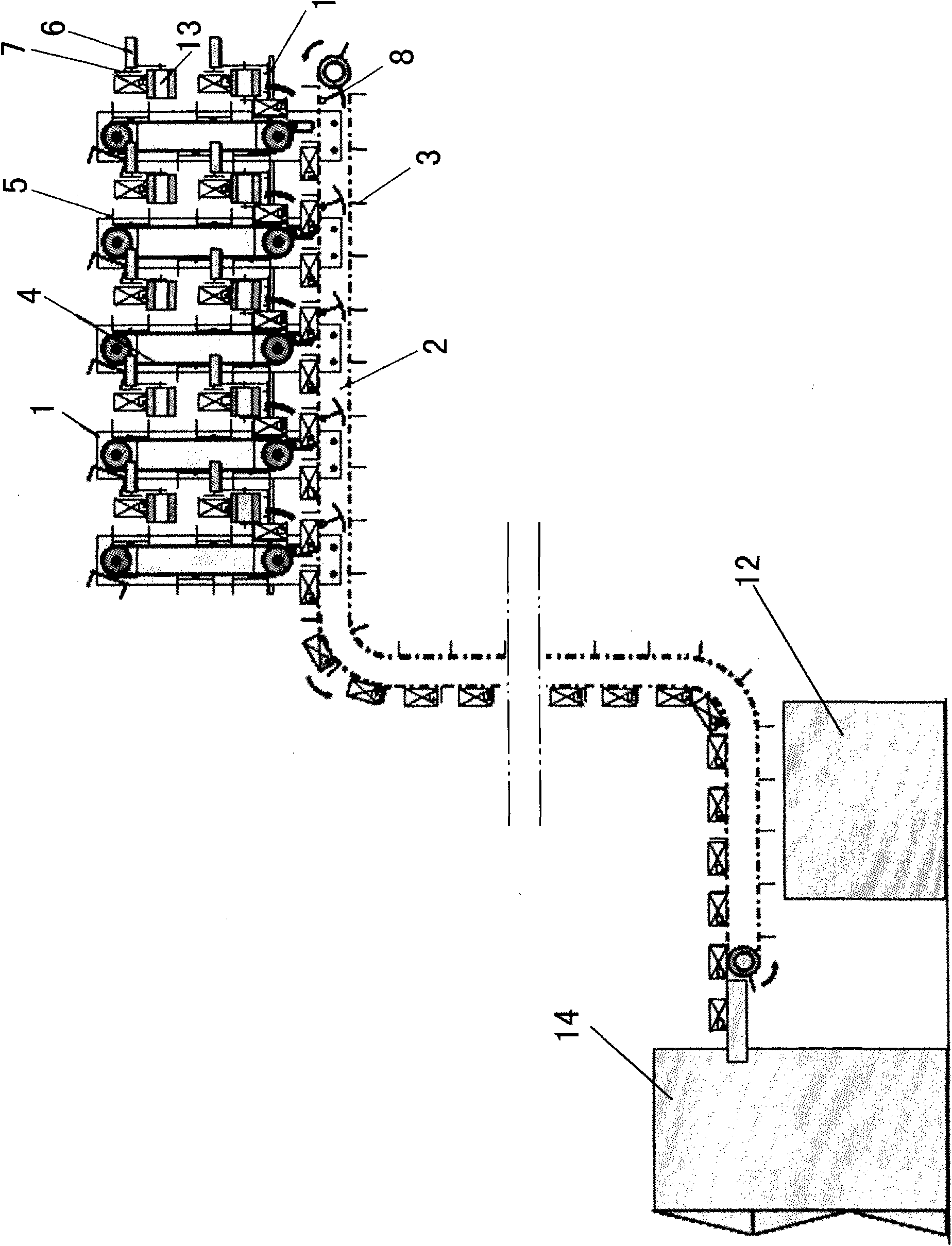

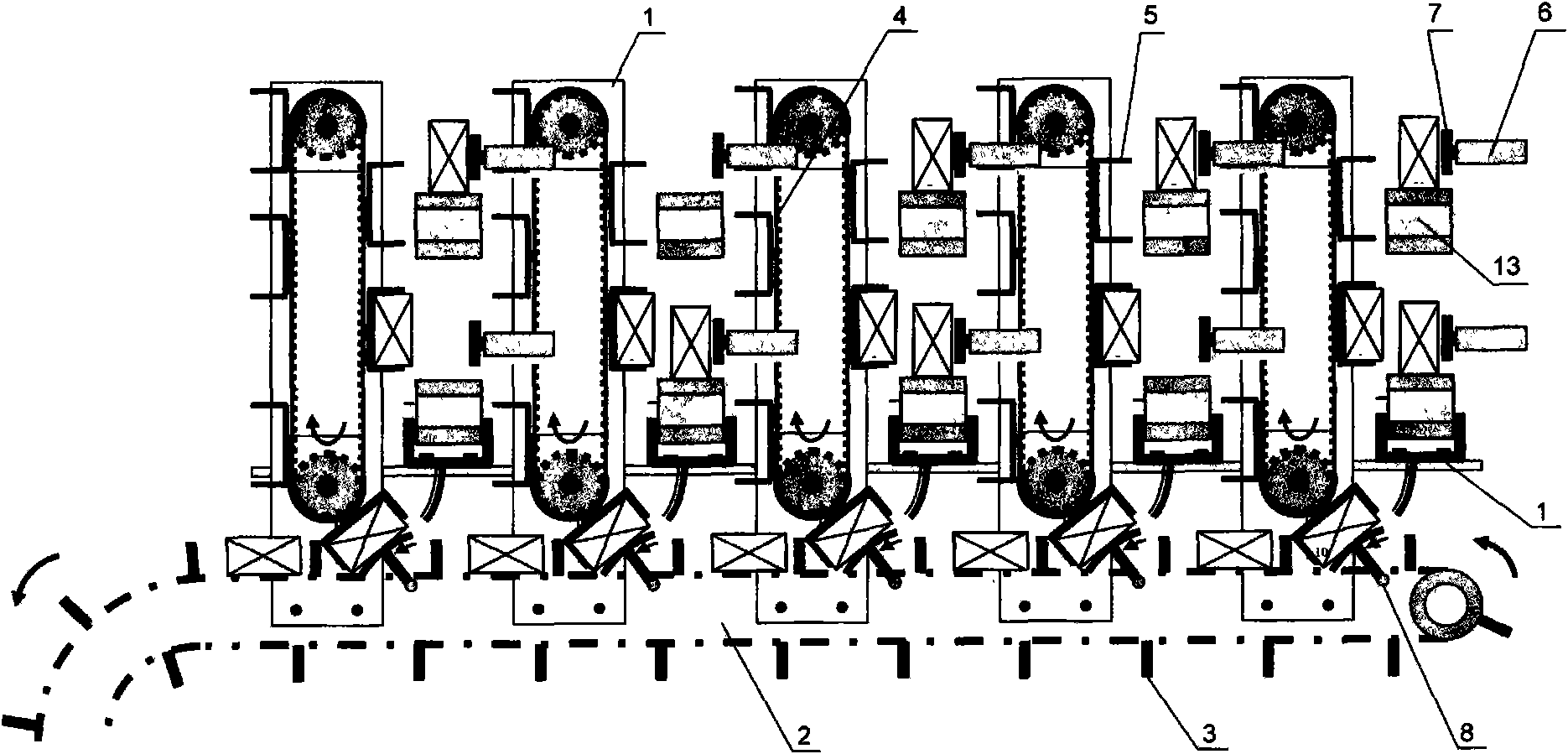

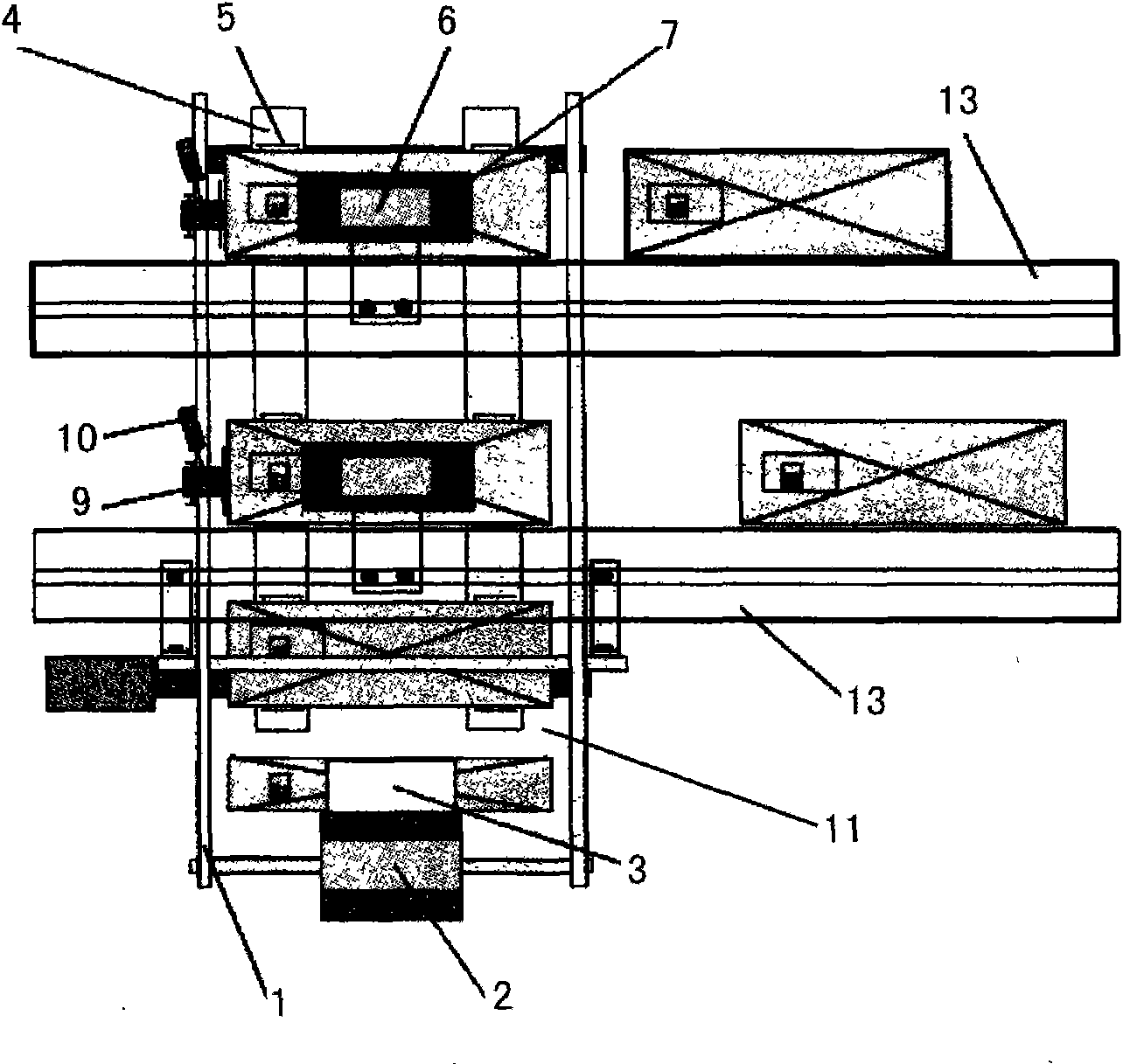

[0027] see figure 1 and 2 The multi-channel tobacco rod collecting and arranging device 11 is arranged on the working surface of the tobacco rod conveying belt 13 located at the height of the workshop, and the tobacco rods sent by a series of tobacco rod conveying belts 13 are horizontally processed on the working surface located at the high altitude. Collected, and then discharged in an orderly manner to the regular separation unit on the horizontal descending conveyor belt 2 (chain plate conveyor belt or toothed synchronous belt) located below the outlet of the vertical synchronous belt 4, the tobacco rods will be transported by the horizontal descending conveyor belt 2 The discharged tobacco rods descend laterally and are transported to the entrance of the case packing and sealing machine 14 . On the working surface of the tobacco rod conveyor belt 13 located at high altitude, the frame 1 of the device is compactly fixed on the track beam of the tobacco rod conveyor belt 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com