Novel progressive safety tongs

A progressive, safety gear technology, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of wire rope breakage, high production costs, and large space occupation of speed governors, and achieve simplified structure and structure Compact and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

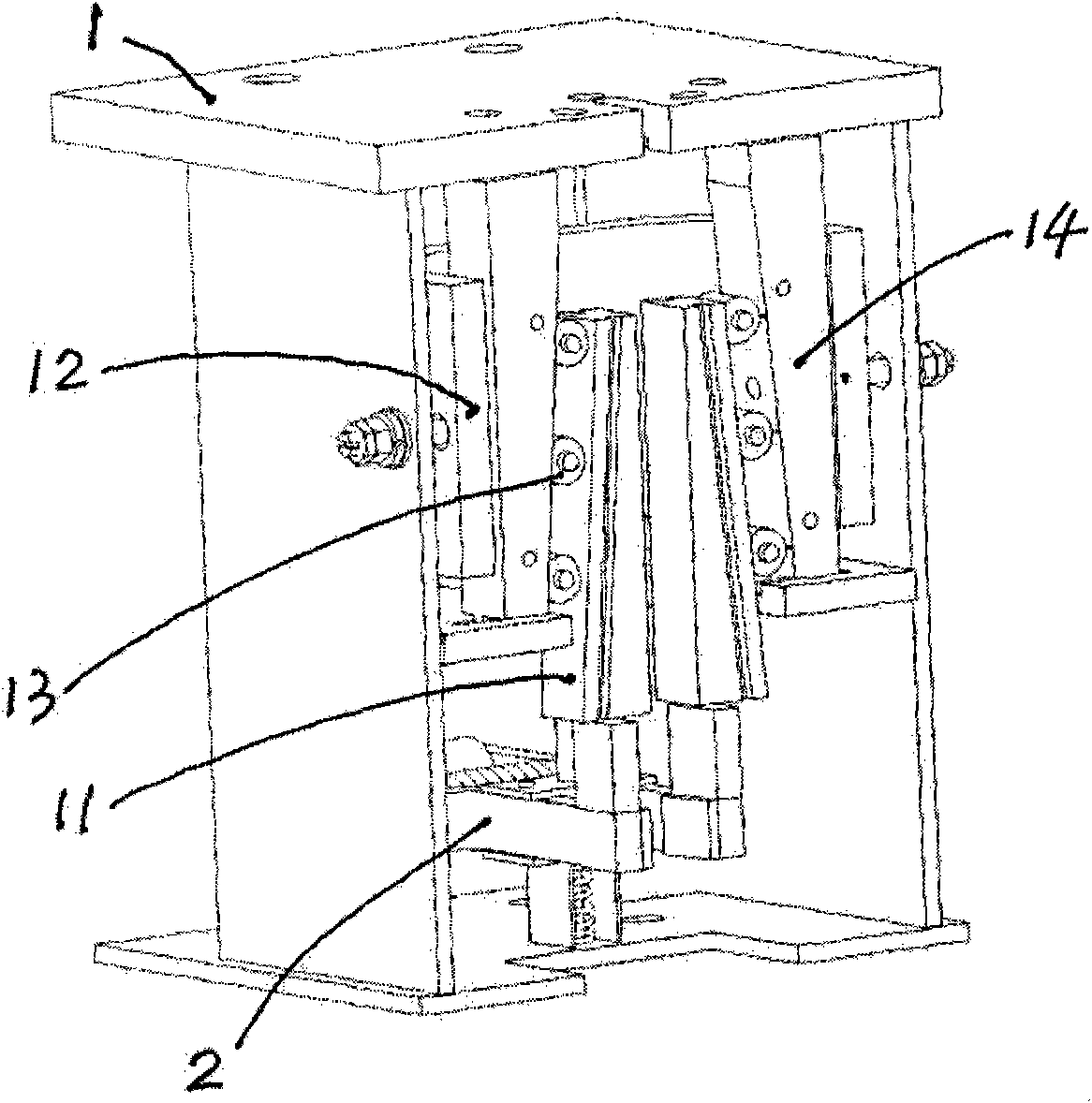

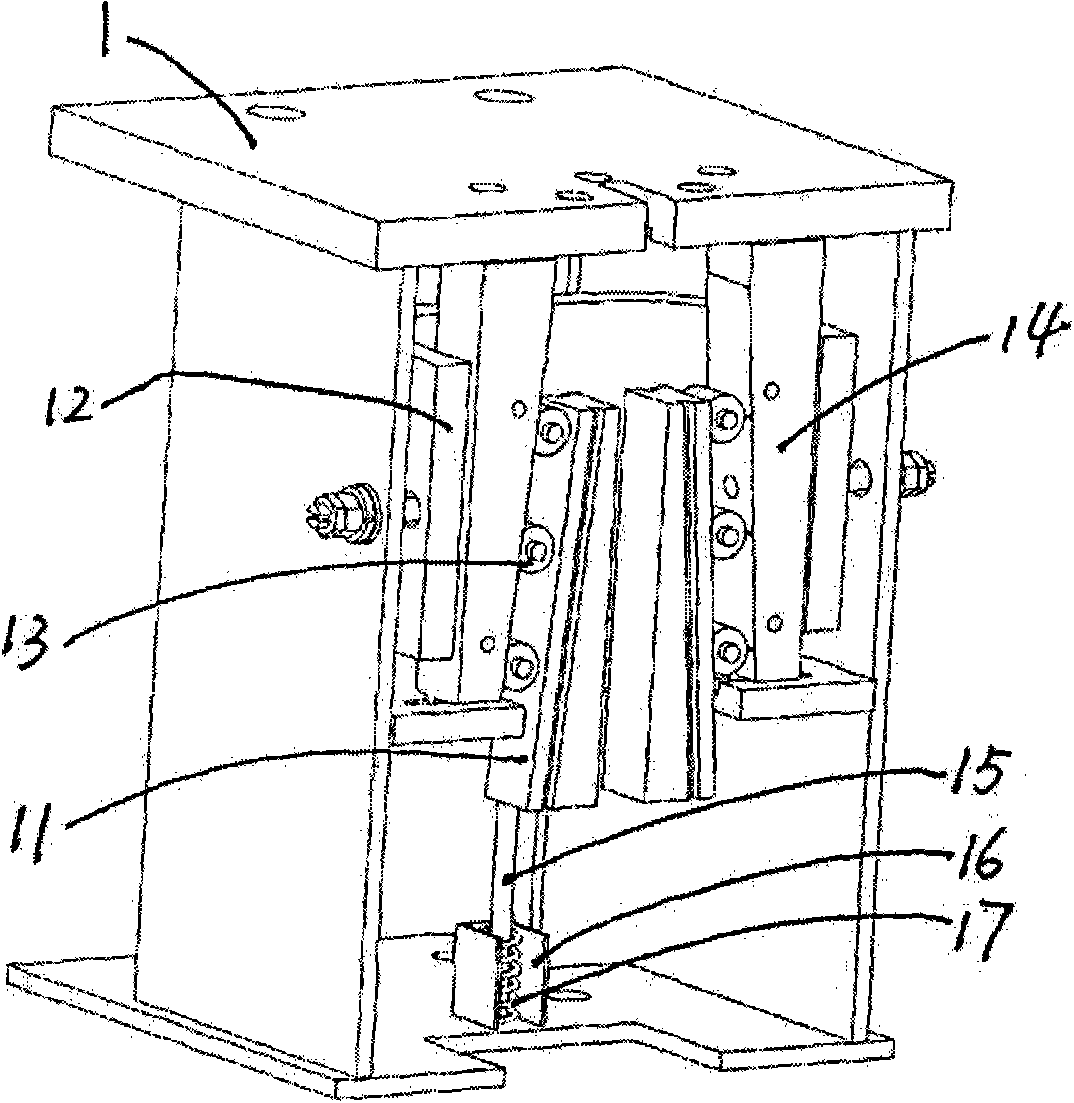

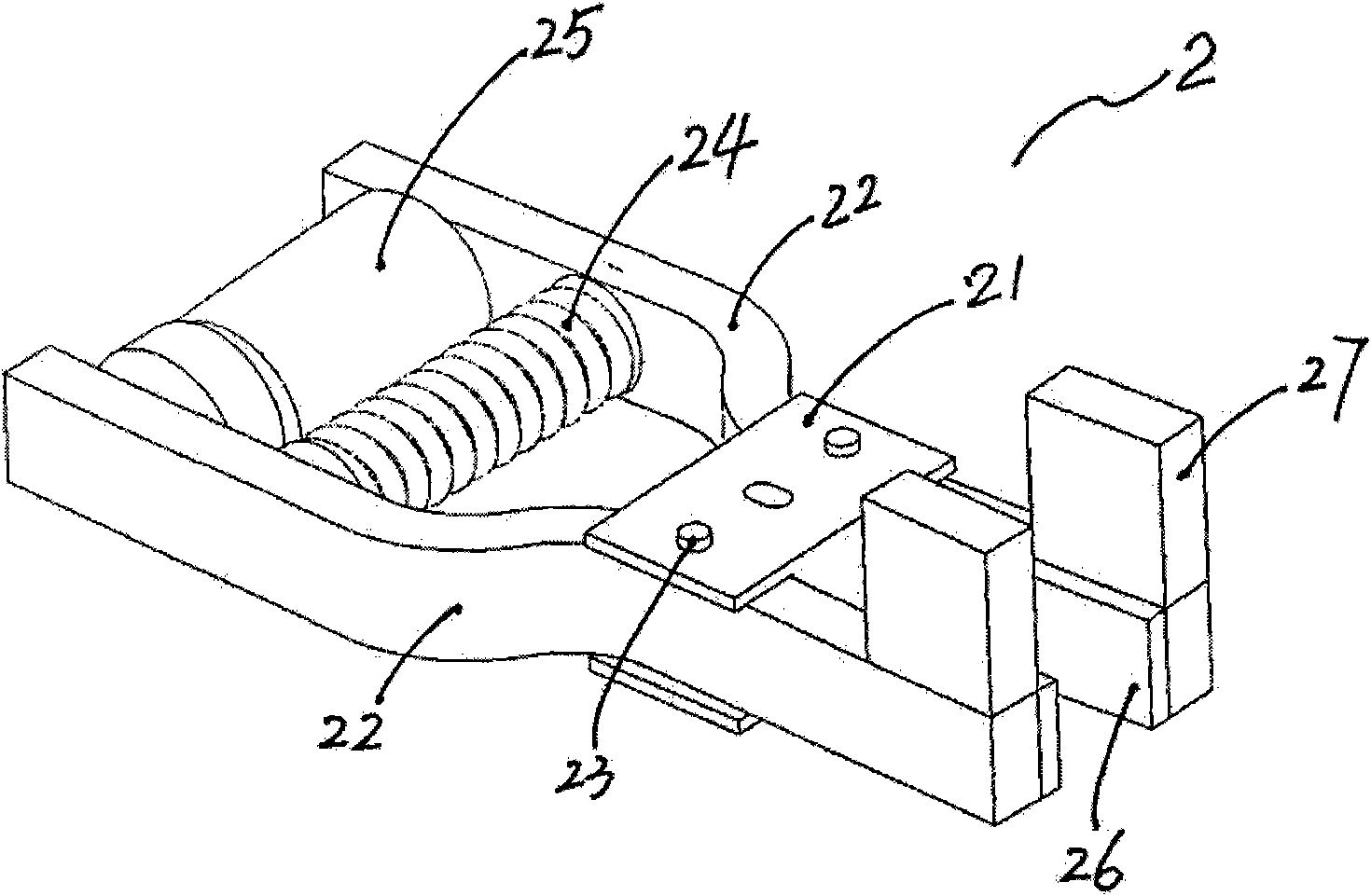

[0021] Such as Figure 1 to Figure 3 As shown, the novel progressive safety gear of the present invention has a pliers body 1, and a movable wedge 11, a U-shaped spring 12, a ball 13, a guide block 14 and a pushing mechanism 2 are installed in the pliers body 1. The pushing mechanism 2 is arranged in the caliper below the movable wedge 11, and is composed of a fixed base 21, two lever arms 22, a spring 24 and an electromagnet 25, and the rod body parts of the two lever arms 22 respectively pass through a pin shaft 23 Hinged on both sides of the fixed seat 21; the spring 24 is a compression spring, arranged between the rod bodies of the two lever arms behind the fixed seat 21; the electromagnet 25 is arranged on the rear end of the two lever arms 22, and the circuit of the electromagnet 25 is connected It is controlled by the speed limiter of the elevator; the inner surfaces of the front ends of the two lever arms 22 are all provided with brake shoes 26, and the upper sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com