Lift-drag complementary vertical axis wind wheel

A complementary wind wheel technology, applied to wind engines at right angles to the wind direction, wind engines, greenhouse gas reduction, etc., can solve the problems of small starting torque and limited development, to increase positive torque, increase efficiency, and increase wind The effect of wheel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

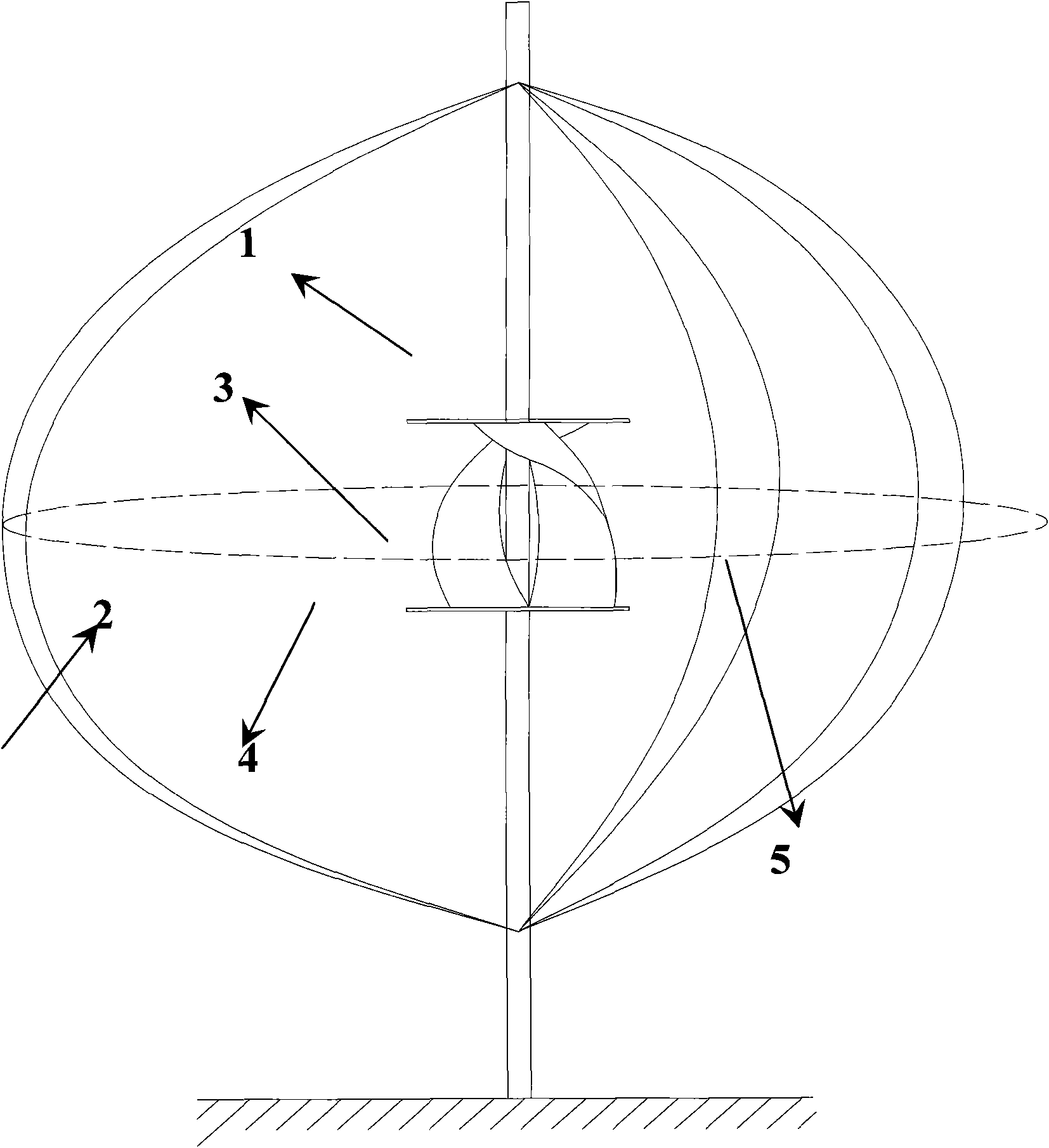

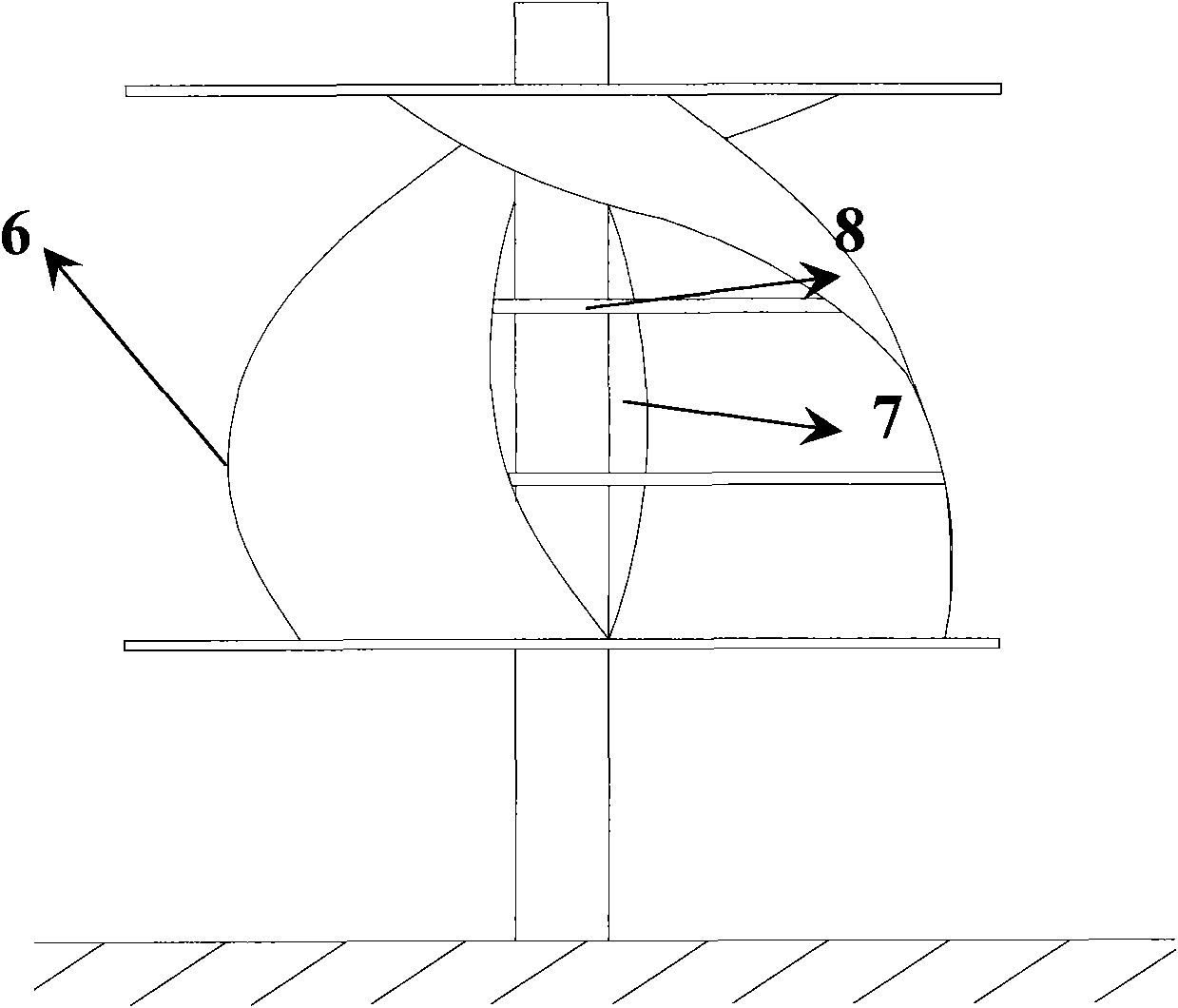

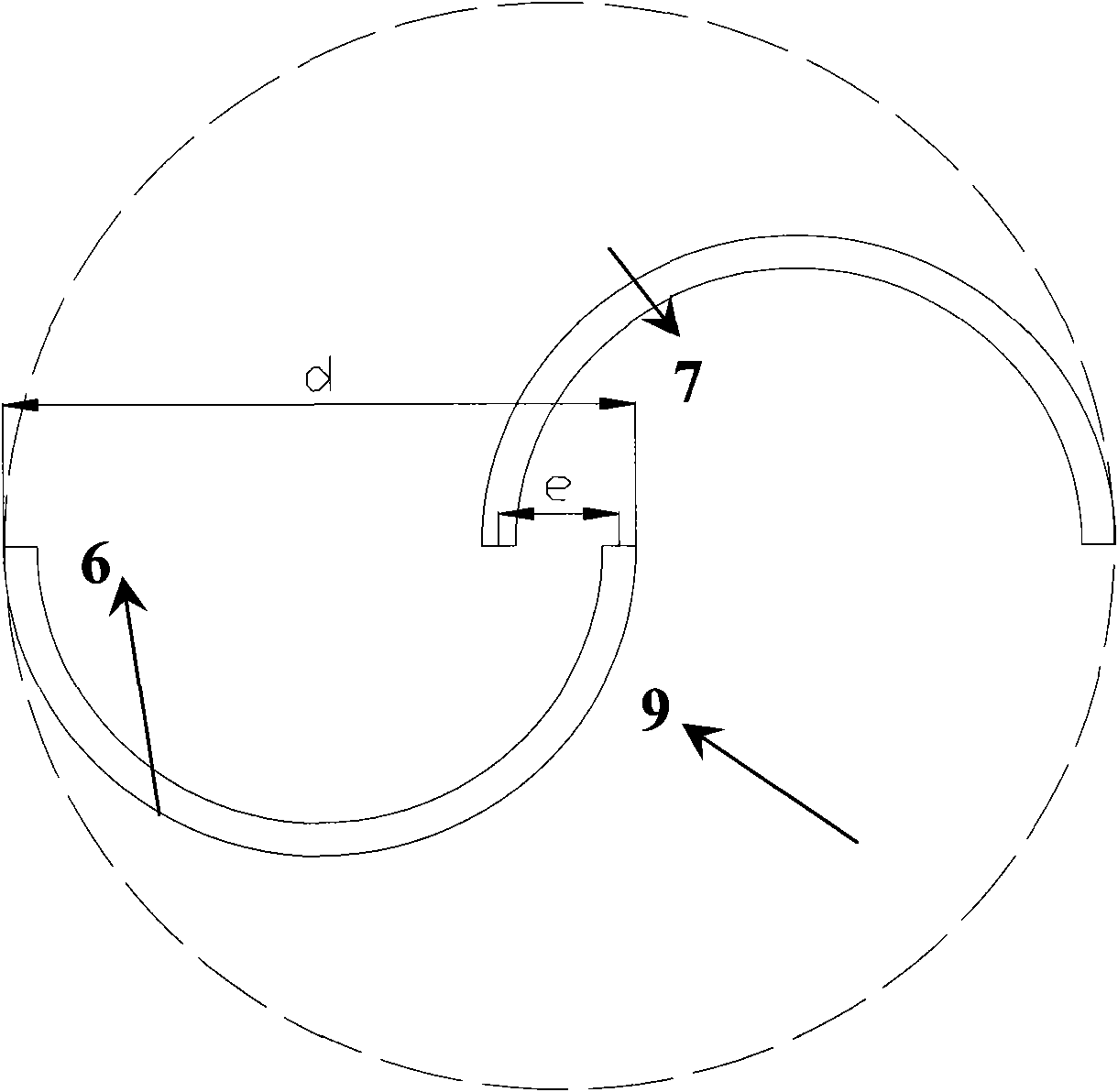

[0017] 1, below in conjunction with accompanying drawing, the present invention is described in detail, as figure 1 As shown, the lift-drag complementary wind rotor of the present invention includes a wind rotor shaft on which 2-3 lift-type blades 2 and 2-3 helical resistance-type blades 3 are installed. figure 2 It is a schematic diagram of the structure of a spiral resistance type blade with an end cover 4 and a partition plate of 2 blades. It is composed of a convex blade 6 and a concave blade 7, separated by 180° in the axial direction, and the cross-section is S-shaped, such as image 3 shown. The spiral resistance blade is formed by rotating the S-shaped blade at a certain angle along the shaft 1 of the wind rotor, and the blade rotation angle is 90° to 360°; the ratio of eccentricity e to blade diameter d (eccentricity coefficient) is between 0 and 0.4 ; The two ends of the blade are provided with a cover 4, and the ratio of its diameter to the rotation diameter 9 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com