Flexible supporting structure for the back of reflecting mirror

A flexible support and support structure technology, applied in installation, optics, instruments, etc., can solve the problems of increased mirror mass, increased mirror weight, and reduced light weight, achieving the effect of simple and reliable operation and avoiding assembly stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with accompanying drawing:

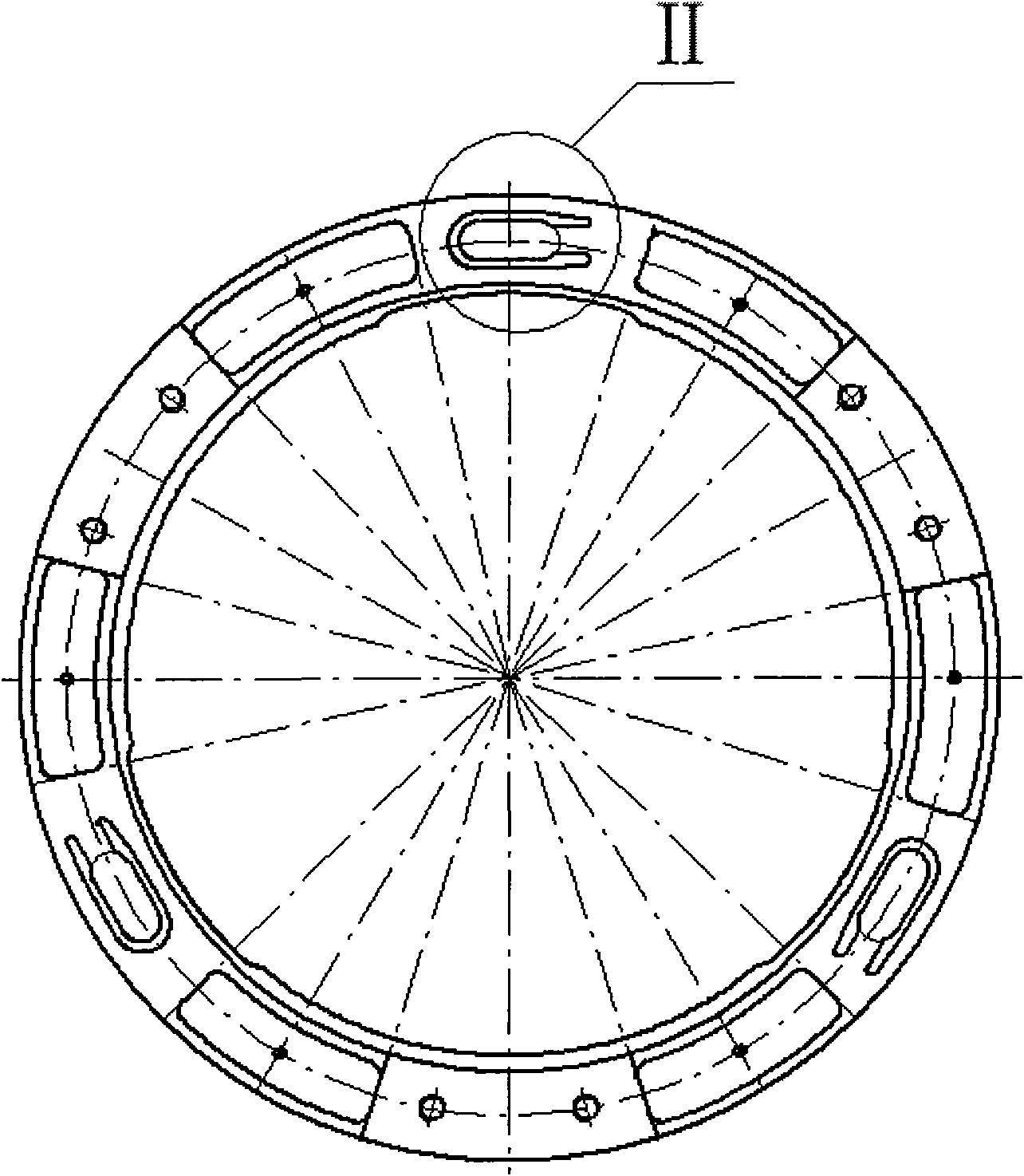

[0018] Such as Figure 1 to Figure 8 As shown, a kind of reflector back flexible support structure of the present invention comprises an upper ring 1, a lower ring 2, a first flexible part 3, a second flexible part 4 and a third flexible part 5, and the upper ring 1 and the lower ring 2 are The metal rings parallel to each other are connected by three flexible parts forming an angle of 120°. The lower ring 2 is bonded to the back of the mirror, and the upper ring 1 is fixed on the corresponding position of the camera body through the back plate.

[0019] The horizontal projection of the first flexible piece 3 is shown in view II, and the sectional projection is shown in view III. The structures of the horizontal projections and sectional projections of the other two flexible pieces are the same as those of the first flexible piece 3 . The projections of the first flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com